If there’s one thing we know about the diesel crowd, it’s that you folks like to have fun! And what’s more fun than huge turbos and nitrous, am I right? Of course I’m right. But, it’s not fun blowing up your engine because you didn’t utilize the right combination. To get some extra insight into the different levels of turbos and nitrous systems today’s diesel performance guys are running, we spoke with Lavon Miller of Firepunk Diesel.

“Turbo setups really come down to personal preference,” Miller says. “Here at the shop, we have our favorite setups and stuff that we put together that we feel drive nice. Those are ones we’ll sell to guys. I’ve also put setups together that customers have asked for and they just don’t drive all that nice. Most of our recommendations come from personal experience and stuff that we’ve found over the years. However, you can do it 15 different ways.”

There’s a lot to take into consideration when it comes to putting boost to your engine such as driving style, the application of your truck, your elevation, and how much power you ultimately want.

One of the easiest upgrades to turbocharging is the stock appearing market. That is where you can take the stock turbo off and replace it with another turbo that fits in the exact same location – same down pipe, same oil feed, same oil drain, same intercooler pipe – it just has upgraded turbine wheels and compressor wheels in the stock turbo housing.

“That’s a big market because it’s something guys can do at home in their garage,” Miller says. “It’s an easy bolt-on configuration. There’s no welding required and there’s pretty good power gains to be had out of those little stock-appearing turbos. They still tow good. They still spool decently fast. We’ve had guys make as much as 900 horsepower with those when you put big fuel systems on.”

The majority of guys have a stock fuel system and want a little bit of a turbo upgrade, so popular options are something like Fleece Performance’s Cheetah turbo, or stock appearing turbos from Tater Built Turbos, Stainless Diesel, or Calibrated Power and its Stealth 64mm.

“Most of those turbos are a bolted-on 63mm stock-appearing turbo and will support up to 650 horsepower,” he says. “Bang for the buck, that’s probably your best, most-common turbo upgrade. Beyond that, guys go to the single S400s.”

According to Lavon, it’s pretty common for guys to do what’s called a second gen swap. They take the third gen manifold off because the third gen has the T3 manifold pointed down and in a lower location. The S400s don’t fit down there, so they put a second gen manifold on and move the turbo up in the center.

“You have to have a new air intake, a new intercooler pipe, a new down pipe, a new turbo drain, and a new oil drain – it’s a $3,000 setup to get a second gen swap on your truck because everything is custom,” Miller says. “That said, it gives you a wide range of turbo options. You can buy anything from a 64mm S400 that still spools relatively quickly, still tows trailers nice and supports 750 horsepower, or you can bolt up to an S485 on there, which will support over 1,300 horsepower as a single turbocharger. That swap gives guys a lot of ranges.

“Guys will start with an S467, which is a common turbo – 67mm compressor wheel / 83mm turbine wheel and 9.0 exhaust housing – that will support 800 horsepower and still drive relatively nice. Once guys go to bigger fuel systems, they’ll take that S400 off and put an S475 on, which will make 1,000 horsepower. If they want to step up from there, an S480 is an option.

“Once you go bigger than a 72mm compressor wheel, you really start getting into the big single range where what you gain on the top end, you lose on the bottom end. I don’t like daily driving a street truck that has a 75mm turbo on it. It’s not that fun. You just don’t have a lot of mid-range. You can easily drive to town and get ice cream, but there’s no good mid-range power. You’re either just driving nice or you’re going full throttle and getting rowdy.”

For those reasons, a lot of guys try to get more horsepower out of a larger turbo, but ultimately resort back to something smaller to keep the drivability. Sometimes that extra 100 horsepower isn’t worth the drivability that you lose because of it.

“Peak power isn’t always a breadwinner when it comes to choosing a turbo,” Miller says. “You have to figure out what your primary use is for your truck and then pick a turbocharger according to your primary use. If your primary use is daily driving and towing, pick a turbo that’s going to daily drive well and tow well. If it doesn’t make as much horsepower as you want, that’s the compromise.

