PPLUS Global Logistics, a freight management provider, recently released a guide outlining the proper steps for crating a performance engine for shipping. Obviously, given the expense and potential for damage to these high-value engines, shipping them requires careful attention to detail to ensure their safe transportation.

These engines are not just valuable investments, they are the heart of powerful machines that enthusiasts rely on for optimal performance. Many engine builders ship engines all over the US and the world, so to safeguard these engines during transit, it is crucial to employ proper crating techniques. Below are essential steps to effectively crate performance engines, ensuring they arrive at their destination in pristine condition.

Assessing and Planning:

Before crating a performance engine, conduct a thorough assessment to understand its unique characteristics and vulnerabilities. Consider factors such as weight, dimensions, fragility of components, and specific handling requirements. Use this information to devise a comprehensive plan that encompasses all necessary protective measures.

Cleaning and Preparation:

Before the engine is placed in the crate, ensure it is thoroughly cleaned and free from any contaminants. This step is crucial for preventing damage caused by debris or foreign particles during transportation. Additionally, inspect the engine for any pre-existing damage and document it, if any, to avoid confusion or disputes later on.

Disassembling and Securing Components:

To minimize the risk of damage during transit, disassemble the engine into its major components whenever possible. Carefully remove fragile parts such as carburetors, intake manifolds, and other accessories that could be prone to breakage. Secure each component individually and store them in padded or custom-fitted containers to prevent any contact damage.

Engine Cradle and Padding:

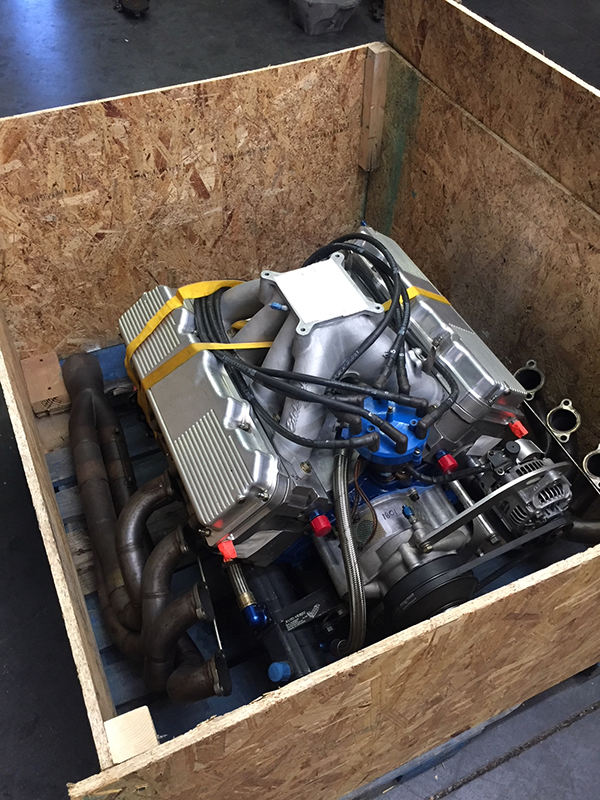

Select an appropriate engine cradle that provides a secure base for the engine during transit. The cradle should be specifically designed for the engine model and size, ensuring a snug fit. Additionally, use high-density foam padding or other cushioning materials to create a protective barrier around the engine, absorbing shocks and preventing movement within the crate.

Secure Fastening and Strapping:

Once the engine is properly placed in the cradle, ensure it is securely fastened to prevent any movement. Utilize heavy-duty straps or strong, non-abrasive ropes to secure the engine to the cradle, taking care not to overtighten and damage sensitive components. Use padding or rubber grommets to protect the engine from any potential chafing or friction caused by the straps.

Reinforced Crating and Labeling:

Choose a sturdy, high-quality crate made from durable materials such as plywood or metal to withstand the rigors of shipping. Reinforce the crate with additional bracing and corner protectors to safeguard against impacts. Clearly label the crate with “Fragile” and “This Side Up” markings, along with proper handling instructions to ensure carriers handle the package with care.

Insurance and Documentation:

To mitigate potential risks during shipping, consider obtaining comprehensive insurance coverage for the performance engine. Carefully document the condition of the engine, the crating process, and any relevant details before shipping. This documentation will serve as a reference point in case of any disputes or insurance claims.

Conclusion:

Properly crating performance engines is vital to ensure their safe transportation and protect them from potential damage. By following the steps outlined above, enthusiasts, builders, and suppliers can significantly minimize the risks associated with shipping high-value engines. Thorough assessment, careful disassembly, secure fastening, and reinforced crating are all crucial elements of a comprehensive approach to safeguarding these powerful machines during transit. By prioritizing protection, you can have peace of mind knowing that your performance engine will arrive at its destination in optimal condition, ready to deliver the power and performance you expect.