Parts Coatings

Whether it’s more horsepower, better throttle response, or better durability, everybody is looking for an edge when it comes to building a performance engine. Any of these can win races. So what kinds of tricks are winning engine builders using to get an edge over their competitors? Many are using highly specialized coatings.

Melling Performance Shark Oil Pumps

Melling has improved the heart-beat of the traditional internal gear pump. It is now significantly smoother through the use of new helical asymmetrical gears. The new gear design provides the engine with an improved flow of oil without the usual pulsing found in traditional gear pumps.

How Not to Lose the Race to the Bottom

You know how it feels when you explain something over and over and the person just doesn’t seem to get it? Some seven years ago I broke into the pages of Engine Builder with an article about dealing with what I called walk-in parts. Off and on again I’ve gotten back on that bandwagon because the topic just keeps getting more and more relevant.

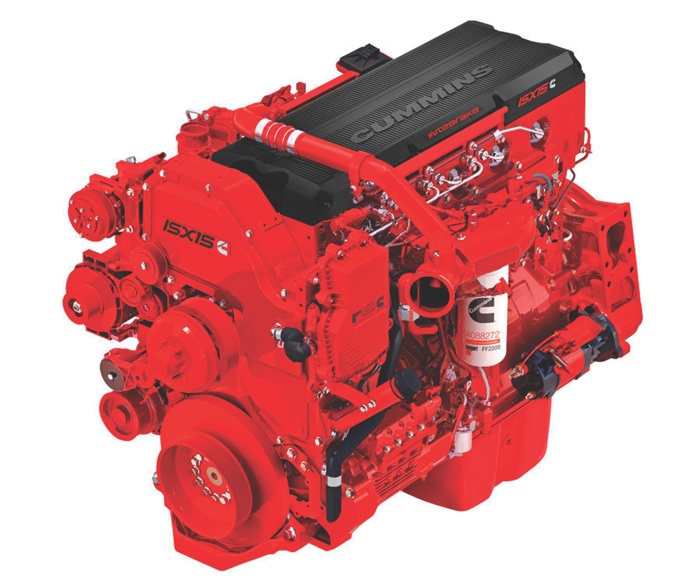

Why Diesels Have Become ‘Greener’ and How You Can Benefit

For several years now, clean air and better fuel economy have been the primary focus of the transportation industry. Back in the 1970s, the clean air agenda came into full swing and it literally crippled performance as well as reliability. At that time, the diesel industry wasn’t being regulated by any of these emissions standards, but changes were on the horizon.

Shop Solutions April 2015

Hydraulic valve lifters are probably the most precision-machined part inside any engine. It does not take much to cause one to operate incorrectly. Here are some tips for fixing this problem, as well as some other helpful solutions to commonly seen shop scenarios.

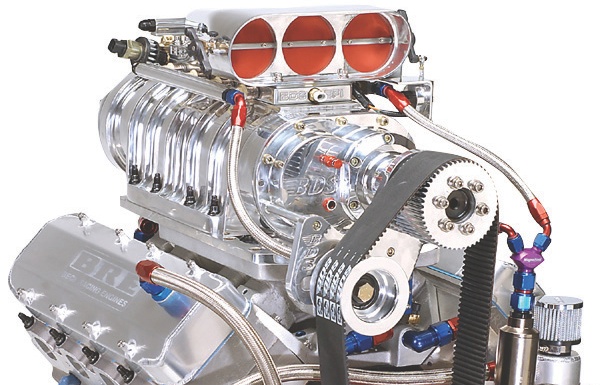

Forced Induction Facts

Many articles outline the guidelines and basic knowledge to follow when installing some form of a forced induction system. Sometimes you’ll see the “quick and easy way” to upgrade an existing forced induction system, like a turbo, supercharger and/or nitrous oxide system. What if your customer wanted a bigger turbo for a diesel engine or decided to change the pulley size of the supercharger, or maybe use a bigger shot of nitrous on a street car?