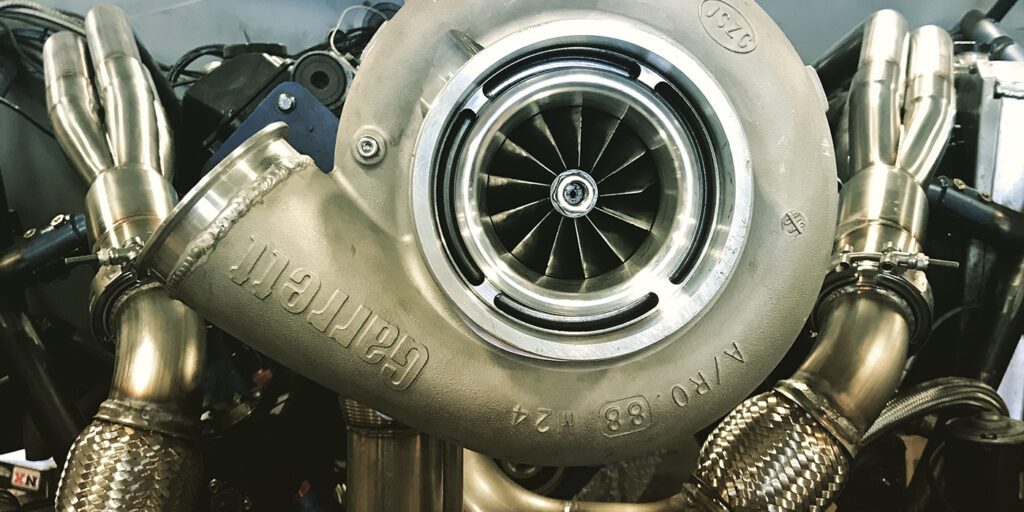

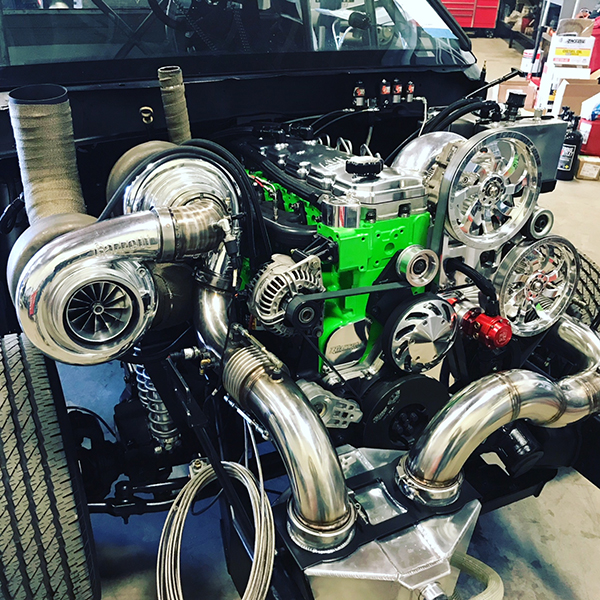

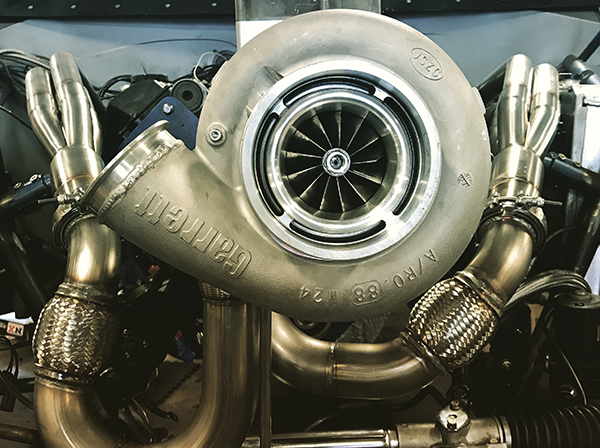

“If you want the best of both worlds, you almost have to go to a compound setup, which gives you the ability to have a small manifold charger that makes quick boost at the low rpms, but you also have a big charger that thumps in good, clean air at high rpm ¬– you get a lot wider power window. You can make really good power from 2,000-4,500 rpm with a set of compounds. Whereas a bigger single won’t make great power at 2,000 rpm. It really won’t come into power until 2,800-3,000 rpm, so you miss out on that bottom range where a Cummins generally operates.”

The most common compound turbo setup Miller has seen recently is a stock turbo with an S475, which is common for the street and the tow guys. The other is an S468 over an S480 or S485.

