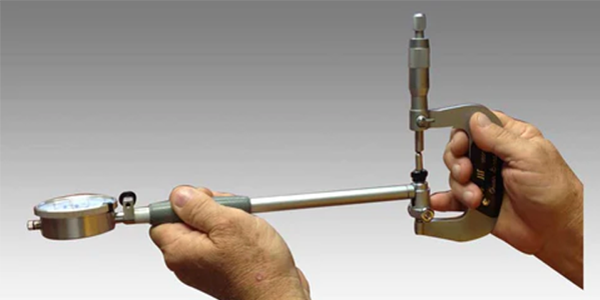

This popular dial bore gauge setting fixture is FINALLY back in the product line. We’ve been searching for a replacement direct reading micrometer for what seems like ages, and at last we’ve been successful.

With heavy, billet steel construction and a quality Mitutoyo micrometer, you can set the dial bore gauge quickly and accurately between 2″ and 6″. It will work with most popular dial bore gauges including Mitutoyo, Phase II, Fowler and Peacock.

Dial Bore Gauge Tech Tips

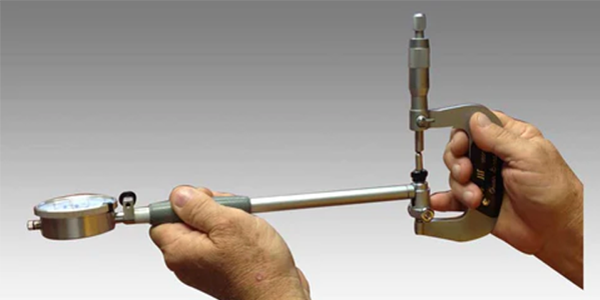

Goodson has found that one of the more difficult ways to set a dial bore gauge is manually. You’ve probably done this – you hold a micrometer in one hand and the dial bore gauge in the other. Sounds simple, but it gets pretty tough to zero the dial reading when both of your hands are already busy. All you need is a third hand!

Machinists, being the inventive folks they are, have come up with some tricks to get around this problem.

Most shops have a vise on the bench that can be used to hold the micrometer steady. Just be sure to wrap the mic in a shop towel or use a vise with rubber pads so that you don’t damage the mic. This simplifies the process since your vise is acting as that third hand. You’ll still need to do a bit of a balancing act to zero the dial because the round point on the gauge extension is going to want to slide off of the micrometer spindle.

A quick (and inexpensive) trick to make this a little easier is to slip a short piece of 1/4” ID hose over the micrometer spindle. Let it extend just enough to let the tip of the extension slip inside, stabilizing the whole assembly. Now this is not going to hold the dial bore gauge all by itself but it will make it harder for the extension and the spindle to slip apart. Don’t worry, this little piece of hose won’t affect the reading of the micrometer or the dial bore gauge.

Another quick tip that came from an old machinist is to mount the dial bore gauge in the vise and apply the micrometer. In this case, you’ll be rocking the micrometer instead of the dial bore gauge, but you might find this works better for you. Again, be sure to protect the shaft of the dial bore gauge from damage when you mount it in the vise. This technique will also work with a Micrometer Stand.