SUBARU CASE CLAMP

The Subaru opposed 4-cylinder has a split case or block. I came up with this solution to hold down Subaru blocks so we can surface them. It works real well and holds the block firmly in place. It’s a metal bar cut to fit inside of the cylinder. I drilled a hole in the middle to secure it to the surfacer table. The bar is 1/4-inch thick

Joe Werner

AMS Automotive Machine and Supply.

Fort Collins, CO

RING INSTALL PLATFORM

When I opened my shop, I used to struggle with holding pistons between my knees while installing rings. One day I noticed that on the common shop cart, most piston and rod assemblies would fit perfectly between the handle and the cart. It holds the piston stable and is also the perfect height for most chairs or stools to work comfortably from while you install rings. I wrapped painters tape around the handle and cart to keep from scratching the pistons.

Josh Townsend

Texoma Machine and Performance, LLC

Kingston, OK

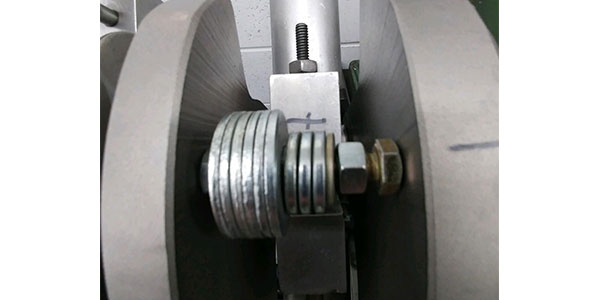

BALANCING ACT

When adding heavy metal to a crank while balancing, the correct placement can be determined by adding the effective gain of your tungsten slug by moving this adjustable device to the approximate location on the counterweight and dialing in the exact position to drill. By fine tuning the location of the final correction, I can relocate the location and minimize the material removed for final correction. Simple 5/16˝ hex coupling nut, bolts and washers.

Randy Quam

Competition Engines

Eagan, MN

WINDAGE TRAY WINDOWS

Many OE and even some aftermarket windage trays do not do a good job of draining the oil in the tray back to the sump of the pan fast enough. The two worst that come to my mind are BB Chrysler and FE Ford. The oil really pools up on this style and can only drain in the front or rear of the pan. While putting my own 440 together I came up with this easy fix. I cut three windows in the middle of the stock tray and welded in some uni-directional screen I had left over from an aftermarket kit. The screen is relatively inexpensive. It allows the oil to get away from the crank much faster than normal, which helps free up some horsepower and helps to keep the oil from being excessively whipped up by the rotating assembly, which can contribute to aeration.

Jake Sampson

Sampson Racing Engines

Inver Grove Heights, MN

GROOVY CAM BEARINGS

When boring cam tunnels for repair or index correction that have oil grooves behind the bearing, you will lose a little area in that feed. Instead of the hassle of grooving them deeper, I just make up what’s removed by grooving the backside of the bearing the same depth and thickness. When installed, no oil will be restricted.

Ron Flood

Cedar Machine

North Branch, MN

IS YOUR SHOP HYPERLOCAL?

How does a new potential customer find your shop? Yellow Pages are out… smartphones are in! Have you had occasion to type, or better yet, use voice commands with your smartphone to find a restaurant “near me?” This technology, called hyperlocal, combines internet business listings with the GPS in your phone to display, not just fast food joints, but any business. Now’s a great time to test Google to see if your business is listed. Type the name of your business into your smartphone web browser and Google should display a street view photo and a map of your location. If not, you need to claim and manage your company “Google My Business” page. Google allows searchers to easily find information about your business on search, maps and Google+. It’s free, easy to manage and gives you the control to present your local business in the best light possible. This works even if you don’t have a web presence.

Steve Rich

Sterling Bearing Inc

N. Kansas City, MO