“Those S400/S400 compound setups have become fairly popular,” he says. “If you put an S468 over an S480, you’ve got a solid setup that can still drive nice, tow nice and support 1,100-1,200 horsepower, depending on what your atmosphere turbo is.”

Generally speaking, these days, folks have figured out that compound turbo setups can offer the best of all worlds if done correctly for an application. However, you still see a few trucks running triple turbo combinations.

“Triple turbos are a two-stage configuration, you’re just taking that monster atmosphere turbo and splitting it up into two smaller turbos that spool faster,” he says. “You could either have a 107mm atmosphere charger, or you could have two 68mm atmosphere turbos that would flow the same pounds per minute and they would spool faster than the 107 would. The triples give you a wider power band if you want to make big torque, but still support more.

“What we found after quite a few different sets of triples back in the day is that a big set of compounds is typically better. Once you fabricate a set of triples and you keep oil feeds and drains and take them apart and put them back together a couple times – the triples are a real pain in the ass.”

Just like the saying, “More money more problems,” the same can be applied to turbocharging your diesel, “More boost, more money needed.” Thanks to the experience Firepunk Diesel has had over the years, they’ve found different horsepower breaks where certain upgrades are needed in your engine in order to keep up with what the turbo will offer.

“At the 800 horsepower mark, the stock long block really survives very well,” Miller says. “We see very few failures out of the long block or the heads in the 800 horsepower window. But, over 800 horsepower, we definitely recommend going to the ARP 625 head studs versus the less expensive ARP2000 head studs. Over 800 horsepower, we’ve had numerous instances of hearing the head gasket flutter on the dyno around 830-850 horsepower. The ARP 625 studs hold a head gasket up to about 1,000 horsepower. After 1,000 horsepower, we recommend going to a fire ring setup to hold the head gasket.”