More Power Inside – Muscle Cars

There are many aspects of the famous and desired muscle car engines of the 1960s and ‘70s. They have become the holy grail of factory performance engines, but they are getting more and more scarce as the years go by. For car owners, the engines have evolved in recent years into three different configurations. Read on to learn more.

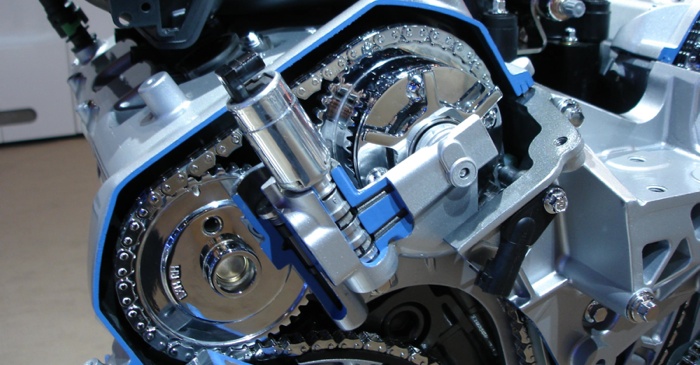

Timing Components

For metal parts to rotate, move, lift, bend, sway and – hopefully – not touch multiple times per second, every minute of every hour the engine is running takes more than just good enough – it takes precision that Swiss railroad conductors would envy. While everything in the engine has to precisely fit and accuracy is key, nowhere is precision more critical than in the timing.

Tuning Forced Induction Engines

Tuning a forced induction engine on a dyno can be a daunting task. Trying to tune an engine that will make lots of boost and a ton of power can be even more challenging. These engines tend to make so much power when they come on to the boost that they often will rip right through the RPM ranges you are trying to tune. This can be very frustrating to a novice tuner. Here’s something that may help.

The Challenges and Opportunities of Variable Valve Timing

Variable Valve Timing (VVT) has been incorporated into many late model import and domestic engines, including single overhead cam (SOHC), dual overhead cam (DOHC) and even pushrod V8s such as GM’s GEN IV 5.3L and 6.0L engines. It is a technology that offers performance, emissions and fuel economy advantages for everyday driving, but it also creates some challenges for engine builders.

New Engines Force New Pistons

As engines get smaller, motorists expect the same performance as a larger V6 or V8 but with the fuel economy of a four cylinder. Turbocharging makes little engines breathe big, but it also increases the load and temperature the pistons have to endure. This, in turn, requires pistons made of alloys that can withstand higher temperatures and combustion pressures. Yesterday’s castings won’t cut it for these kinds of applications.

Knowledge is Power

What does a guy or gal do when the next unfamiliar job walks in the front door? Where does one go for technical information about the really old or the recently designed engine job you’ve just been presented with? Read on to find out.

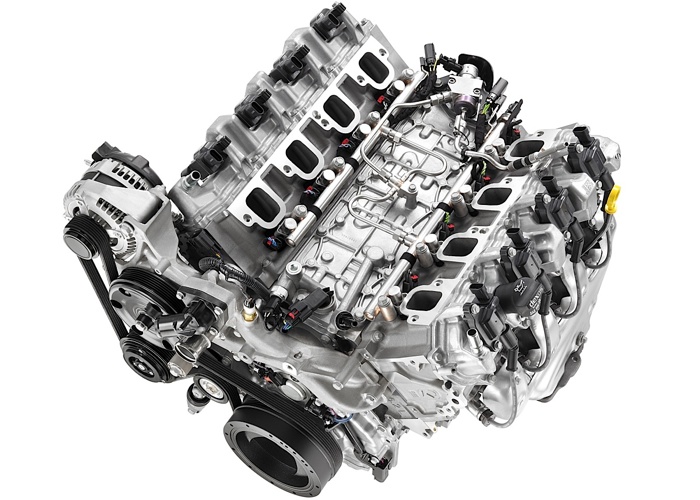

Understanding the LT1’s New Direct Injection

The LT1 now features direct injection, AFM (Active Fuel Management), continuous variable valve timing, and a new combustion system that incorporates 11.5:1 compression ratio. The LT1 combustion system is the most intensely analyzed, developed and optimized system in GM history.

