Marini Diesel, Inc. Joins VIPAR Heavy Duty

Marini Diesel, Inc. has joined the VIPAR Heavy Duty network of distributor stockholders. Based in Commerce City, Colorado, Marini Diesel Inc. is a full line aftermarket distributor offering full service, engine machine shop, driveline, flywheel resurfacing, hydraulic hose and fittings and diesel particulate filter cleaning.

Dollars and Sense

How to shop for and finance equipment in today’s economy This is a question that often comes up in any shop: How can I afford new equipment? Well to answer this, first I talked to Steve Morgan, a senior relationship manager at Univest Capital, a company that specializes in equipment financing. Steve actually sold engine

IPA Flow-Thru System with Brush and Venturi

Innovative Products of America (IPA) has introduced the Flow-Thru System with Brush and Venturi (#8091), a versatile, first-time tool. It features stainless steel and abrasive nylon brush heads as well as a venturi.

You Didn’t Need a V8

What to Know When Rebuilding Ford’s Powerful 3.5L Six-Cylinder Engine Platform Originally named TwinForce, Ford had a simple and specific directive with the development of its new engine family: “Build a low-emissions vehicle, with good fuel economy, that performs so well that the driver forgets they are driving a low-emissions vehicle with good fuel economy.”

The Market For Commercial/Industrial Diesel is Thriving

Off-highway diesel engines are designed to perform in many different applications across multiple industries. These engines must be able to perform consistently and reliably in extreme conditions where there’s dust, vibration, high altitudes and generally harsh weather conditions. Such engines can be found in excavators, cranes, backhoes, forklifts and others that perform a particular job.

Norton Pneumatic Die Grinder

Norton | Saint-Gobain Abrasives, an abrasives manufacturer, has introduced its Norton Die Grinder, the latest addition to its new professional tool line. The Norton Pneumatic Die Grinder quickly and comfortably accomplishes a wide range of portable grinding applications.

Out On Open Water

Express Engines Inc. has saltwater on the brain When most engine builders think of the salt, their minds take them to the Bonneville Salt Flats and land speed records. However, if you’re Bruce Baker, owner of Express Engines Inc. in DeLand, FL, you’re thinking of saltwater, water damage and offshore racing. In fact, Baker works

When You Can’t Buy It, Building It Expands Your Shop Capabilities.

We all get crazy ideas from time to time. Sometimes we see something and that sparks an idea. Other times we’ll have a need and, “necessity being the mother of invention,” we come up with an idea of how to build that special part or tool that would fix the problem. The majority of the

Solutions for Common Corrosion Issues

A finishing method that removes the surface metal and its contaminants is the solution to premature corrosion. There are a number of finishing methods available, and each has its pros and cons.

How to Create Dollar Bills Out of Four Common Materials

From engine blocks and heads to oil pans and intake manifolds – engine components are common items that require repair, maintenance or replacement in the shop. Whether you’re working on a car, light-duty truck, heavy-duty diesel or a performance racing vehicle, you may frequently encounter a cracked block or cylinder head that requires a welding

Third-World Problems, First-World Production

Ask the typical reader of Engine Builder what his biggest business challenge is and you might hear complaints such as bargain basement internet parts sales, competition from OEMs and an inability to find enthusiastic employees. Ask Andrew Yorke about his headaches and things sound a bit different. “Things that all my fellow engineers take for

How to Break-In Your Piston Rings, The Right Way!

Captain Kirk in the now-classic Star Trek TV series was constantly badgering poor Scotty for “More power!” That’s what everybody wants. More power! One way to ensure the horsepower built into your engine is achieved is to seize every opportunity to seal that cylinder pressure on the push side of the pistons.

Shop Solutions – April 2017

Exhaust manifolds can be resurfaced using a surface grinder with the typical universal cylinder head fixture. First start by tapping threads in the thru holes.

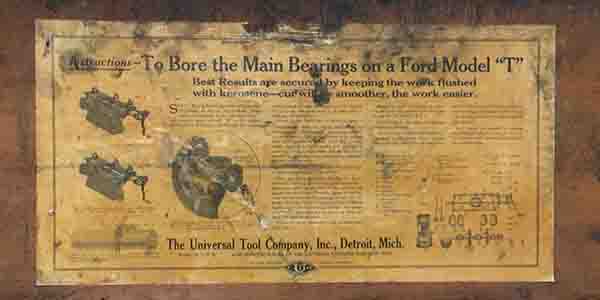

How Did We Get Here?

Today, I am going to take you on a journey back in time to see what started this whole industry of rebuilding engines and what events made us who we are for what we do today.

Shop Solutions – December 2017

It can be much easier to install and remove spark plugs, when space is tight due to header configuration by notching out one section of a spark plug socket. This will allow for a better angle, and you can still use the hex head rather than a ratchet drive.

Why Cutting Fluids Are Imperative to Machining

In order to produce the best performing engines with tight tolerances and finishes, CNC machines require cutting fluids to perform at the highest levels. You might think a fluid is a fluid is a fluid, but you’d be wrong.

September 2017 Shop Solutions

In our shop we seem to constantly be moving cylinder heads around. First, from arrival at the door to a tear down bench, then to the jet wash, to a storage shelf, to benches to be worked on and then to benches to be assembled. To do it all efficiently, we have three 34” tall 4-wheel carts.

AMSOIL Showcases New Products at SEMA

AMSOIL has launched 13 new products since SEMA 2016 and will be on display in the SEMA New Product Showcase and in the AMSOIL Booth #24859 located in Central Hall.

Core Sourcing Heads & Blocks

Cores are the heart and soul of the engine rebuilding business. If you don’t have a core, you don’t have an engine to rebuild. The challenge is getting the right cores that are in demand, and at a price that you and your customers can afford.

Solving Gasoline Direct Injection Issues: The facts and fictions of GDI

Gasoline Direct Injection or GDI has seen rapid adoption by the automotive industry over the last several years in lieu of multipoint fuel injection systems due to advantages in fuel efficiency and reduced emission levels.