Diesel Cranks and Connecting Rods

The demand for mid-size diesel performance products continues to grow. There tends to be two sides of the mid-size diesel spectrum: on one side there is street performance and on the other there is all-out race. Street performance diesels deal mainly with engine parts that are primarily for bolt-on applications and can make great power

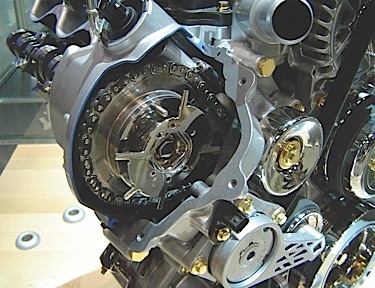

Service Issues on Ford 4.6L SOHC & DOHC Engines

In 2005, Ford introduced a three-valve (3V) SOHC version of the 4.6L for the newly restyled retro-look Mustang. Major changes included the use of two intake valves and one exhaust valve per cylinder to increase air velocity, torque and power, variable cam timing and a weight-saving aluminum cylinder block. Ford’s overhead cam 4.6L V8 engine has been

Diagnosing Engine Noise Under The Hood Of A Ford F-150

This article is about diagnosing a mysterious engine noise in a 1989 Ford F-150 pickup equipped with the venerable 5.0L or 302 cubic-inch V8 engine following a rebuild. Most of us working in the automotive service trades are very familiar with Murphy’s Law and how it affects our shop’s cost of doing business. Murphy’s Law

Engine Builder Shop Solutions: July 2013

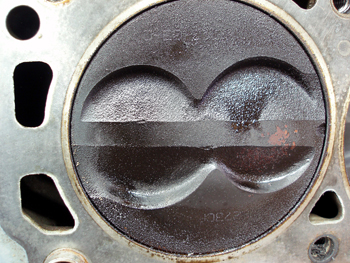

How to See Through Pistons for Clearance With the advent of longer stroke crankshafts, one inch plus lift camshafts, raised camshaft locations, lifter angles, bore spacing, etc., exact camshaft lobe and connecting rod clearance may not be able to be determined from looking up from the crankcase area of the block. To see through the

One Minute Might Save You Thirty!

The call, one of hundreds made every day, goes something like this: “Hello. This is Billy-Joe-Bob, can I help you?” “Yeah Billy, this is Hank with Smith Machine. I’m working on an F-150 with a 4.6 and I need some parts.” “OK, Hank. I have several Smith Machines, do you know your account number?” “No.”

