In 2005, Ford introduced a three-valve (3V) SOHC version of the 4.6L for the newly restyled retro-look Mustang. Major changes included the use of two intake valves and one exhaust valve per cylinder to increase air velocity, torque and power, variable cam timing and a weight-saving aluminum cylinder block.

Ford’s overhead cam 4.6L V8 engine has been in production since 1991 and has been used in a wide variety of Ford, Lincoln and Mercury models from Crown Victorias and Mustangs to F-150s and Expeditions.

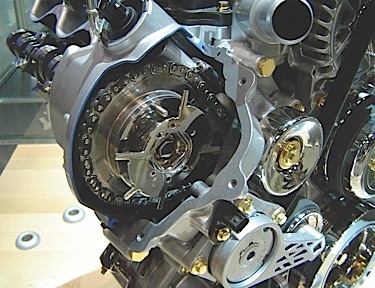

There are millions of these engines on the road and there are a lot of different versions of the engine including two-valve and three-valve single overhead cam (SOHC) engines, and four-valve dual overhead cam (DOHC) engines.

The two-valve (2V) 4.6L was the first production version, built in two different Ford plants (Romeo and Windsor).

For some reason known only to Ford’s engineers, the Romeo and Windsor engines were not |identical, which means you have to know which engine you have if you are rebuilding it or replacing internal parts.

The engine blocks are slightly different, the cams and cam gears are different, the crankshafts are different, and the heads and valve covers are different.

For example, Ford began producing the Triton overhead camshaft (OHC) engine in 1997 in V8 and V10 configurations, which was installed exclusively in its trucks and SUVs (not cars).

Over the years, there have been numerous variants, changes and improvements in the 4.6L V8. In 1999, 2V engines destined for Mustangs got a Performance Improved (PI) package that included revised square port Windsor heads and deeper dished pistons. The Romeo plant added the PI square port heads in 2001.

The “Not Power Improved” (NPI) oval port heads also remained in production through 2000 in the Romeo plant. There were also variations in camshafts, front timing covers, cam drives and timing chain guides used in the 2V engines.

[inpost_gallery post_id=4898 group=”1″ sc_id=”sc1492621272961″]

In 1993, a four-valves-per-cylinder (4V) high output version of the 4.6L V8 with dual overhead cams and an aluminum block was produced for the Lincoln Mark VIII. In 1999, the head ports on the 4V engine were revised for better airflow, and in 2003-’04 a special four-bolt main cast iron block was produced exclusively for the Mustang SVT Cobra. The 4V engine continued in production through 2004 in the Mustang.

In 2005, Ford introduced a three-valve (3V) SOHC version of the 4.6L for the newly restyled retro-look Mustang. Major changes included the use of two intake valves and one exhaust valve per cylinder to increase air velocity, torque and power, variable cam timing and a weight-saving aluminum cylinder block.

The improvements bumped the power output up to 300 hp (compared to 190 to 250 hp for the older 2V 4.6L V8s).

All of these 4.6L engines are often referred to as Ford “modular” V8s. The implication is that the engines share a lot in common and that parts are interchangeable.

Nothing could be further from the truth. The word “modular” only means that the tooling Ford uses on its production lines is modularized (standardized) so that it can be used to produce engines with similar configurations and geometry.

It does not mean Ford designed the engines so there would be a lot of parts commonality between all the 4.6L engine variants.

Service Issues

Like any engine family, there have been a number of service issues with the 4.6L engines over the years:

One of the major issues has been that of changing the spark plugs on 2005 to early 2008 Mustangs, 2006 to early 2008 Explorer and Mountaineer, and 2007 to early 2008 Explorer Sport Trac with the 4.6L V8.

On engines built prior to Nov. 30, 2007, Ford used a two-piece spark plug that has a long steel tubular ground electrode around the center electrode. This is necessary because the plug extends deep into the cylinder head so it can be positioned near the center of the combustion chamber.

When you attempt to remove the spark plug, corrosion on the outer portion of the ground electrode and carbon buildup between the plug and head can bind the plug. If you are not extremely careful while loosening the plug, you can easily break off the outer ground electrode where it joins the upper part of the spark plug.

The busted metal tip of the spark plug and center electrode remain in the head when the top of the plug comes out. This same problem also afflicts 5.4L V8 truck engines from 2004 to early 2008 because they use the same type of spark plug.