Diesel of the Week is presented by

Tameless Diesel Performance has been serving the Asheville, NC community for 6 years now, providing a variety of quality automotive services. The shop mainly focuses on diesel repair and performance work, but also dabbles in gas applications from time to time, such as LS-based projects.

According to owner Aaron Reynolds, Tameless Diesel runs a four-bay operation with plans to upgrade soon to a 15,000 sq.-ft. facility. Even now, the shop has more than enough work coming in. With a chassis dynamometer in-house, the team is able to complete a range of tuning work for their customers as well.

“We actually have the same chassis dyno that Ryan Milliken has, so we do a lot of tuning with him,” Reynolds says. “But, aside from that, we do all three of the Cummins, Powerstroke and Duramax platforms – old and new. Occasionally, we’ll work on some heavy-duty stuff like Class-A trucks, but we mainly focus on pickups.”

Reynolds began his foray into the diesel world in 2008, when he purchased his first truck. Back then, he was building houses during the day and working on diesels at night. Now, he’s flipped businesses and builds trucks during the day and builds houses on the side. That switch gave him more time to work on performance builds, like his current race truck – a ’94 Dodge Ram 2500 with a turbocharged 6.7L Cummins engine.

The truck was originally bought from a friend, and then outfitted with a ton of new upgrades to regain its former glory. Reynolds said this is one of the “OG” Pro Street trucks that hit the track back when diesel racing boomed in the late 2000s.

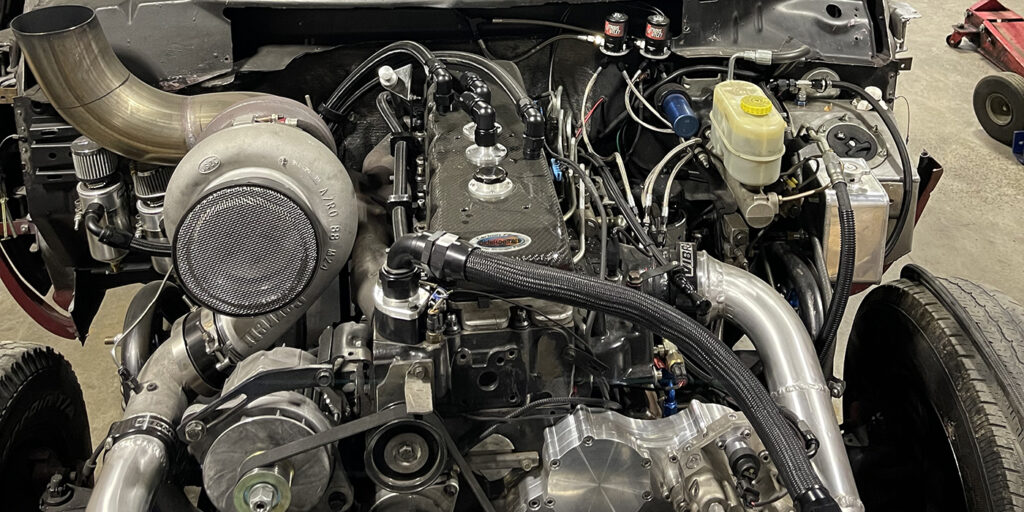

The first step was dropping a new engine under the hood, and Reynolds settled on a 6.4L powerplant based off a 6.7L block. The Fleece Performance motor formerly sat under the hood of Ryan Milliken’s “Mini-Wheat” truck, until the long block was transferred to Reynold’s new ride.

“It’s a Fleece block with all their modifications, and obviously it’s sleeved and has their racing head on it. There’s a Beans Machine triple CP3 front cover on it that runs injection pumps and stuff, and a Hamilton camshaft.”

Wagler connecting rods and Diamond pistons were added, with most of the other bottom and top end components coming from Fleece. The fuel system was another major addition Reynolds made, including S&S injectors, 14mm injection pumps, and a new SP3000 fuel pump that got mounted on the front.

Reynolds opted to only use a single turbo for his setup, however, the Garret GTX55 Gen4 is paired with a large amount of nitrous to compensate.

“As far as how much we spray, I’m not sure,” he says. “But, we run two 15-lb. bottles through a progressive controller. There’s seven jets plus a Nitrous Outlets intercooler plate, then we have four solenoids on it.”

All in all, the truck makes around 1,800 horsepower and Reynolds intends to increase that number after some suspension issues are ironed out. Reynolds has raced it in ODSS events and ran it in Lights Out this year. The fastest it’s run to date is 5.51 at 136 mph in the eighth mile.

“It’s a pretty simple setup, but it works well for us.”

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].