Not that I don’t support

the environment and being responsible in our efforts to save the planet

– I do. But the passion for the thunder of a throbbing,

pavement-pounding V8 is, well, similar to that of the how your heart

skips a beat when you think of your first love. What if you could still

have the power, have great fuel mileage and still be environmentally

responsible? That might be worth a Nobel Peace Prize in the eyes of

many automotive enthusiasts.

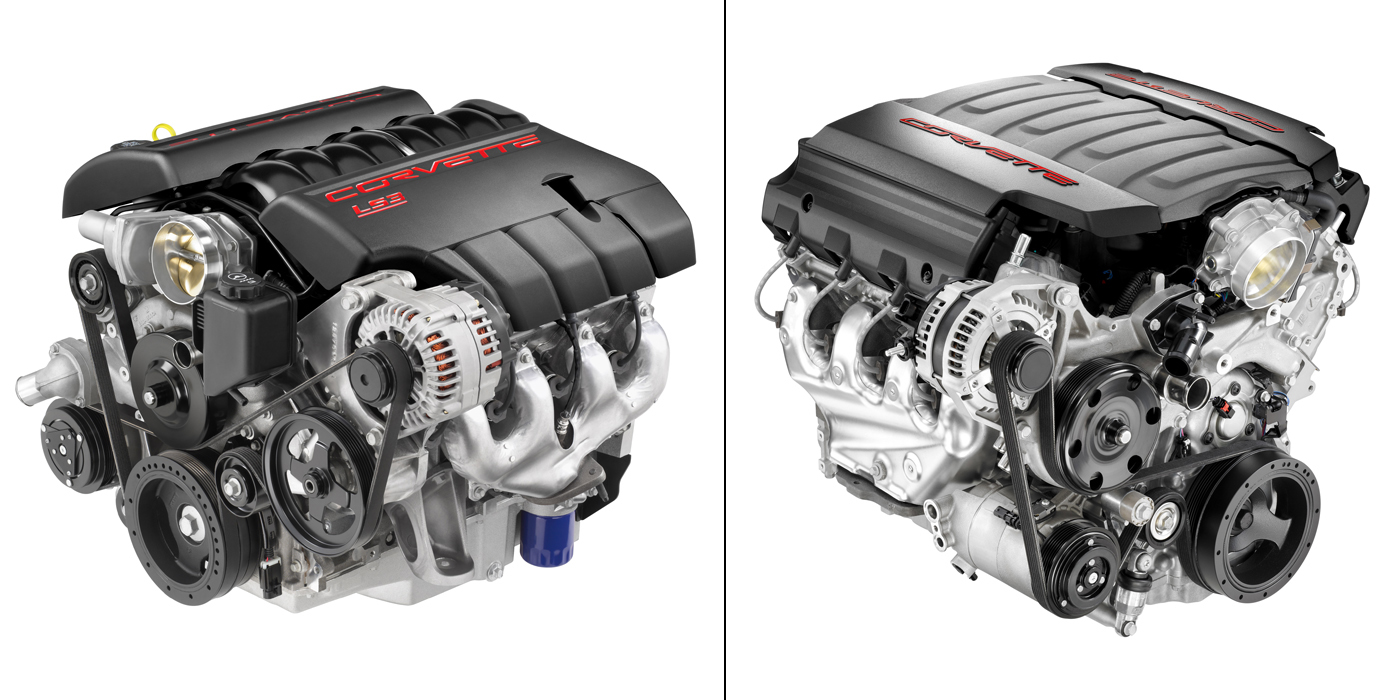

There are technologies that have emerged in recent years that

allow this to happen. I began last year with a similar hope for the

future when I spoke of displacement on demand (or whichever name a

particular manufacturer uses) technologies that will cut out cylinders

based upon demand of power required, so a V8 may only use 4 cylinders

while at cruising speed on the highway. But more recently, the use of

variable valve timing (VVT) in numerous engines has brought an entirely

new light to the situation. Case in point: the L99 GM engine in the ’10

Camaro with 400 hp /410 lb.ft. torque Gen IV 6.2L that implements both

technologies.