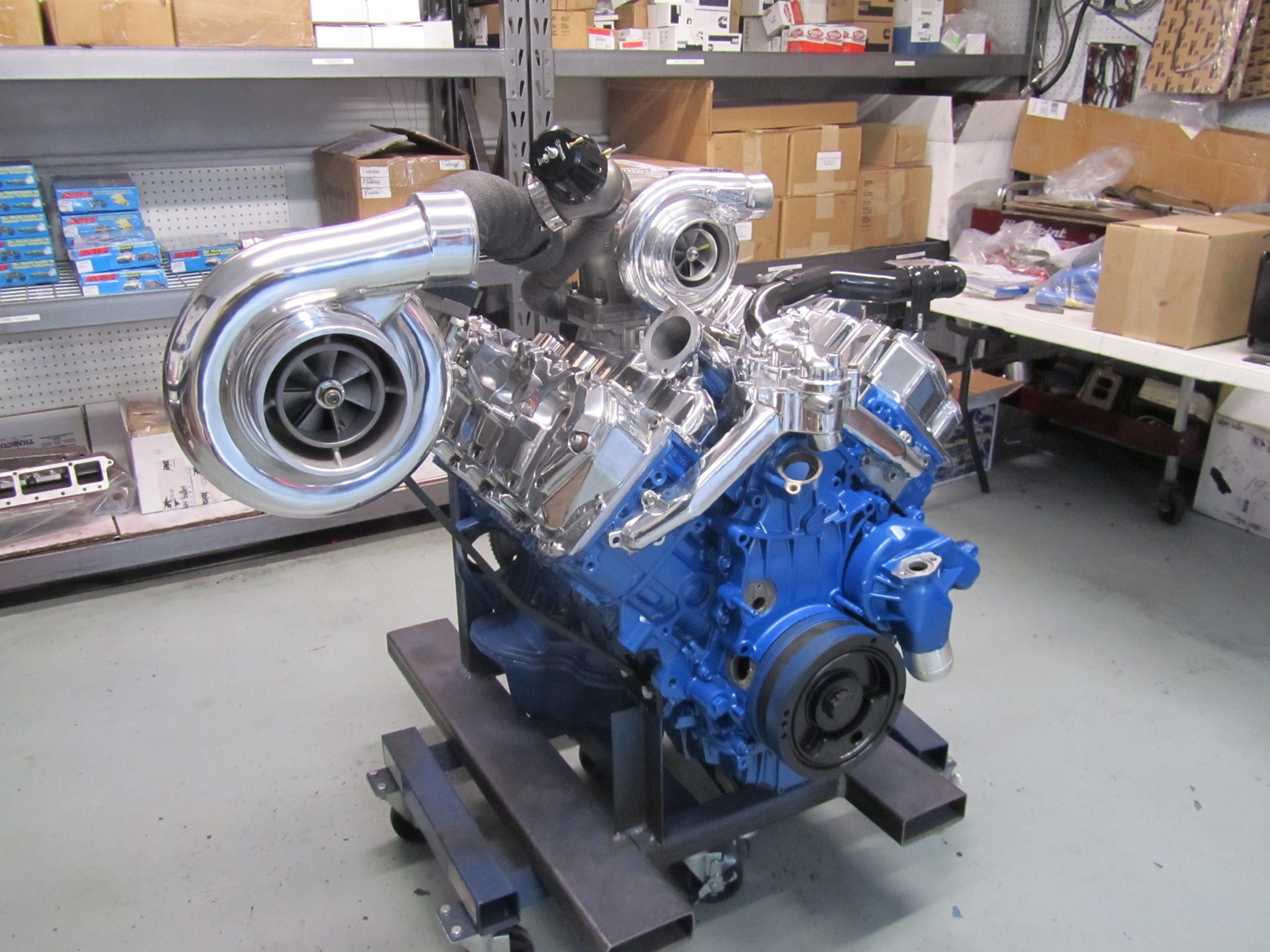

Performance Diesel: The New Hot Rods

With all of the bolt-on diesel components that are available on the market these days, why would you get into offering performance engine rebuilds for the diesel market? I’m sure you are asking yourself this question every time you get a call from someone with a diesel engine asking how they can get more power. But believe

2013 Machine Shop Market Profile Part 1

Since that time, a lot of things have changed at this magazine and in this industry. What hasn’t changed is the fact that we have consistently surveyed the same machine shop/custom engine rebuilder (CER) population to get a snapshot of this industry from the experts – you, the engine rebuilder. Numbers can give a cold,

Parts Making With Your CNC

Computer Numeric Controlled (CNC) machining allows engine builders to achieve almost unbelievable levels of accuracy and consistency. The programmability of a digital computer not only automates the operation of the equipment but also provides a level of repeatability that can’t be matched by manual equipment. That’s why CNC has been the backbone of virtually all

Pursuing The Small Engine Market

Small engines are everywhere. They power lawn mowers, garden tillers, portable generators, all kinds of pumps, go-carts, ATVs, snowmobiles, motorcycles, forklifts, even refrigerated trailers on reefer trucks. Most of these engines are single-cylinder four-stroke air-cooled motors that range in power from 5 to 15 hp or more. Some have vertical crankshafts and some have horizontal

Going Green Not Just for Irish

Did you know that as engine builders, we were green long before green became the IN thing? We were green even before Kermit said it wasn’t easy. How are we green, you ask? We are green because we rebuild, which means we recycle. Green is defined as: • Relating to or being an environmentalist

Bearing Clearances

Is it better to build an engine with tighter bearing clearances and run it on low viscosity synthetic motor oil, or is it better to build an engine with more traditional or even looser bearing clearances and use heavier viscosity oil? Tight bearing clearances and relatively thin synthetic multi-viscosity motor oils work well in many

Rebuilding Chrysler’s ‘Revived’ Engine Family

Casting numbers, VIN codes, components and processes to rebuild/remanufacture these engines are compiled for Chrysler’s newly revised engine family including 4 cylinders, V6s and V8s Chrysler made some major changes in their engine line-up starting in ’07. They replaced their four cylinder engines in everything but the PT Cruiser in ’07, updated the 4.7L V8

The Raptor Takes Flight

In an age when kids would rather hot rod their computers than their cars, it’s kind of amazing that old fashioned hot rodding still exists – even thrives in today’s society. While computers certainly have their place, the younger generation is still looking for entertainment and thrills – whether captured in HD?or in real life.

Restoration Engine Market Update

The resto market can be a good source of extra business or a solid specialization option You might joke that the restoration engine marketplace is a “dependable” business niche. Trying to get a handle on its size, shape and character depends on with whom you talk and what they consider a vintage car to be.

Solving The Riddle Of The V10 Chrysler Cylinder Head

I know, I know – don’t quit my day job. But that really IS my dayjob – dealing with mysteries and riddles. In this case, the riddle isthe cylinder heads of the 8.0L, V10 Chrysler truck engine. Although there aren’t nearly as many of the Chrysler V10 engines out inthe marketplace as the Ford Triton

Crank It Up

Whether you think diesel crankshafts are the same as or different from their smaller gasoline counterparts, you’re right. Diesel crankshafts and rotating assemblies – like their cousins in the gas engine world – turn a linear motion from combustion into a rotating motion that can move a vehicle, supply power through a generator, pump oil

Crack Detection and Correction

First off, let’s get one thing perfectly clear – there’s no such thing as “flawless.” Like those shocking tabloid photos of that Hollywood actress who gets blindsided beside a bistro, even the most conscientious engine builder sometimes has to deal with surprising surface imperfections. And just as she has paparazzi to expose the damage and

Getting Your Bearings

Engine bearings have a tough job to do for such a small component. They must support big loads on a thin film of oil (between .0001-.0004? thick) between themselves and the crankshaft journals to prevent metal-to-metal contact. One of the biggest causes of bearing failures is dirt and debris that enters into the oil pan

Removing Crankshaft Pilot Bearings Revisited (#4)

When removing a crankshaft pilot bearing, the easiest way is to use modeling clay or Play-Doh. Pack the clay into the hole first by hand, and then hammer it in with a tight fitting bolt or blunt chisel. It doesn’t take much force to make the bearing pop out. There is no mess, and the

Debunking the 10 X 10 Crankshaft Myth for Customers (#5)

First of all, in normal use or even high performance use, a used crankshaft will not “clean up” to standard specifications and will usually have to be ground to .010? undersize. The crankshaft has then remained 98+ percent as strong as new. The problem arises when “spinning” or “hammering” (knocking) a bearing. The crank will