Electronic Fuel Injection (EFI) is all the rage today and rightfully so. EFI has many advantages that allow us to dial in the fuel in a dramatically more precise fashion than was ever possible with a carburetor. One of the tools at our disposal is the closed loop algorithm where the target air/fuel ratio commanded in the ECU is compared to the actual air/fuel ratio read by the O2 sensor. If the two do not match, the ECU makes small changes by either adding or subtracting from the commanded fuel in the fuel table to equalize the two.

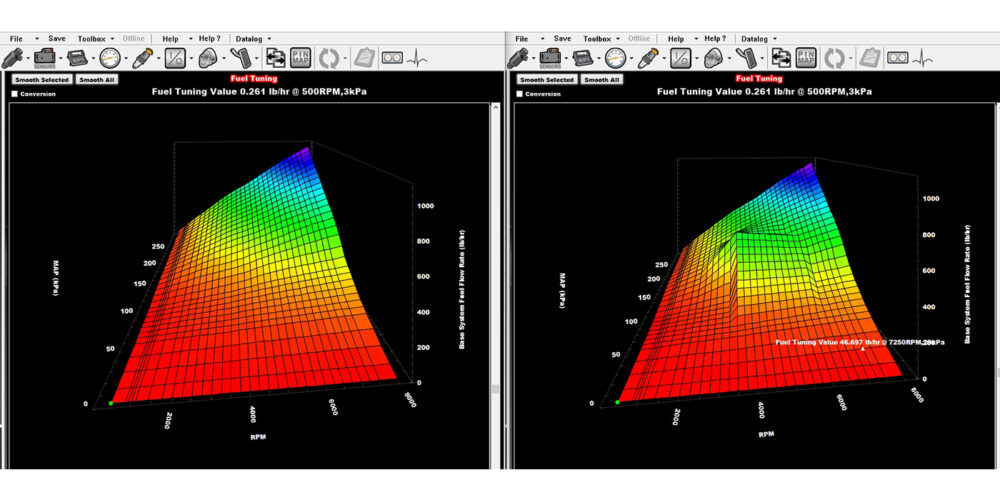

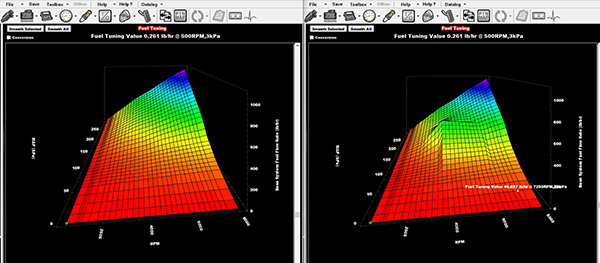

Unlike a carburetor that uses one jet to set the entire fuel curve, EFI has what could be referred to as a jet table. This multi-celled table has a fueling value based on a certain load and RPM point (or TPS and RPM point when tuning in Alpha-N). When correctly adjusted, it will for the most part, provide the required fuel to the engine to meet the target air/fuel ratio. But, a single, two-dimension fuel table or even multiple fuel tables working in unison, cannot always provide the exact fueling that an engine (which lives in a dynamic state) requires. This is where O2 sensor feedback, or closed-loop control, is so valuable.

Closed-loop control can be programmed to either add or subtract up to a certain percentage of fuel in order for the engine to reach the target air/fuel ratio. Astute readers may have noticed that I mentioned closed-loop control should only make small changes to fueling, and for the most part, this is true. But when it comes to a racing application, this is particularly important. In racing, closed loop should not be considered a long-term tuning tool, and ideally, we want only a maximum deviation of 1 to 2 percent between target and actual O2 readings during wide open throttle.

The primary reason for this low maximum is that closed-loop control is a reactive process and relatively slow. Consider this – by the time the exhaust event happens, the O2 encounters the data from that event, converts the signal, which is read by the ECU, which then calculates the correct fueling for that event and then changes injector pulse width – you have already accelerated past that fueling point. In other words, with O2 correction as part of the tune, you will never achieve the correct fueling for the engine, and therefore, not maximum power either.