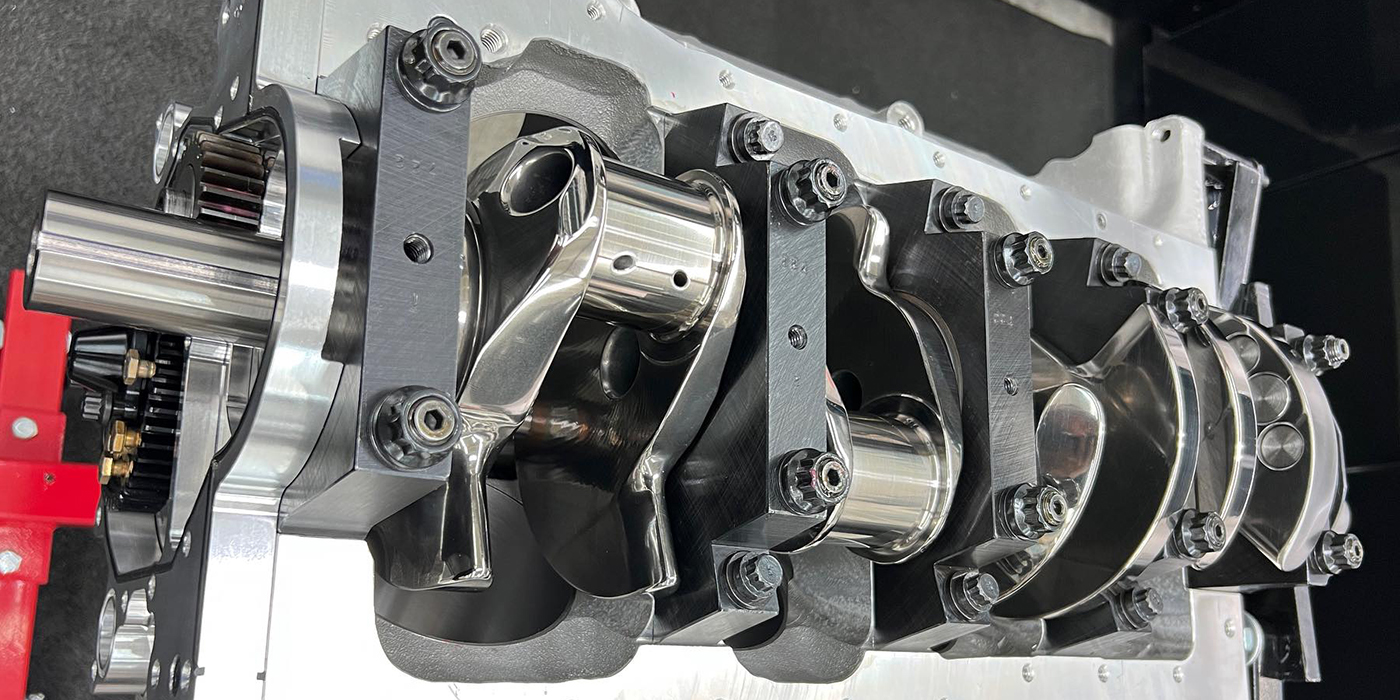

Aside from hardware changes, some of the rotating assembly parts such as rods and pistons can start to be at risk around 950 horsepower, and over 1,000 horsepower is when a number of other parts need attention as well.

“Generally, if your goals are over 1,000 horsepower, plan on getting a billet rod in your engine,” Miller says. “Once you have a billet rod, if you have an S400/S400 compound setup, you’re making 1,200 horsepower and 1,800-2,000 ft.-lbs. of torque. Now, you really need a girdle to keep your main caps from walking around, and much past 1,250-1,300 horsepower you have to worry about cracking the cylinder walls. That’s when you’ll see guys buying 6.7L blocks and sleeving them down to 4.125” bore. That gives you a lot stronger platform to keep from cracking the cylinder walls above 1,300 horsepower.”

As mentioned earlier, playing with big turbos is a blast, but the serious competition-level guys will want to add nitrous to the equation as well. It might sound easy to add nitrous, but if you don’t do it right, you could find yourself in some trouble quick.

“With nitrous, I see a lot of guys make the mistake of maxing out their setup,” Miller says. “They might make 1,100 horsepower with an S475, 200% over injectors and a 12mm CP3, and then they are scared of nitrous, so they just add a little 80 shot. They pick up 100 horsepower with nitrous, but what it’s done is it’s added your air/fuel ratio right into that 18:1, which is the hottest range of AFR that you can operate the engine in.

“You either want to be heavily over fueled in the 12:1-13:1 air/fuel ratio, or you want to pull fuel back and add two kits of nitrous and go all the way to the lean side of the curve, where you’re over 20:1 air/fuel ratio. There, you’re so lean that it’s actually cooling it off and is safer than maxing your setup on fuel and then adding a touch of nitrous, because you’ll just turn that flame into a torch and you’re more likely to melt pistons.”

What Lavon and Firepunk advise, is to dial back the fuel and go from 2,000 microseconds to 1,600 microseconds and then add two decent sized nitrous jets – maybe an 80 jet on the first kit and a 110 jet on the second – and spray it all the way to the lean side to get a bunch of oxygen, rich air in there. That’ll help make that 1,200 horsepower safer.

Speaking of safety, Lavon sees a lot of guys with nitrous on their truck blow up turbos because in the diesel world, no one is monitoring turbo shaft speeds, and a lot of these setups aren’t wastegated or running a boost controller. Eventually, every turbo has its limit of how fast it can spin, or the thrust bearing can’t handle the load – both result in explosions.

“A lot of customers will want to blame the turbo manufacturer for a failed turbo, but in reality, they were modifying their truck completely blind,” Miller says. “They had no idea what the boost number versus drive pressure was or what the turbo shaft speed was and they don’t know why it blew up. If you really had the data to be able to see what was going on, you’d know the turbo was at 135,000 rpm shaft speed. It had no chance. You need to put a bigger exhaust housing on it if you want to run that much nitrous, or you need to put a bigger exhaust turbine in the turbo in order to flow more air to slow the turbo down.

“There’s a lot of data missing in the hands of the general diesel enthusiast for these street trucks, because it’s so expensive to get good data acquisition systems on these trucks that could actually log all that stuff. That’s why here at Firepunk, we try to use our race data. Our race trucks all have data acquisition systems on them for AFR, wide band O2 sensors, turbo shaft speed sensors, etc. We do all this testing to have a better idea what to recommend to the customer for their end goal without needing them to spend the money on putting all that data acquisition on.

“We try to set the customer up for success in the beginning. That’s where it’s really helpful to take the advice of somebody who has already been there, done that. Unfortunately, a lot of guys just throw stuff together, throw a nitrous bottle on it and then they get a pile of broken parts, and they’re left wondering why.” EB