Diesel of the Week is presented by

That first step into the engine building world is arguably the hardest, as there’s often a few hurdles newcomers have to face. The costliness of the endeavor is likely something that will be considered early on, as well as the amount of time invested in a project. Those considerations don’t even come into play until the biggest hurdle is already met – learning to work with engines in the first place.

Most of the guys and gals we talk to spend a good portion of their lives in the automotive world before getting into serious, juiced-up builds. Working as a general repair mechanic or other similarly aligned role gives future builders the early skills to make an easy transition into the more technical world of engine building. Some people, however, go in with only passion and learn as they go.

Travis Trent is one of those people who has no formal training in a shop, but has amassed a great list of accomplishments on the track with his build. He owns Trent Heating and Air, a small business in Port Clinton, OH, and turns wrenches in his free time. Even though it’s side work, he’s qualified and competed at UCC and built one hell of a race truck.

“My friends and I were into it back in the day and I think I liked it a little more than they did, that’s why I’m still doing it,” Trent says.

The truck in question is a 2WD Ford F-250, which came from one of Travis’ friends, Chaz Slauterback. Soon after getting the truck, Trent dropped in a 5.9L Cummins that he had built that took the truck to UCC in 2018 and 2019, making 1,375 horsepower in the latter year. After no racing in 2020, he elected to buy a new engine for the truck rather than build another. For this, he went to Pine Hill Auto, a full-service diesel truck repair and performance shop in Carrollton, OH.

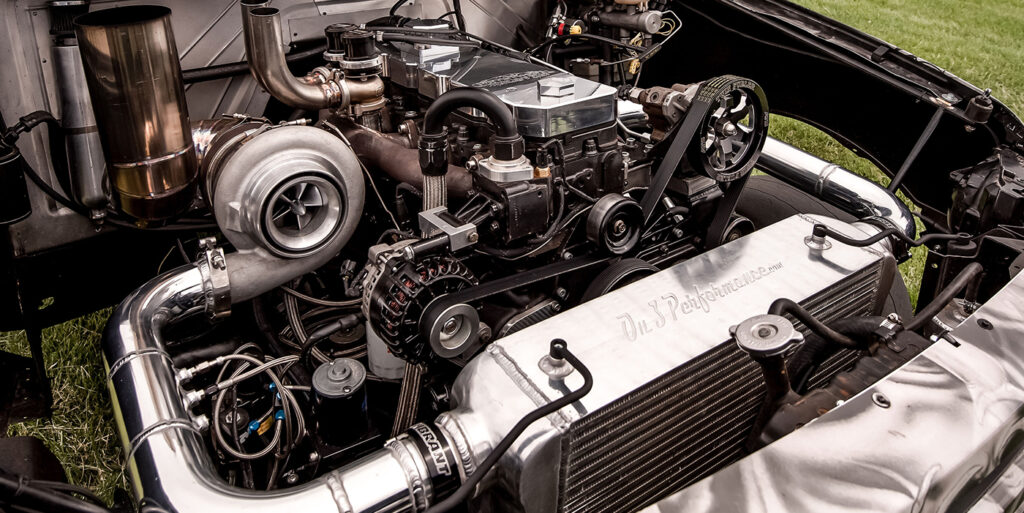

“It’s a 6.7L deck-plated Cummins,” Trent says. “It’s a full sleeved engine with a custom ground cam that Hunter from Pine Hill spec’d out for me.”

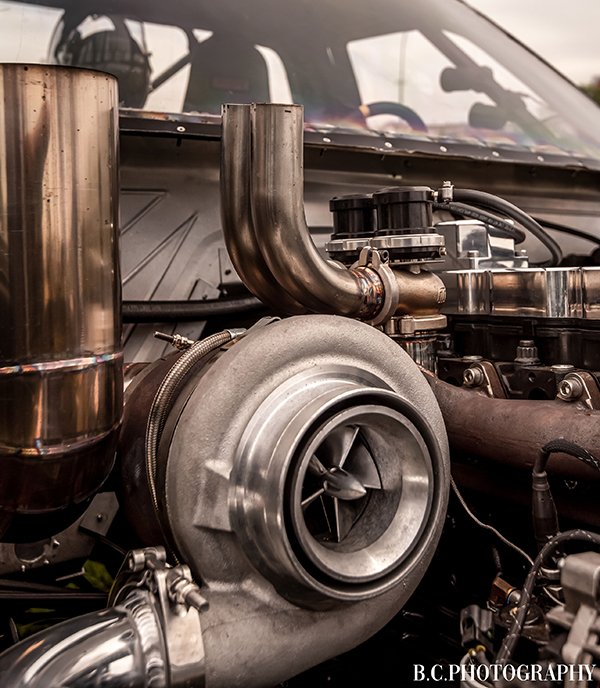

The engine rocks 1″-longer Wagler rods, D&J Precision billet pistons and a full main girdle on the bottom end. ARP studs fill it out top to bottom. A single Stainless Diesel S485 Godfather turbo commands the air flow and the engine produces roughly 400 extra horsepower with the amount of nitrous Trent sends through it.

For fuel, he uses massive 400% fuel injectors given to him by one of his sponsors, S&S Motorsports. These are paired with a FASS fuel system for optimized fuel delivery.

Other additions to the engine include a billet valve cover and thermostat housing from G&R Diesel. After being tuned by Firepunk Diesel, the truck sits right around the 1,800-horsepower range, although Trent and friends have envisioned it making upwards of 2,500 in the future. Last year, the truck went 5.67-seconds in the 1/8th-mile.

“It would’ve never gotten to that point without some help from people along the way,” he says. “Wyse Auto built me a great transmission and my best friend Kyle Lucas at API Fabrication helped a ton. The rest of the guys on my team, Chaz who I bought the truck from, and Dylan Terry also did a lot.”

Trent is looking to go to Summit Motorsports Park soon, but he mainly races the on the ODSS schedule and is looking forward to UCC 2022.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].