The magic number for engines in today’s day and age seems to be 2.0. Whether its Jaguar Land Rover’s newest line of four cylinder “Ingenium” gasoline and diesel engines, or the 400 horsepower Volvo four we detailed a couple of months back, the prevailing mantra of the industry seems to be ‘smaller, yet more powerful.’ Now, Volkswagen has decided to one up the rest of the industry by releasing a new small four cylinder engine that is every bit a potent as it is advanced.

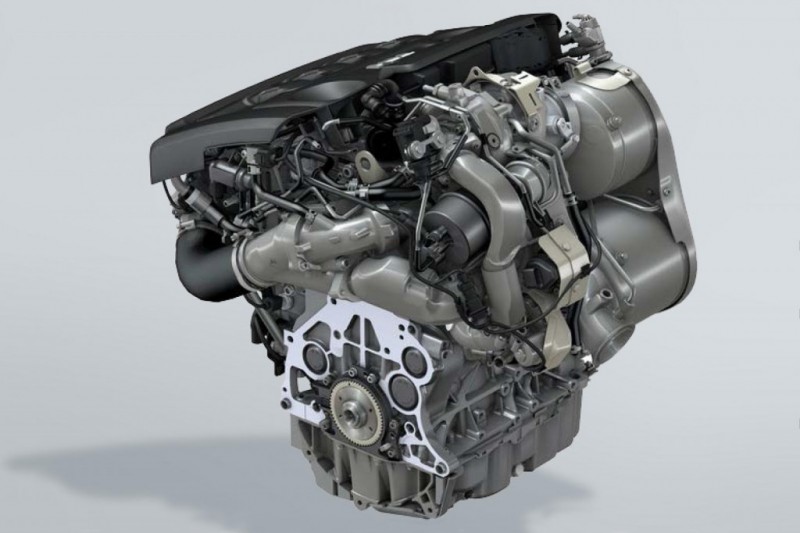

Volkswagen’s 2.0 liter diesel four cylinder engine produces 268 horsepower and a yet unspecified torque figure; most are anticipating the torque number to be well over 400 ft. lbs. Whereas Volvo’s newest four cylinder produced an obscene amount of power, it’s figures were misleading; the Volvo power unit was a hybrid setup employing electric motors to augment the internal combustion engine. Volkswagen’s new engine uses no such aids; however, that doesn’t mean that VW won’t choose to couple the engine to such technology, though the fact that it’s a diesel makes this unlikely.

With a power to volume ratio of 134 horsepower per liter(more than Ford’s renowned 1.0 liter EcoBoost,) the Volkswagen 2.0 employs Formula 1 grade technology yet reportedly achieves record efficiency; these figures haven’t been released yet, but you’d be safe counting on them being stellar.

As a rejuvenation of the current VW 2.0 liter diesel found in the non-US Passat, the new engine adds several salient new features and upgrades. Variable valve timing is a new feature, and so is a special start-stop system, which shuts off the engine in the event that the car’s speed falls below 7 miles per hour.

The new 2.0 does add an interesting twist where fuel injection is concerned. Instead of employing the time-tested PD unit injector fuel delivery system, VW went with a common rail injection system, delivering fuel directly to each combustion chamber. The new common rail system delivers fuel at a very high rate, operating at nearly 36,000 psi, or 2,500 bar, which is higher than the current VW TDI engines utilizing unit injection.

A piezoelectric system is used in the fuel injection system. This technology uses quartz crystals situated within the injectors, which expand when electricity is applied. Because the voltage applied to each injector can be manipulated and fine tuned by the ECU, it heightens the precision and efficiency of the injection process.

Perhaps the most technologically advanced aspect of the engine is its turbocharger unit. The turbocharger employed here is Formula 1 grade. Stemming from Audi technology soon to be employed on the next R8, the design essentially uses an electric motor to drive the compressor at lower rpm ranges.

This design will employ an electric motor to drive the turbo at lower rpm, until engine output is sufficient to drive the turbo by exhaust gases. Now, instead of waiting for the exhaust gases to reach a suitable level, power is available almost instantaneously. In Formula 1, the power for this system comes from the KERS system.

However, it’s not known how VW’s system will operate; this is what suggests a hybrid system or, more likely, a regenerative braking setup may be employed. The engine already has sufficient power to obviate hybrid setup, so that may be more unlikely. Another curious aspect of VW’s improvisation of this turbocharger design is the fact that, in addition to being electrically driven at lower outputs, the engine employs a “twin-turbo” setup. The question of the function of the second turbo is a mystery. Given that the engine is a straight four, that rules out the possibility of a parallel setup, and a sequential setup would seem unlikely due to the presence of the electrical unit; however, a sequential setup is very likely the case, though it does seem like overkill. Perhaps, drawing on efficiency concerns, one compressor may be driven electrically, while the second may be much larger and driven by an exhaust turbine; though the first compressor would then technically be reclassified as some sort of supercharger.

The engine will be coupled to Volkswagen’s new ten speed dual clutch transmission, pictured below. The ten speed is of the direct shift gearbox design, which allows either automatic or semi-automatic modes of operation. It replaces the current line of six-speeds and constitutes part of VW’s efforts to drastically improve fuel efficiency across their model range.

Arriving within the next couple of years, this new engine will be one of the more advanced on the market today. It represents Volkswagen’s continued commitment to building diesel engines for passenger cars- a trend which seems to have caught on everywhere but in the US. Also of interest is the usage of the electric turbocharger technology. This will be the first usage of the technology on a road-going car. Naturally, however it is curious and even ironic that Volkswagen beat both Ferrari and Audi to the punch.