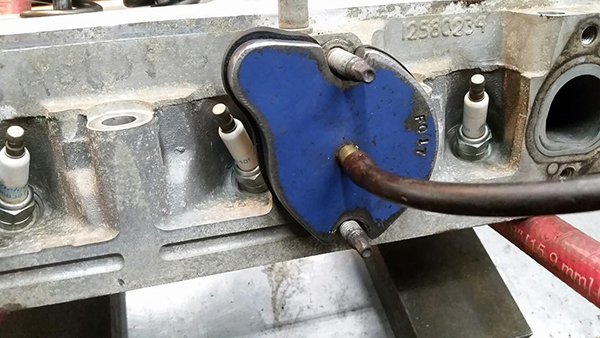

VACUUM TESTING FIXTURES

When vacuum testing valves on some heads there may be obstacles in the way. In many cases there will be some exhaust studs in the way like this 3.4L GM. Rather than opening up a can of worms trying to remove the exhaust studs, I look through my pressure testing plates to see if something fits. This is one of the more common heads I do and this plate from a Ford 2.3L fits this and several others perfectly.

Dan Matton, D and D Auto Machine, Bloomington, MN

WINGNUT DRIVER

I balance several engines a week. While correctly loading a bob-weight is very important to the end result, spinning down multiple wing nuts is simply routine and time consuming. I made this notched tool from aluminum tube in two sizes. You can also knurl the OD for easy grip. It is like using a screwdriver to spin wing nuts on and off, faster and much easier on your fingers.

RC Whitcomb, Northend Auto Parts, Yuma, AZ

TOOL TIP

When cutting main caps for line honing, this easy tool makes checking your work as you go a breeze. It’s especially useful if you need to cut different amounts from each cap. It’s great for searching through your old main cap selection if you’re looking to replace one on a block.

It works for many other uses around the shop as well. I made this from an eBay purchased dial indicator and a piece of aluminum with a thumb screw.

Ron Flood, Cedar Machine, North Branch, MN

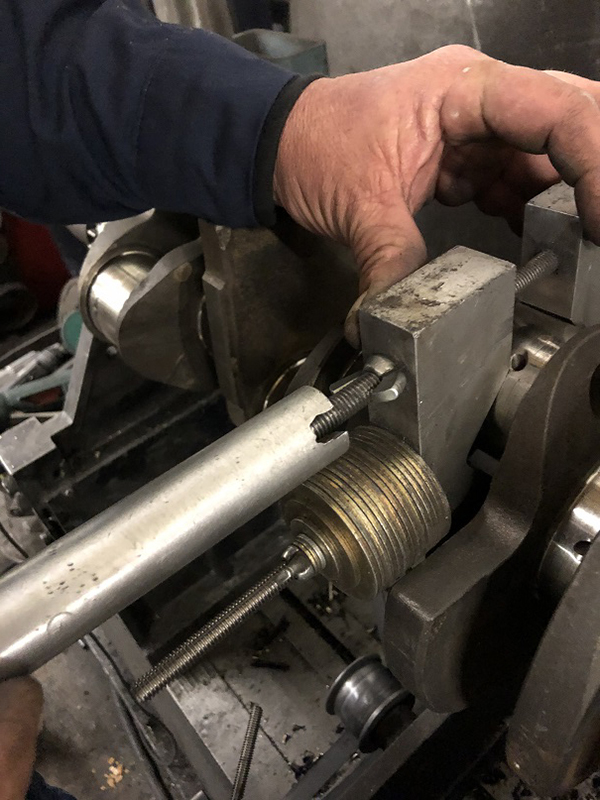

MANDREL FOR MACHINING OLD RETAINERS

I had a different combination of valve stem and spring diameters to work with and I could not find spring retainers to fit. I had previously made these mandrels to hold and modify 7° & 10° retainers, so this job was easy to complete. With another simple mandrel, “O.D.ing” valve seats is easy as well. Keep the old parts and use or modify them for the next job.

Randy Torvinen, Torvinen’s Machine, Menahga, MN

ORGANIZATION FOR EFFICIENCY

I’ve found dollar store mini muffin tins are great inexpensive part organizers. I use them for bucket style solid lifters that are found in many late model DOHC heads. They enable me to easily put them back in the original positions. In this picture, I used them to keep rod bolts in the same locations as the rods after I had measured the new length and recorded it for the customer. The next time this engine comes in for a freshen up, we can verify the bolt lengths to ensure the bolts have not yielded. The tray even makes washing parts a little quicker. As we all know, the fewer times you change tools in your hands, the more efficient you can be.

Jake Sampson, Sampson Race Engines, Inver Grove Heights, MN

INNER TUBULAR

For the past 20 years, I have been buying bicycle inner tubes at the local hardware store to replace the neoprene sleeve on our universal cam bearing tool. The inner tube costs range from $5.99-$9.99 and will give

you more bang for the buck. Cut the inner tube with scissors to the sizes needed. Neoprene replacement sleeves range in price from $7.99-$11.99. Depending on how many cam bearings you remove and

install, the inner tube can last a long time. If it’s covered in oil, cut a new piece of tube and install for a cleaner install.

Randy Kalis, Kalis Repair & Machining, Royalton, MN