Edelbrock’s 60th Anniversary Small-Block Sweepstakes

Now’s your chance to enter to win a unique engine commemorating the 60th Anniversary launch of the small-block Chevrolet engine. One lucky winner will receive a small-block Chevrolet 350 with Edelbrock top end components including an Enforcer Supercharger system built by the Engine Tech team at PowerNation.

Easy-Run Engine Test Stands

Easy-Run Engine Test Stands are a solution for starting and testing engines before they are installed in a vehicle. Easily test new, used or rebuilt engines, detect leaks, tune, and properly break in camshafts. With the high expense of labor and paint cost, you can detect engine problems before installation in the vehicle, thereby avoiding the potential need to remove and reinstall the engine.

Direct Injection Engines and Carbon Deposits

When the early direct-injection engines hit the three-year or 30,000-mile mark, some developed driveablity problems due to carbon buildup on the necks of the intake valves. In the late ‘90s and early 2000s, TSBs related to carbon deposits on the valves were few and far between. There are three reasons why direct-injection engines are more prone to carbon deposits. Read on to find out.

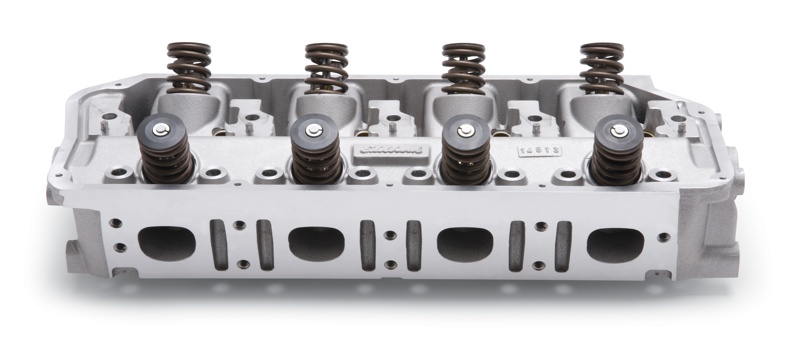

Edelbrock Victor Jr. CNC Cylinder Heads for HEMI Engines

Edelbrock’s new Victor Jr. CNC cylinder heads are designed for high output 650+ hp Chrysler 426-572 HEMI engines. They feature fully CNC machined 170cc combustion chambers and seats CNC blended into cast ports for optimal performance. They also feature a 245cc intake runner volume and a revised exhaust valve angle to accommodate larger intake valves.

Racing Engine Rule Issues for 2015

As a performance engine builder for customers driving in various racing associations, keeping up with rules changes from the numerous organizations can be a challenge. Josh Tennis, head technician at GPM Race Engines in Eagle Rock, MO, and one of Engine Builder magazine’s new advisory board members, said speaking from his experience, it’s up to the shop to investigate engine-related rule updates.

Melling Releases Five New Part Numbers

Melling, a leading manufacturer of oil pumps and other power train components, has announced five new part numbers. Melling has introduced variable cam timing housing, variable cam timing solenoid, camshaft sprocket actuators and rocker arms.

Engine Builder’s Chrysler 392 Magnum V8 Engine on ebay

Engine Builder magazine’s Chrysler 392 Magnum V8 engine will be back up for auction on eBay Motors in 2015. This Chrysler 318 turned 392 Magnum produces 477 HP at 5800 RPM and 481 lb. feet of torque. The auction is running right now and will be open to anyone in the U.S. Proceeds will benefit the Independence Fund.