Shop Solutions October 2015

Managing your scrap is an everyday chore. We all know aluminum pistons are worth more than aluminum mill waste, but by removing pins and rings they’re worth even more.

Connecting Rods

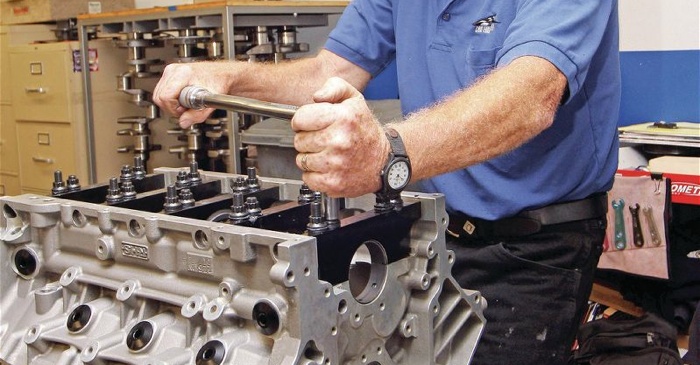

They say an engine is only as reliable as its weakest link. The connecting rods that join the pistons with the crank can be a strong link or a weak link depending on the rods that are used.

Sourcing Engine Blocks

Production engine builders today want engine cores that match a very specific vehicle application. In many cases, they also want the tinware that goes with the engine because the oil pan, valve covers and timing cover are also year, make and model specific. That has changed the way core suppliers have to inventory their stock.

Toyota Looks to Overhaul its Engines

After ignoring the internal combustion engine in favor of its hybrid car models, Toyota Motor Corp. is preparing a powertrain makeover. The automaker is designing common parts to spread costs across large numbers of engines. This will allow it to economically customize engines for specific vehicles with fuel injection, turbocharging and more.

Shop Solutions August 2015

I found myself without a welder to use to remove a check ball staked into the end of an oil passage of a crankshaft. So I applied a different technique to remove it to clean the crank.

Machine Shop Market Profile

As we move through our 51st year of covering this industry, the staff of Engine Builder recognizes that old adage – the more things change, the more they stay the same. What’s changed about this industry is, well, pretty much everything. What’s stayed the same is the dedication and hardwork of the professionals who keep engines running and customers happy.

Allison Power

In December, we discussed the use of Allison engines – originally designed for use in WWII fighter planes – in watercraft applications. Now, we’ll pick up the story of these versatile powerplants finding success on dry land.

Parts Coatings

Whether it’s more horsepower, better throttle response, or better durability, everybody is looking for an edge when it comes to building a performance engine. Any of these can win races. So what kinds of tricks are winning engine builders using to get an edge over their competitors? Many are using highly specialized coatings.

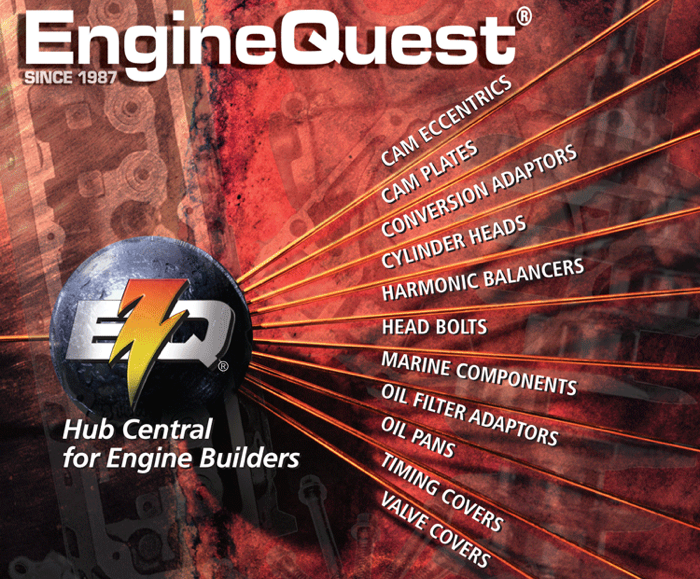

EngineQuest 2015 Parts Catalog

EngineQuest’s 2015 parts catalog is packed with new and hard-to-find parts for many domestic and foreign applications and also contains detailed product specifications that will help you select the right part for the powertrain you’re working on.

Forced Induction Facts

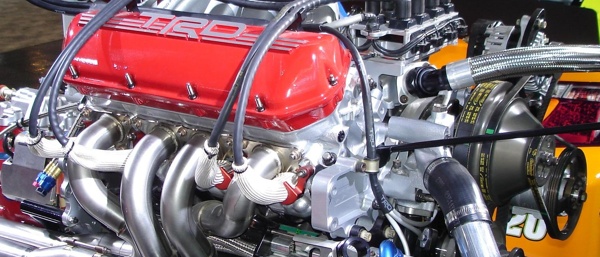

Many articles outline the guidelines and basic knowledge to follow when installing some form of a forced induction system. Sometimes you’ll see the “quick and easy way” to upgrade an existing forced induction system, like a turbo, supercharger and/or nitrous oxide system. What if your customer wanted a bigger turbo for a diesel engine or decided to change the pulley size of the supercharger, or maybe use a bigger shot of nitrous on a street car?

