Technological changes for diesel engines may often be viewed as complex, but once they are understood, validate the performance and efficiency benefits we appreciate today.

Common rail injection for mid-size trucks has been around for nearly 15 years. While many owners appreciate the quietness and dependability of their diesel engines, many have no clue as to what changes have taken place to the fuel system in order to not only make their diesel perform, but also be emissions-compliant. For the most part, common rail is simple in design, but can be quite complex thanks to the related parts and sensors that create the orchestra for the system.

The benefits of Common rail are:

- Higher injection pressures which produce finer atomization of fuel;

- Fuel pressure available “on demand”;

- Injection pressures created independent of engine speed;

- Multiple injections per cylinder combustion are possible;

- Reduction of exhaust emissions;

- Reduction of particulate emissions;

- Noise reduction;

- Fuel efficiency; and

- Higher performance.

The diesel fuel system can be divided into three basic circuits consisting of supply, pressure and return. The Common rail system starts with a high-pressure pump, usually manufactured by Bosch, Denso or Delphi. Even though the pumps may vary in design, the basic principle is the same. The pump is engine-mounted and driven from the front or rear gear train of the engine.

The low-pressure circuit consists of the fuel lines from the fuel tank through the fuel filter and to the high pressure pump. Bosch-style pumps have a transfer pump built into the body of the pump housing. Fuel is drawn in from the tank and through the filter to supply the high-pressure pump. For Denso-style pumps, fuel is supplied to the pump, usually from an electric in-line or in-tank pump.

The high-pressure circuit consists of fuel that is pressurized by the high pressure pump. As fuel enters the pump, there are pistons and valves that that make up what is known as pumping chambers where the fuel is pressurized.

A regulator is placed in the pump to control the amount of fuel that will enter the chamber. Once the fuel is pressurized, it then enters a high-pressure steel tube and is carried from the pump to the “Common Rail.” The pressure generated by the pump can range from 5,000 psi at idle to 23,000 psi and upwards of 28,000 psi on newer systems at wide open throttle.

The “Common Rail” (also known as an accumulator) looks like a thick steel log with high-pressure steel lines extending from it to feed the individual cylinder injectors. A fuel pressure sensor on the common rail informs the ECU as to how much pressure is inside the accumulator. The ECU then controls the regulator of the high-pressure pump to obtain the desired amount of pressure for maximum efficiency.

There are advantages to having a regulator that controls intake volume of the high pressure pump: only the required amount of fuel is supplied to the pump to be pressurized. This keeps fuel return at a minimum, which helps reduce fuel temperature. Less load on the pump reduces parasitic load on the engine, which helps to reduce emissions.

In a case where there is too much pressure in the common rail, there are two types of reliefs that can be found depending on the vehicle’s system. One type of relief is known as a mechanical pressure limiter. The limiter is placed at the end of the common rail and consists of a spring-loaded plunger. If excessive pressure is reached in the rail, the valve opens and the fuel is dumped back to the return.

There is also an electric version of this seen in newer systems, known as a fuel rail pressure control valve solenoid. This valve is controlled electronically by the ECU and because of its faster response time is able to more quickly relieve excessive fuel pressure in the common rail.

Next for the high pressure system are the injectors. The injectors are electronically controlled by either a solenoid or piezo actuator and are energized by the PCM with multiple injections per combustion event. This is where we need to take a look at multiple injection events and what they mean.

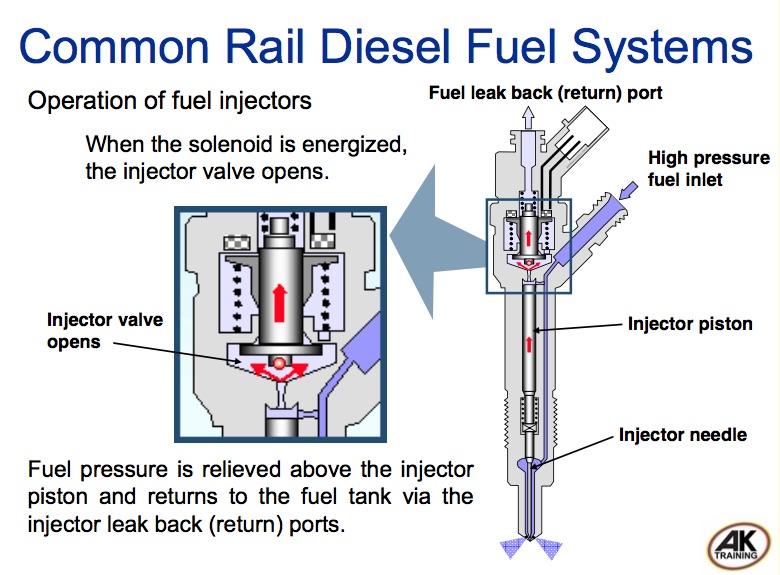

High-pressure fuel is supplied to the fuel injector from the tubes extending from the common rail. Fuel flows inside the injector to a needle and seat and also to a small chamber above the injector piston through a small, calibrated port.

When the solenoid is energized, the injector valve opens. Fuel pressure is relieved above the injector piston and returns fuel back to the tank via the return system. This creates a pressure difference above and below the injector piston.

Fuel pressure below the injector needle lifts the needle off the seat. High-pressure fuel then enters the nozzle where it is sprayed into the engine cylinder in micro fine droplets. The processes of the injector to perform injection happen at a very fast pace and is usually measured in milliseconds. As mentioned earlier, the injector can perform these events as much as five times per combustion event. Here is how the five injection events take place:

- Pilot Injection – This takes place as the piston begins its travel up the cylinder bore shortly after Bottom Dead Center. This injection event allows a small amount of fuel to enter the cylinder to let the fuel and air begin to mix.

- Pre-Injection – This is where an amount of fuel is added again to shorten the ignition delay for the main injection. This helps reduce noise or what is known as “fuel knock” when the main injection takes place. This injection cycle also reduces engine vibration along with reduction of NOx (Nitrogen Oxide) gas.

- Main Injection – This injection event provides fuel needed for combustion and power.

- After Injection – This injection event occurs in a split-second after the main injection. This helps burn any remaining PM (Particulate Matter).

- Post Injection – This injection event is used for what is known as “REGEN” or regeneration to clean the DPF (Diesel Particulate Filter).

All of these injection events will take place in approximately 0.4 milliseconds per combustion event.

In 2007 and newer vehicles, if there is an injector failure, the replacement of the injector can present a challenge. While the job itself may not be difficult for someone to perform, the ECU on the other hand will need to be programmed with the new calibration code from the replacement injector for the engine to perform correctly. The injectors trim code relates to the flow rate of the injector. The ECU uses this code to correct the injection quantity to compensate for manufacturing tolerances.

This is a basic overview of the common rail injection system. Please keep in mind that all sensors and actuators are controlled and monitored by the ECU. In addition, some sensor and wiring problem issues that lead to poor drivability along with erratic idle or stall may still need to be diagnosed by a qualified technician.