Now, this technology isn’t new by any stretch of the

imagination. It was toyed with as early as the ’60s by Fiat, and who

has not heard of the i-VTEC engines by Honda more recently? The initial

impetus to put VVT systems into production cars was the ever-increasing

pressure to meet environmental goals and fuel efficiency standards

while still maintaining reasonable performance. With today’s VVT

systems, engines are so efficient at reducing emissions that the

notorious separate EGR valve has become virtually extinct. VVT provides

sufficient passive EGR charge dilution that considerable fuel economy,

idle, and emissions benefits are achieved without the need to resort to

clumsy add-on devices.

Although not originally its main intent, as applied to

performance, VVT allows running a relatively radical cam that still

maintains a stable idle and low-speed drive ability. As I pointed out

above, VVT coupled with DOD should permit the survival of

large-displacement V8 engines for the foreseeable future. Generally

speaking, you want to advance a cam for more bottom end, higher vacuum,

and better idle characteristics. Retarding a cam aids the top end. A

typical production cam optimized for an advance/retard VVT system is

usually ground with reduced overlap, with VVT retard dialed in as

needed to maintain or enhance the top-end power.

Hydraulically actuated cam phasing is considered the preferred

method for variably advancing or retarding a cam. An electronically

controlled hydraulic valve or solenoid directs engine oil into a

camshaft phaser assembly that replaces the timing chain’s camshaft

gear. Inside the phaser cavity is a rotor that rotates within a stator

as needed to advance or retard the cam. An additional advance/retard

calibration table or map that relates cam lobe and crank position to

engine speed is added to the electronic control unit (ECU). Figure 1 shows a typical VVT operation.

Ford’s terminology for this technology is variable camshaft

timing (VCT). It’s available on SOHC modular engines with three-valve

cylinder heads. In 2004, Ford became the first to offer VCT in a pickup

truck, introducing the system on F-150 5.4L 3V Triton engines. Modular

4.6L SOHC 3V engines first appeared in the redesigned ’05 Mustang.

Since the SOHC V8 engine actually has two cams, one for each cylinder

head, there are separate phasers, valves, and actuators that bolt to

each head (Figure 2).

To supply the extra oil needed to actuate the two phasers, VCT

engines use a new, thicker oil pump that supplies 30 percent more

volume than even the higher-volume pump used on DOHC 4V engines. Losses

from internal oil bleed-off are reduced with the use of new, rounder

(less eccentric near the parting line) main bearings. Ford says

mysterious cam phaser actuation problems can be minimized by using the

new factory main bearings and sticking to factory production main and

rod bearing clearances. Which is why I have brought you here in this

article: main bearing clearances are .001? to .0015? and if you get

outside of that the phasers will rattle like mad, making a horrendous

racket.

The phasers can actually be taken apart and inspected (Figure 3) and, believe it or not, they are pretty straightforward as far as

component inspection for wear. There is one area that you need to be

aware of, however. There is an oil flow control valve and spring with a

“plastic” component that will wear, especially if oil has not been

maintained. If it goes bad then you will need to replace the phaser

since there are no parts available that I have been able to find. With

the three-valve engine being used in Ford trucks you can expect to see

them showing up in your facility. Be certain to verify that they are

viable and can be reused, or simply replace them (a step which will

substantially increase your reman cost).

If you did not get the

caution earlier, main bearing clearance is critical for oil volume, and

phasers do require a bunch. When going undersize on the crankshaft you

will most likely need to adjust your journal size for proper clearance,

I strongly suggest you install bearings into the main bearing housing

bore and determine what crank size you will need. If not, you may get

that phone call that says “my engine sounds like a freight train

rattling down the road.”

Roy Berndt has decades of machine shop experience. He is the EDS Data Acquisition Contractor for the Production Engine Remanufacturers Association (PERA), and Program Manager for PROFormance Powertrain Products, a PER in Springfield, MO. You can reach Roy at [email protected].