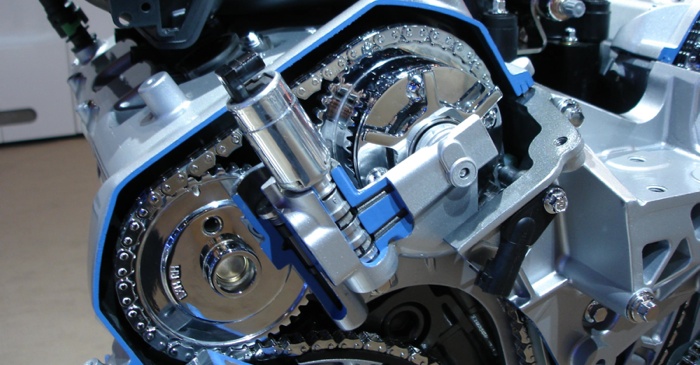

Timing Components

For metal parts to rotate, move, lift, bend, sway and – hopefully – not touch multiple times per second, every minute of every hour the engine is running takes more than just good enough – it takes precision that Swiss railroad conductors would envy. While everything in the engine has to precisely fit and accuracy is key, nowhere is precision more critical than in the timing.

Wisconsin Winners

NVR is a race-oriented engine shop that builds mostly circle track and drag vehicle engines. With more than 40 years in the industry, Tom Nickerson works with his wife Cindy handling mostly Chevrolet builds, as well as other nameplate engines. NVR was named the 2014 Performance Engine Builder of the Year and we took a look at its operation.

Understanding Today’s Bearing Clearance Recipe

What’s needed to keep the rotating assembly rotating? It’s a recipe that includes three key ingredients: the bearing, the crankshaft and the oil. But understanding the part each plays as part of this recipe is what’s needed to keep your engines’ bearings from failing.

SCAT 77 Series Big Block Post Small Block Chevy Forged Crankshaft

SCAT Crankshafts has a new player in the family. The new 77 Series Big Block Post, Small Block Chevy 4340 Forged crankshaft is ideal for Blower, or Dry-sump pulley applications.

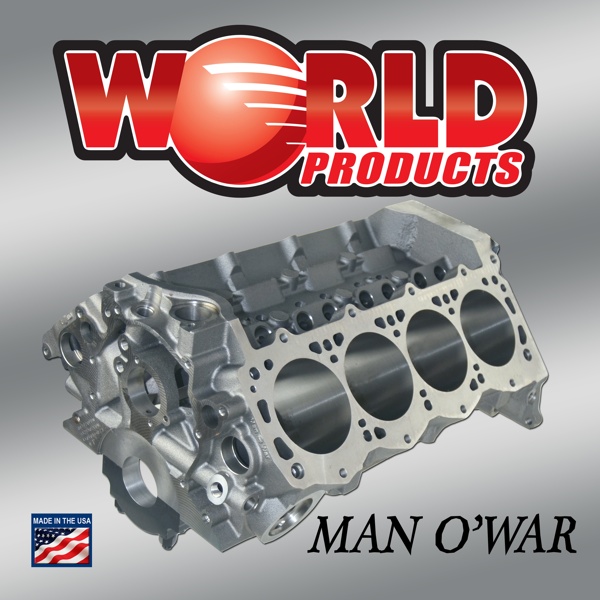

World Products Windsor Style Small Block

World Products has revised its small block Ford castings to make the blocks even stronger and easier to build. Available with a 302 style 8.200″ deck height or a Windsor style 9.500″ deck height, the Man O’War blocks are packed with performance enhancing features such as higher grade iron alloy for even greater strength. See World Products at PRI in booth #1343.

Behind the Scenes Look at Scat Crankshaft Manufacturing

With over 50 years of manufacturing experience, SCAT Crankshafts proudly produces some of the finest crankshafts in the world. With thousands of race proven wins, SCAT ensures customers receive the highest quality components on the market. In addition, SCAT rods are made from a two-piece chromoly steel forging to ensure maximum strength and durability for small and big block Chevy, Ford, Chrysler, Pontiac, Honda and many more. Visit SCAT at PRI in booth #2125.

Performance Oiling Systems

The basic purpose of an oiling system is to provide lubrication for the engine. It doesn’t matter if the system is a wet sump with an internal oil pump mounted in the crankcase or front cover, or a dry sump system with an external multi-stage pump. The engine doesn’t know the difference as far as where the oil comes from – as long as the flow keeps coming at all RPMs and under all operating conditions.

Parts Happen

We chose to expand on the idea of taking the engine under the hood of your customer’s car, and modifying it rather than searching out a more desirable muscle car engine. Now, with the money you’d save by not having to purchase another expensive desirable core motor, invest that money into a stroker crankshaft and a set of matching pistons to build a bigger cubic inch engine that would have more power than the old factory muscle car engine and greater dependability from the new upgraded parts.

Company Innovations

While technology in general was the primary answer to what innovations helped grow the industry over the past 50 years, when asked about innovations within their own companies that have helped the industry, the answers were more specific to certain engine parts. “Over the years a number of Sunnen innovations have been standards of the

SCAT Enterprises

In 1966, SCAT founder, Tom Lieb, saw there was an opportunity making crankshafts. Demand quickly exceeded supply. SCAT invested in equipment and developed a supply line for cores. The rest is history. In 1972, SCAT looked at rod manufacturing and took on that challenge as well.