Upgrading Valve and Seat Equipment

If high quality head work is a cornerstone of your business, you should review your current situation to see if an equipment upgrade could improve not only the quality but also the quantity of your work.

The Unique Engines of ARCA

ARCA uses older style NASCAR Cup cars. Specifically, they are the ones used just before the advent of NASCAR’s Car Of Tomorrow (COT) in 2007. This means teams running ARCA can do so with a safe, well-built race car without paying top dollar.

Going Hohl School

During the 1950s and ‘60s, building and tuning a performance race engine was a different world from today. It was definitely more of a hands-on situation where the feel, sound and smell of an engine were important tools of early engine builders.

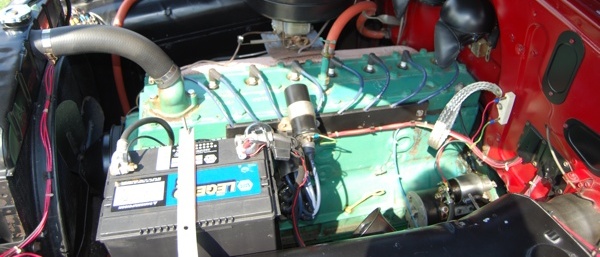

Pontiac’s Straight 8s

The Pontiac L-head straight eight was used in production cars for 21 years between 1933 and 1954. This classic engine was advertised as a powerplant that could run 100,000 miles without a major overhaul.

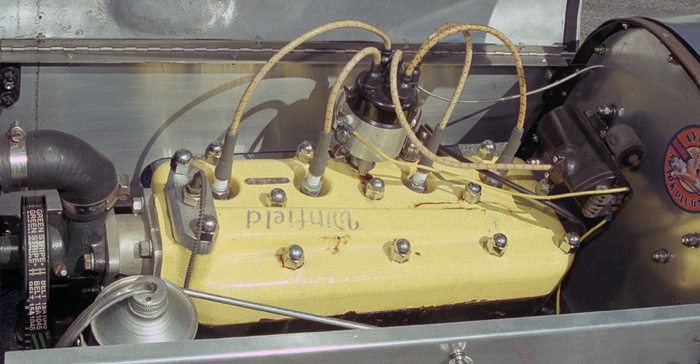

Modified Ford Model Bs

It was known as the Model B engine and was produced for only four years beginning in 1932. Sporting only four cylinders, it was basically an upgrade of the earlier Model A powerplant. The “B” engine sported an impressive 200 cubic inches of displacement. Its compression ratio was a super-low 4.9-1. The paltry 50 horses it produced came at about 2,200 RPMs. The engine certainly didn’t appear likely to be a candidate for upgrading, but that wouldn’t be the case.

Greetings From Bonneville

This year an opportunity came to go to a gathering of speed freaks drawn together from around the world. An event that I’ve now learned is on most “Motorhead’s” bucket lists, and was put forth as the background for a great movie that hit limited screens in 2005 and is recorded on DVD in many of our video libraries. The movie was “The World’s Fastest Indian,” and the event is simply called “Bonneville.”

Engine Break-In Oil and Assembly Lube Needs

Engine building is a process that should go well when everything is done correctly. A lot of things can go wrong during those first few minutes following the initial start-up of a freshly built engine. The engine has to build oil pressure quickly so all of the critical wear surfaces will receive lubrication.

The Ford ‘FE’ – Rebuilding An American Iron Icon

Ford produced the FE series engines for almost 20 years and in this time period, this series of engine gained quite a following. After researching the FE, I was intrigued about its internal workings. I had always heard about and seen some of the more popular FE engines such as the 390, 427 and 428 but never had a chance to dive into one – until now.

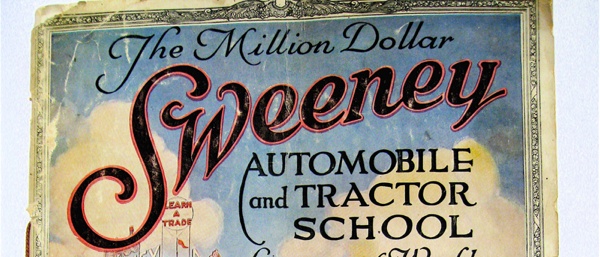

The Sweeney Automotive and Tractor School

Emory Sweeney founded the Sweeney Automobile and Tractor School, in May of 1908 in Kansas City, MO with just five students enrolled. Started on a shoestring, the enrollment fees collected from the first five students were used to rent a building and buy teaching supplies for a month.

Must Have Shop Tools & Measuring Equipment

You can’t do quality work in an automotive machine shop if you don’t have the right tools and measuring equipment. “Must have” tools and equipment include those that are necessary for engine disassembly, for inspecting and measuring engine components, and for engine assembly.

Ford’s Power Stroke Powerplants

The biggest question heard from customers is, “Why did Ford replace the 7.3L with the 6.0L?” There are good reasons as to why the 7.3L Power Stroke had to be removed from service and these reasons brought about many changes in the Power Stroke platform.

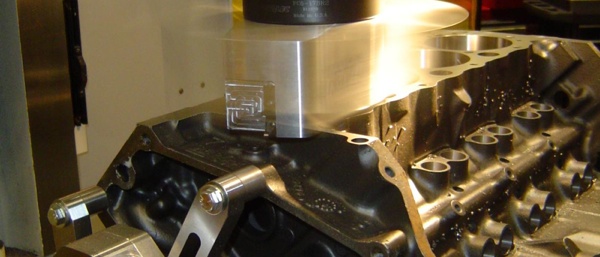

Head Surfacing and Straightening

Clean, smooth and flat have always been requirements for proper head sealing whether you are building a stock engine or a monster motor for a ProStock drag car. Head gaskets can only accommodate so much distortion and roughness across the face of the cylinder head and deck. Resurfacing the desk surface on a cylinder head and/or engine block should restore flatness and achieve the required smoothness.