As more and more people are building high-performance import engines, the need for more robust transmission components is growing as well. These transmissions for Hondas, Nissans, Subarus, and even European nameplates, can withstand some power boosts. Still, when they reach a certain level, turning the gears into paperweights is a risk.

David Gammon, operations director, Pfitzner Performance Gearboxes, spoke to us about the need for upgrades in the driveline to match the engines’ power.

“In terms of our outlook on the sport compact/import market, we dominate the whole field by the number of racers running PPG. We have some competitors now in the all-wheel-drive segment, but they were all sequential gearboxes. We have that also but are more known for our H-pattern Honda B series and K series transmissions, which we have done for years.”

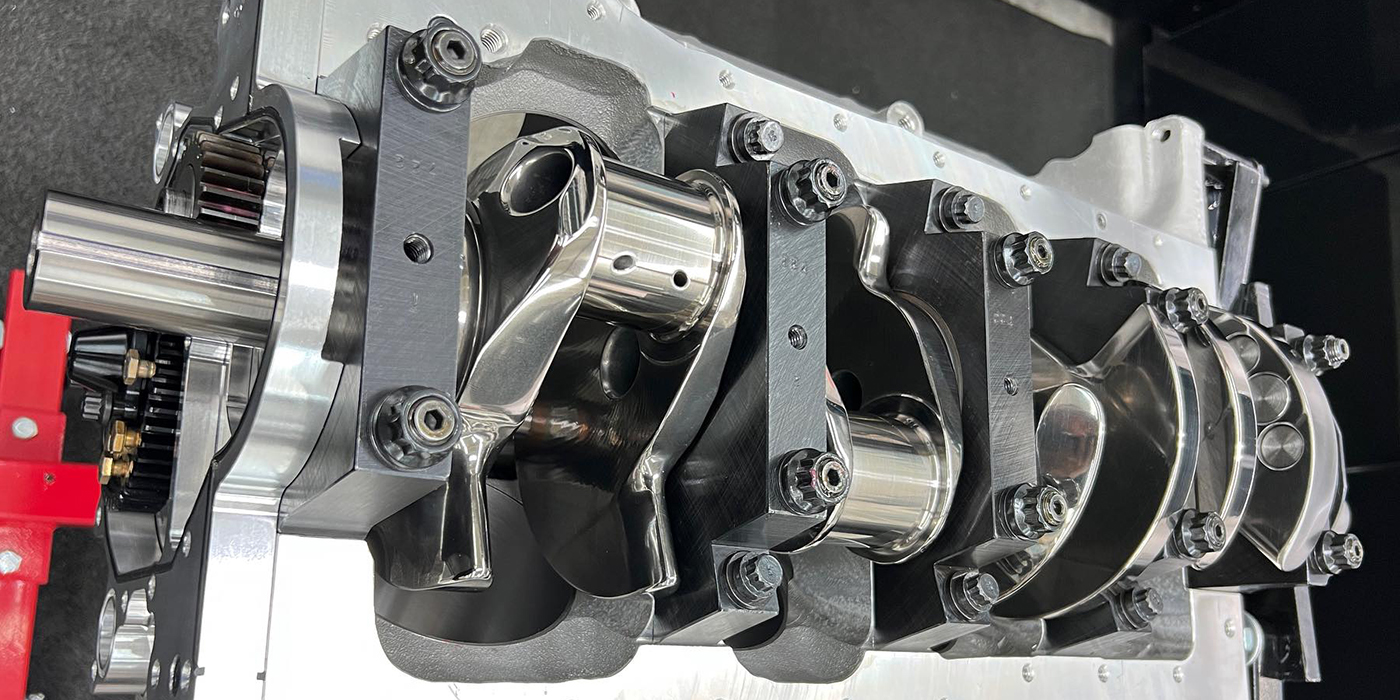

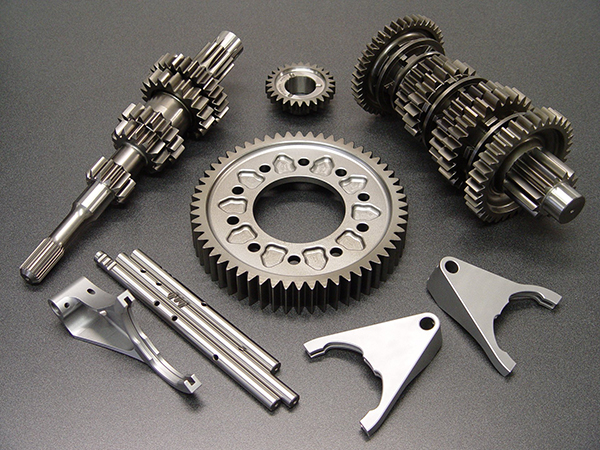

PPG’s H-pattern gear sets are available for a wide variety of sport compact applications. The H-pattern is where it all began for PPG. The company was formed because they saw the need for performance gear sets to replace OEM gear sets for high-performance cars. Founder Simon Pfitzner and his business partner at the time realized there was an opportunity to manufacture and supply this growing marketplace with high-performance gears.

