Diesel of the Week is presented by

A few weeks ago, the Engine Builder team traveled down to Canton, OH for a visit to Zeigler Diesel Performance. Frequent readers will be familiar with the name, as we’ve featured owner Justin Zeigler and his high-octane escapades a few times in our Diesel of the Week series and other areas of Engine Builder. Non-frequent readers will likely still recognize the name, as Zeigler is a growing name/brand in the diesel world.

Winning the Ultimate Callout Challenge last year was a big win for him, proving his expertise in diesel motorsports and engine work. When he’s not preparing his own racing machine, he’s managing his business and completing general repair and performance work. When we stopped in, he was building a new Cummins engine for Travis Richards, a close friend who went to Diesel Power Challenge with Zeigler a few years ago.

“We do all his engine work, tuning and everything like that,” Zeigler says. “This is going in his personal race truck and it’s going to be a good, all-around street toy that he’s going to beat the snot out of with a big single charger and a bunch of nitrous.”

Zeigler added that Richards mentioned driving the truck this year at King of the Street, where he’ll be competing in racing, pulling and dyno events. As with any event of this nature, a solid diesel engine is needed to keep up with the pack and be competitive. A Cummins engine was the obvious choice.

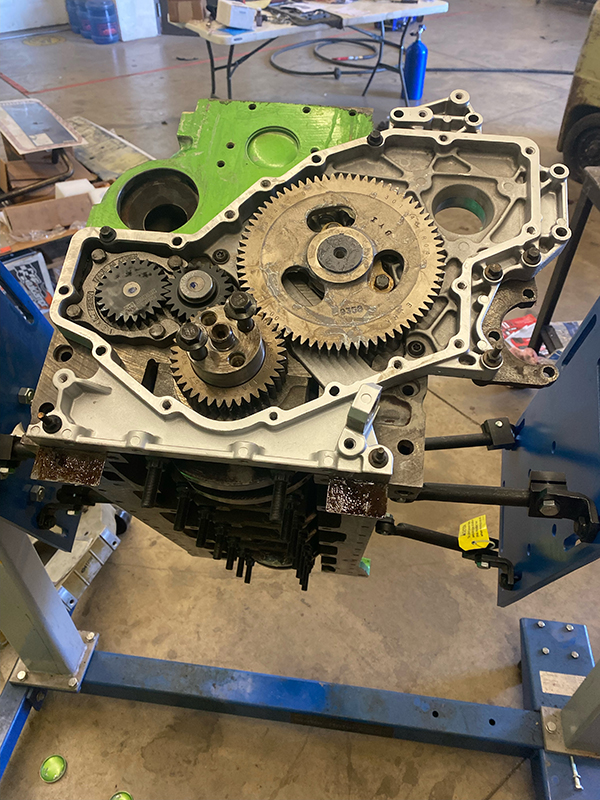

For the build, he used a 6.7L Cummins block with a 5.9L crank and pistons bored .020″ over. The billet rods come from Wagler, which Zeigler said are a great package for the 6.7L – 5.9L combo since they are .080″ longer.

“The 6.7L block is just naturally stronger,” Zeigler says. “I’m a fan of doing what they call a 6.4L motor, basically a destroked 6.7L. It seems to be a lot easier on parts and a lot less rod angle.

“This engine package is a good all-around, strong setup without going the full bore, doing sleeves and the deck plate and everything else. It’s kind of like your budget, safe way to make 1,300-1,400 horsepower and it’ll live a pretty good, long life.”

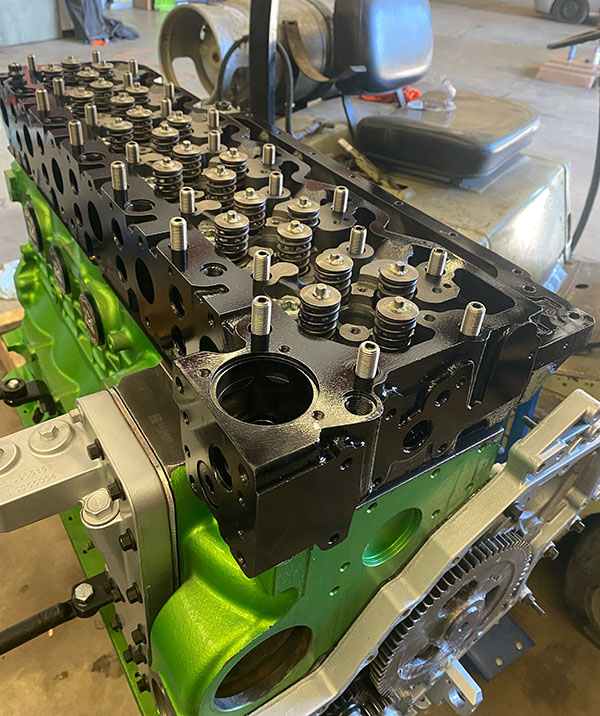

The engine also features an Industrial Injection Gorilla girdle, a steel Hamilton 180/220 camshaft, and ARP hardware throughout. The tappets, valve springs and pushrods also came from Hamilton.

D&J Machine did all the head work, and local Angeli Machine in Canton took care of the machine work. Zeigler also built the transmission and the transfer case for the truck in-house.

“For the turbo, as far as I know it’s getting a single S480 billet charger, and a couple kits of nitrous we’re going to help him setup. I don’t know what he’s doing injector wise yet, rumor was he was going to go with a set of F1 Diesels 200% over injectors. It’ll also have dual pumps and the normal, basic stuff that most guys are doing.”

Now that the engine and transmission are finished, Richards just has to put it all together in his race truck. Once he’s done, he’ll be traveling to Canton for a tune at Zeigler’s and some test runs.

“I want it to make right around 1,200 horsepower on fuel,” Zeigler says. “If he follows my lead and we do a big external gate and some things the way I want, we should be able to spray it and get around 1,400 or 1,500 horse easy.

“It’s definitely going to get used and abused, so we didn’t spare any expense in order to do it right.”

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].