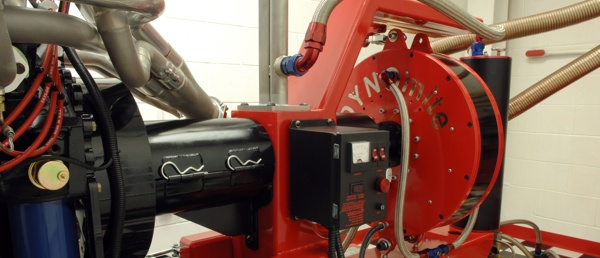

Consider a Dyno/Flow Bench for Your Shop

Any engine builder that is doing performance work or high volume engine building can benefit from owning an engine dynamometer. A dyno is not just a tool for plotting horsepower and torque curves. It’s also a tuning tool for plotting and adjusting fuel mixture and ignition calibration, a quality control tool to assure proper engine break-in, valvetrain adjustments and to verify compression, ring seating and gasket sealing. It can also be used as a performance and/or durability research tool.

Selecting Pushrods, Rockers and Springs for Your Build

Everybody knows you need the right combination of valvetrain components to maximize an engine’s power potential. The trick is figuring out which components are the “right” ones for a given application. A high revving engine with an aggressive cam needs lightweight rocker arms and stiffer valve springs to keep up with the cam.

Five Points to Ponder Prior to PRI

Being an FE Ford fan, and having raced them, and still owning several, “Animal” Jim enjoyed Engine Builder’s article about FE Fords in the April Issue. Jim has been in love with FE’s since his brand new ’63 R code he had when he was 22. In this article he share’s five points prior to the 2014 PRI show.

Elgin Announces New Pro-Stock Performance Catalog

A comprehensive new catalog featuring the dramatically expanded Elgin Pro-Stock line of performance components for street, racing, marine and other applications will be available at next week’s Performance Racing Industry trade show in Indianapolis. The catalog will be distributed at the Elgin Industries booth (No. 5032) in conjunction with the company’s 95th Anniversary celebration.

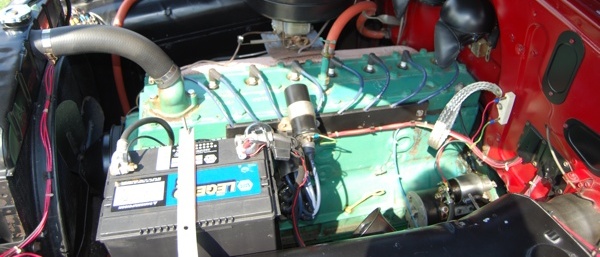

Pontiac’s Straight 8s

The Pontiac L-head straight eight was used in production cars for 21 years between 1933 and 1954. This classic engine was advertised as a powerplant that could run 100,000 miles without a major overhaul.

Company Innovations

While technology in general was the primary answer to what innovations helped grow the industry over the past 50 years, when asked about innovations within their own companies that have helped the industry, the answers were more specific to certain engine parts. “Over the years a number of Sunnen innovations have been standards of the

Melling / Dura-Bond

The Melling story began in 1946 in Jackson, MI, when George Melling Sr. and his son Ben started production of aftermarket oil pumps. In 1952 they introduced the first high-volume oil pump, which revolutionized the automotive aftermarket industry for oil pumps. In 1975, Harry Melling took over the company as the third generation president. Harry’s

Engine Builder 50th Anniversary

The next time you’re on a TV game show or playing trivia with friends, and the question is, “What is the most significant month in the history of the transportation industry?” let me suggest that you answer, “October 1964.” May I present the evidence for my argument? October 1, 1964: The world’s first high-speed rail

Engine Break-In Oil and Assembly Lube Needs

Engine building is a process that should go well when everything is done correctly. A lot of things can go wrong during those first few minutes following the initial start-up of a freshly built engine. The engine has to build oil pressure quickly so all of the critical wear surfaces will receive lubrication.

The Ford ‘FE’ – Rebuilding An American Iron Icon

Ford produced the FE series engines for almost 20 years and in this time period, this series of engine gained quite a following. After researching the FE, I was intrigued about its internal workings. I had always heard about and seen some of the more popular FE engines such as the 390, 427 and 428 but never had a chance to dive into one – until now.

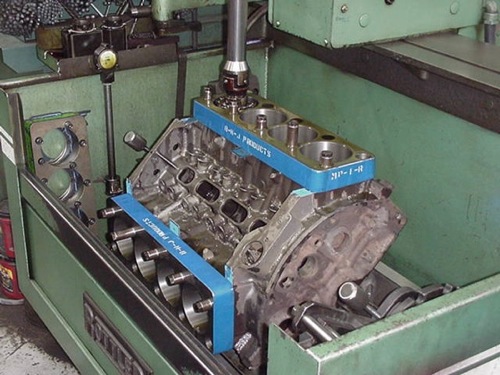

Must Have Shop Tools & Measuring Equipment

You can’t do quality work in an automotive machine shop if you don’t have the right tools and measuring equipment. “Must have” tools and equipment include those that are necessary for engine disassembly, for inspecting and measuring engine components, and for engine assembly.