Cars with manual transmissions are equipped with synchromesh helical gears from the factory, allowing smooth gear changes and quiet operation. These gear sets usually last the life of the vehicle and are only built to handle the stock engine’s horsepower.

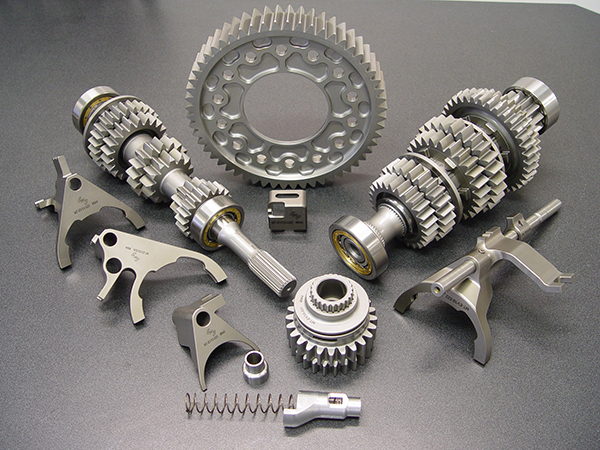

But ever since cars have been racing, there’s been a desire for quick shifting, and the synchromesh design can only shift so fast without causing damage. Dog-tooth-style gears are used in racing applications to enable faster gear shifts in what is called a “dog box” transmission.

A dog box uses a dog engagement set up that replaces the synchromesh system. The dog engagement system goes back to old agricultural machinery, and they required a fair degree of “mechanical sympathy” to change smoothly.

The difference between the dog tooth set and a synchromesh system is that the speed is not limited for making gear shifts, making them better suited for motorsports applications.

In a manual transmission, the synchro or dog teeth allow each gear to engage another gear. A straight or helical tooth design run at the same speed as the input gear to mesh with the mating gear to make the gearbox drive the output shaft.

PPG offers both helical cut gears for street applications where there’s a need for quiet operation and smooth shifts, but most of the gears they sell are straight cut. Transmissions with straight-cut dog engagement are more durable for heavy-duty and racing applications.

“We specialize in the OEM case H-pattern because a lot of rules say you can’t use a sequential gearbox,” says Gammon. “The Honda segment is our core market, but if there are any special things people want us to develop in-house and go to market with it for their own products, we do private label as well. But the Honda market has been very good to us over the years.”

The benefit of using straight-cut gears is they don’t produce an axial load. On helical gears, thrust is generated by the sliding contact between the teeth, creating lateral forces on the input shaft. In front-wheel-drive applications, the lateral force will be transferred through the driveshafts. The amount of torque that can be applied through the gears before failures on other components occur is limited.

Straight-cut gears effectively allow much larger powertrains to be placed in a vehicle without risking the output shafts and other bearings tearing themselves apart, producing a larger safety factor within the transmission itself.

The age of the standard H-pattern transmission is on the decline. The majority of new cars in the U.S. have an automatic transmission, and some performance vehicles use a dual-clutch transmission (DCT). A DCT can shift quicker than an H-pattern, but they can only select gears sequentially, which significantly reduces the chance of a missed shift. These transmissions use helical gears as well and may not be strong enough for high output engines. Some of the European car companies adopted the DCT several years ago, such as BMW and VW, and have been phasing out most of their manual transmissions ever since.

Many Evos and GT-Rs are equipped with DCTs. While it has taken some time for racers and the aftermarket to figure them out, the DCT appears to have some distinct advantages in certain forms of racing. When engine builders and tuners first started building the VR38 GT-R engine, many were skeptical of the DCT. The complex electronics involved with how the DCT operated created a lot more friction and were slower than a manual or sequential transmission. But after tuning the transmission control module (TCM), the DCT came to life. While a DCT is not for every racing application, mostly drifting, it does have advantages.

According to Gammon, the all-wheel-drive systems found in Mitsubishi Evos were considered nearly unbeatable in import drag racing. The world record was held by an Evo that turned a sub-8-second run. These require robust transmissions with precise shifting to transfer all the power to the ground. Some Honda racers are running an AWD setup out of the CRV that makes them competitive with the Evos.

“For years, the Mitsubishi Evo was always predominantly a rear-wheel-drive off the line,” says Gammon, who is also a chassis engineer by training. “It was 60-40 or 70-30 to the rear split. What used to happen with the Mitsubishi is it would either spin or bog off the line. The Honda boys figured out what they could do with their platform was different. Their rear-wheel-drive systems were just the opposite with 25% to 30% rear-drive.”

Gammon says the Honda only put 200 to 300 horsepower through the rear. “Hats off to them because they got so much traction off the line. Now the Evo guys need to go back and revise what they are doing and move it to a front-wheel-drive car off the line.”

For import engines producing big horsepower, it’s crucial to use a transmission with enough torque capacity and proper gearing for the application, whether for drag racing, road racing or drifting. Most factory transmissions with helical gears won’t handle the higher torque of a performance engine. Why take a chance on a weak gearbox when close-ratio gears and upgraded internals could help your customer put down power? EB