KEYWAY TO SUCCESS

This tip is for the shops that need to cut a second keyway on crankshafts. This tool was made from an old harmonic balancer that I cut the center out of. I cut a second keyway at 180 degrees opposite of the original. Now this allows me to easily set up and locate the second keyway on the shaft in the mill. It can be reused as a pattern over and over again.

John Chavis Jr.

The Power House

Rockingham, NC

MDS PLUG POPPER

Some of the late model Gen III Hemi engines have plastic plugs in place where the MDS solenoids locate in the valley. They need to come out for block cleaning. They can be stubborn or even break when trying to remove. There is a small oil port near the lifter bores that goes directly to these solenoid plugs. If you pressurize this port with a rubber tip blow gun, while prying up on the plastic plugs, they will pop right out. Note: Stay clear because they will fire out like a bullet.

Nick Jones

Automotive Machine

Fraser, MI

KEEPING THE FLUIDS OUT

If you’re honing a block without a torque plate for any reason, use clear packing tape and cover all the water holes in the deck. This will reduce the drain time and you’ll see much less “walk off” of your honing oil as well. Saves money and reduces oil in your spray wash machine. Many times the water jackets will have scale or residue that will contaminate your oil too. This prevents that from being a problem.

Ron Flood

Cedar Machine

North Branch, MN

SIDE CUTTER UPGRADE

One of the most used tools in our shop is a good pair of side cutters. They can be a little messy with the clipped ends flying and sometimes unwieldy if you’re trying to keep multiple wires separate in your holding hand. To make them more functional, clean your side cutter very well. You might even want to scuff up the indented side for grip and then fill that space with silicone. Make sure to wipe it smooth and flush with the cutters. After the silicone has set up, cut straight down the middle following the natural cutters groove. You will now have a set of side cutters that will hold your material after cutting. This is helpful for keeping the cut piece out of a helper’s eye or holding the wire end that you needed.

Glyn Hassler

Diesel Air Systems

Jacksonville, FL

PISTON PIN POLISHING

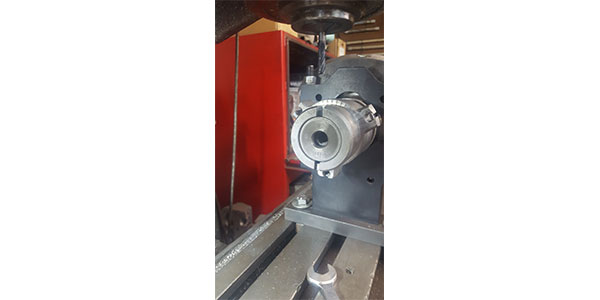

I found it easy to polish piston pins in the rod hone. I use a small mandrel to hold them.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

SECRET CLEANING RESERVOIR

I noticed a large area underneath the turntable in my spray washer that I put to good use. I purchased some 16-gauge perforated sheetmetal and fabricated a 10˝ deep removable reservoir. The solution is already spraying everywhere, so now I save a lot of time and energy cleaning smaller parts below the turntable. I have about $80 invested in it.

Dave Matton

D and D Auto Machine

Bloomington, MN