Ford’s Power Stroke Powerplants

The biggest question heard from customers is, “Why did Ford replace the 7.3L with the 6.0L?” There are good reasons as to why the 7.3L Power Stroke had to be removed from service and these reasons brought about many changes in the Power Stroke platform.

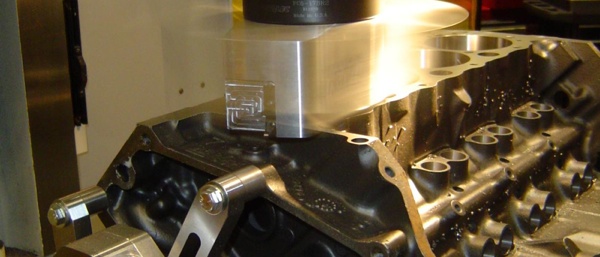

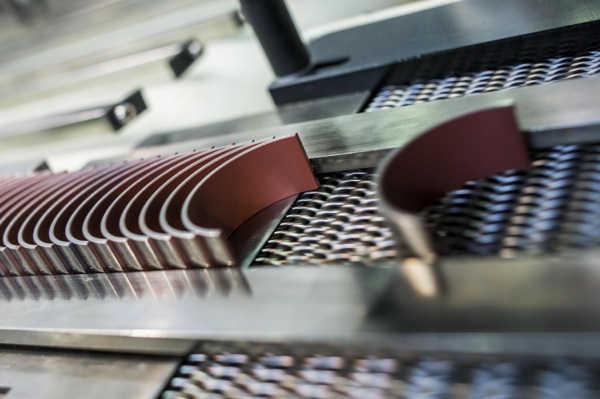

Head Surfacing and Straightening

Clean, smooth and flat have always been requirements for proper head sealing whether you are building a stock engine or a monster motor for a ProStock drag car. Head gaskets can only accommodate so much distortion and roughness across the face of the cylinder head and deck. Resurfacing the desk surface on a cylinder head and/or engine block should restore flatness and achieve the required smoothness.

K1 Crankshafts and Connecting Rods for GM LS Engines

Forged from 4340, the tough, shock and impact resistant alloy steel, K1 Technologies has introduced a new range of high-performance crankshafts and H-beam connecting rods for racing and high performance LS engines.

Racing with the Ramchargers

Before Neil Newman’s tenure with Chrysler Marine Division, he had gone to school at the Chrysler Engineering Institute (CEI) with many members of the original, legendary “Ramchargers” drag racing team.

Breaking Rules With Our 392 Magnum Engine Build

Breaking Some Rules — that’s what we’ve been doing and promoting with our 392 Magnum engine build. And with our plans to raffle the finished product and raise money and awareness for the work being done by the Independence Fund (www.indepencefund.org ) for our disabled veterans, we’re really doing something different, at least for us.

The Evolution of Surface Treatments

In the never ending quest for better performance, durability and reliability, various types of surface coatings and treatments have evolved as solutions for problems that have vexed engine builders for years. Coatings that were once considered exotic race-only solutions are now being used on a wide variety of stock and performance applications. If you’re not

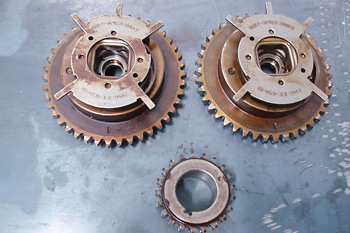

Variable Valve Timing Theory and Principles

There’s no doubt that engine specialists will begin seeing more variable valve timing (VVT) designed engines in their shops, as the generation of vehicles equipped with this technology begins to make its way into the service industry. In fact, the current versions of VVT were popularly introduced into domestic production about 10 years ago. Operating

Thank You Notes: 392 Magnum Engine Charity Build Update

As we get closer to completion of Engine Builder magazine’s 392 Magnum Charity Engine Build project, we would like to take a moment and update the project status and thank all those responsible for this project. First of all, we would like to thank Dave Sutton, contributing editor for Engine Builder for organizing this

Shop Solutions August 2014

Cleaning Bucket Style Hydraulic Lifters Unlike their flat tappet cousins, bucket style hydraulic lifters can often be reused if inspected, validated and cleaned. The problem is taking them apart. I developed this hammer tool to separate the plunger from the body. Insert the bucket (upside down) and secure with the cover plate. Next, a few good blows