Another scenario I see frequently are big swings in O2 correction in adjacent cells; where accelerating through a cell which needs -10 percent of the fuel removed then transitioning into a cell that will require +10 percent. When you keep in mind the latency of O2 correction, that second cell will naturally go lean, hurting power and possibly the engine before O2 correction has reversed. This also plays a part in throttle tuning and can be felt as a slowing in acceleration or a stumble. In any situation that requires excessive O2 correction, the fuel table needs to be corrected so fueling from cell to cell is ideal.

Fueling percentages are relative to the fuel number in a cell in that a 10% change in a cell commanding 200-lbs. of fuel is quite a bit less fuel than a cell commanding 500-lbs. of fuel. And correspondingly, the change from positive to negative correction will also take longer. Keeping O2 correction in the sweet spot of 1-2 percent is the job of the tuner and a must for any high-performance application. Since a little bit of O2 correction is always present, I have found it best to tune the fuel table so correction trends towards removing fuel, not adding.

Street driving can add a layer of complexity to tuning since we can observe larger swings in load as well as RPM, and therefore, fueling requirements. Setting the fuel map can be a compromise, especially when tight converters, low numerical gearing and heavy vehicles are involved. You can open up the O2 correction to help with some of these transitional situations while still keeping the correction at a minimum.

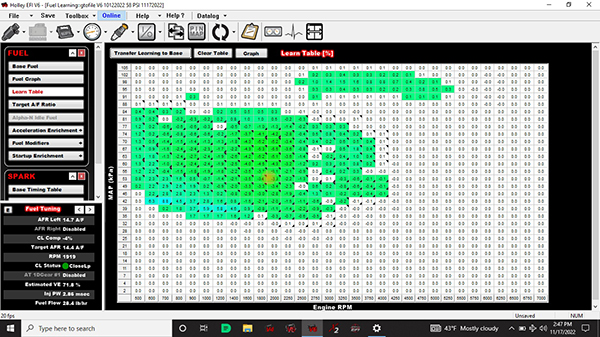

Fuel Learning is often confused with closed loop, but they are quite different, and here’s how. We can consider closed loop as short-term trim, while fuel learning would be considered long-term trim. Let’s explore the learn feature as designed into the popular Holley line of ECUs. When fuel learning is activated, the ECU will make closed-loop corrections as normal and then start to develop a background fuel learn table using the closed-loop corrections as a guide. Setting the gain of the learn function, controls how much of the closed-loop correction is added and how fast. The learn table is semi-permanent and works in conjunction with the fuel table to eliminate as much of the closed loop as possible moving forward.

The learning algorithm is unique in that it will not adjust fueling numbers in one cell, but rather blend fueling changes into multiple cells for transitional purposes. Because of this, learning requires that the initial fuel table be as smooth as possible for it to transition correctly. The learning feature is only designed to remove O2 correction in the fuel table and will not choose the correct target air/fuel numbers, timing curve, cranking fuel or any other user-defined table. These values will need to be optimized for each combination by the user to in order to experience the best performance the EFI system has to offer.

Finally, leaving the closed-loop correction and learn values at maximum limits can create drivability issues if one or more of the EFI sensors falls out of normal operating range. Using the analogy of garbage in garbage out – imagine a faulty O2 sensor stuck at a 20:1 air/fuel ratio – the closed loop and learn will add as much fuel as it is allowed, possibly to the point of flooding the engine with fuel. This can leave you stranded if unaware what is happening. This is why it’s always best, that after tuning, you reduce the closed loop and learn limits to a comfortable minimum to eliminate the chance of being stranded due to a faulty or corrupt sensor input. When used to merely trim fuel, closed loop and learn can help you optimize the EFI system for the best performance possible. EB