Understanding Bearing Clearances: Part 2

Bearings may seem simple, but bearing selection, fit and installation can make or break your engine build. Steve Morris explains in part 2 of understanding bearing clearances.

Understanding Bearing Clearances: Part 1

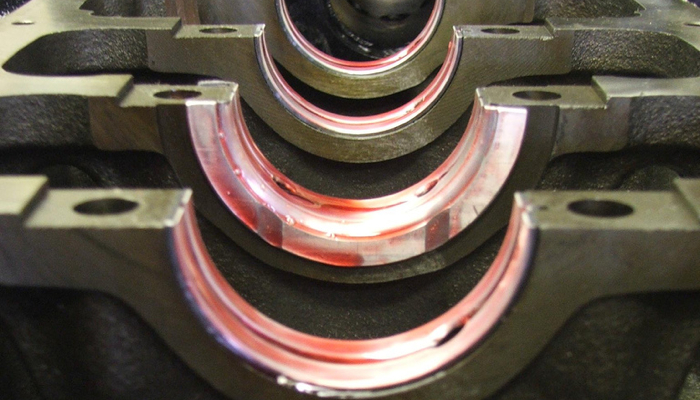

Proper bearing clearance is a recipe that includes three key ingredients: the bearing, the crankshaft and oil.

Bearing Clearances

Is it better to build an engine with tighter bearing clearances and run it on low viscosity synthetic motor oil, or is it better to build an engine with more traditional or even looser bearing clearances and use heavier viscosity oil? Tight bearing clearances and relatively thin synthetic multi-viscosity motor oils work well in many

UNDERSTANDING OIL CLEARANCES IN ENGINE BEARINGS

One way to make engines live and have good durability is to have just the right amount of bearing oil clearance. Maintaining a cushion of oil between the bearing and shaft is essential for proper bearing operation and to prevent metal-to-metal contact. Generally, tighter oil clearances are better due to the increased load distribution resulting

PERA to Host Webinar on Race Engine Bearing Lubrication, Clearances and Tolerances

Ron Sledge of King Engine Bearings will help you discover the principles of proper bearing lubrication and bearing clearances working hand in hand to provide the most trouble free operation for your racing application.

King Engine Bearings Anounces New Rebate Campaign

During the two-month duration of the campaign, customers can take advantage of a rebate of $10 for every $100 spent on qualifying pMaxKote (XPC) products by King Engine Bearings.

Facts About Engine Bearings

The experts all agree that cleanliness is the most important factor during installation, and the lack thereof is the most common problem that leads to bearing failure. But measuring is just as critical.

Solving Engine Bearing Fatigue Failures with Silver Based Materials

One of the most important engine bearing properties is fatigue strength. Fatigue cracks start on the surface and then penetrate into the material. All layers of a multilayer bearing material must have fatigue strength that is greater than the actual load applied to the bearing. Engine bearings must work in a fully hydrodynamic oil film

Engine Bearings’ Impact on Performance

Nowadays, a bearing (in a performance setting) must be both hard and soft. Retaining geometry is of utmost importance, but it also must be malleable and able to adjust for stress and flexing.

Engine Bearings: To Coat or Not to Coat?

When it comes to keeping your engine happy and operating well, engine bearings are a component that play a big role in that regard. They’re small and relatively inexpensive when compared to other engine parts, but if an engine bearing doesn’t do its job, the consequences can be many.

Oil Clearances and Options for LS Engines

Oil clearances will not always be the same for each application. It is up to engine builders to decide what your customer’s oiling needs will be.

Engine Bearing Supplier Q&A

It’s hard to believe that such small shell-shaped parts can be in charge of so much in the life of an engine, but that’s just the way it is.

Engine Bearing Materials and Selection

One thing every engine builder and even non-engine builder types know is that metal on metal contact is not good. It’s so bad that engine builders will go to great lengths to prevent it from happening. Bearing manufacturers and coating companies also work hard to make sure that their products can withstand extreme abuse without destroying expensive components.

High Performance Engine Bearings

Building a high performance engine is always an adventure. You never know how much horsepower and torque an engine will make until it’s on the dyno. And you never know how well the engine will hold up until it is put to the test on the strip, race track, street or water. The bearings that

Engine Bearing Technology – The Spin on Spun Bearings

One of the worst failures that can occur inside an engine is a spun bearing. It can happen in a stock engine, race engine, gasoline engine or diesel engine. A spun bearing is bad news because it usually seizes itself around the crankshaft journal. What happens next depends on the bearing’s location.

PERA To Host Free Race Bearing Webinar

The Production Engine Remanufacturers Association (PERA) will host a free webinar on Wednesday, January 18 2017. The subject – “Racing Bearing Lubrication, Clearances & Geometric Tolerances” – will be presented by Ron Sledge of King Engine Bearings. “Just when you think you know all about bearings, Ron comes up with new insights into helping your engines last,” explains Joe

Engine Bearings – Main and Rod

The bearings that support the crankshaft play a critical role in handling the power the engine produces as well as engine durability. Because of this, bearing selection, fit and installation can make or break your engine build.

Engine Bearings Under Pressure

Today’s hi-flow, aftermarket, CNC-ported cylinder heads, high lift killer cams and induction system power adders (blowers, turbos and nitrous) are making more power than ever before, and really hammering the bottom end of the engine. If the bearings can’t take it, the engine won’t last.

Honda K-Series Engine Bearing Identification, Installation

Honda uses a specific bearing selection process for both rod and main bearings. It includes using a chart along with the identified parts included in the engine being rebuilt. Connecting rod bearing selection uses 4 possible rod journal codes to match with 4 big end bore codes that are color coded based upon size. A

Cam Bearing Selection and Installation

Replacing camshaft bearings during an engine rebuild is a no-brainer, but don’t take the process lightly. Simply knocking out the old bearings and installing fresh ones with little regard to bearing selection, sizing or alignment is a big mistake.