A Diesel Engine Doing the Unimaginable

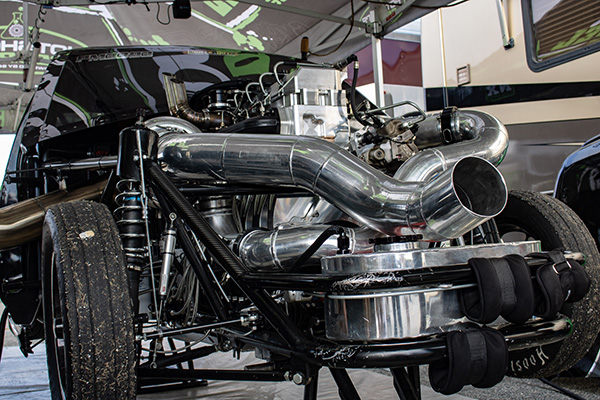

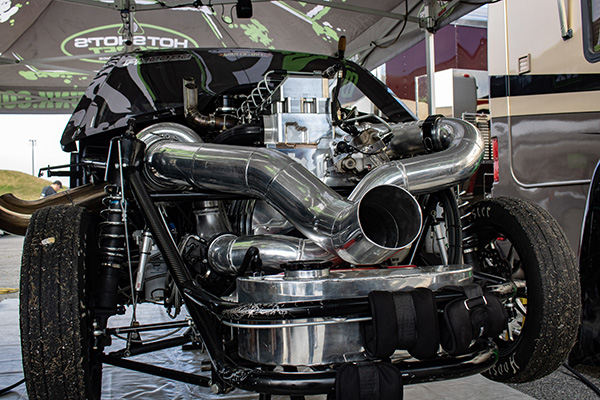

A new chapter to the drag racing history books was added back in late-February 2021, when Firepunk Diesel achieved what was once thought to be impossible – a diesel-powered vehicle running an 1/8th-mile pass in under 4 seconds.

Based out of Ohio, Firepunk Diesel’s S10 went down to Adel, GA to compete at Lights Out 12 at South Georgia Motorsports Park. Considered the baddest small tire race in the world, Firepunk’s Larson Miller was behind the wheel of the only diesel-powered vehicle there, going head-to-head against the nation’s fastest gas-powered race cars in the Radial vs. The World class.

The Firepunk Diesel S10 had already broken its own world record at the end of 2020 at No Mercy 11 with a stunning 4.11 pass at 181 mph. However, some off-season upgrades allowed the Firepunk race team to open the 2021 season with multiple new personal best times (4.10, 4.04, 4.04 and 4.00), but most notable was the world’s first ever 3-second diesel pass. The Firepunk truck shocked the drag racing world with a blistering 3.998-second pass at 182.67 mph during Lights Out 12.

“It’s a super accomplishment for our team. A ton of hard work went into this,” says Firepunk Diesel owner, Lavon Miller. “It’s something we’ve been chasing to get this truck into the threes and every time you go deeper into the fours it seems like it’s so close yet so far away and it finally all came together. It is really an accomplishment for the diesel world and we are glad that our team can be part of it. However, a truck like this doesn’t go this fast without a team of great people and companies supporting it. And it’s a big team… Hot Shot’s Secret, D&J Precision Machine, Exergy Performance, Nitrous Express, Menscer Motorsports, Neal Chance Converters, Rossler Transmissions, Fluidampr, TBM Brakes, and more.”

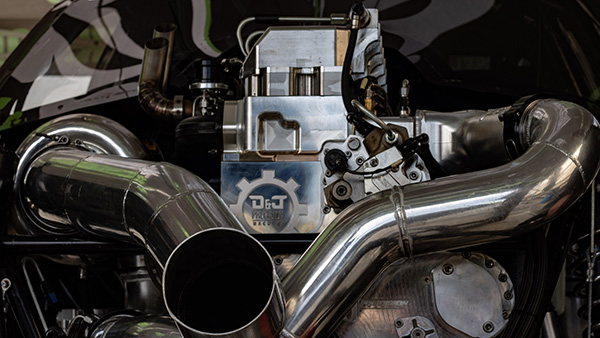

Of those many folks involved in Firepunk Diesel’s racing efforts, none are as important as D&J Precision Machine and Hot Shot’s Secret. Drew Pumphrey, owner of D&J Precision Machine, is the engine builder behind Firepunk’s 6.7L Cummins-based engine known as the Executioner. It’s a one-of-a-kind build.

“This build was something we both wanted to do,” Pumphrey says. “We saw that the Firepunk guys have been the ones abusing stuff the most, so we knew Firepunk was going to need an engine like this. We had a few block failures that we really couldn’t improve on with the factory block stuff, so we knew we had to keep moving forward. They wanted something lighter weight, so it was mutual wanting to do this build.”

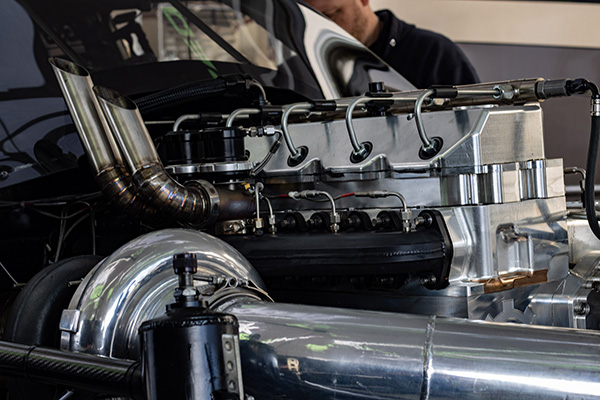

The Executioner

The state-of-the-art, 6.7L Cummins-based Executioner build started after D&J experienced multiple failures with the main web of the factory 6.7L Cummins block. Drew found he was unable to improve the factory block in this area, so he decided to start from scratch with a better design.

“The rules of several organizations say that a factory crankshaft must fit in the block, so we started with that and built everything from there,” Pumphrey says. “Our block was designed using FEA (Finite Element Analysis) software to allow us to remove unnecessary material. Our unique web design not only looks great but is 100% functional. We decided on aluminum for our block and steel for the bed plate.”

D&J uses six studs per main with about 2 inches of 5/8ths thread in the block. This provides over 1 million-lbs. of clamp force for the bed plate to the block.

“We are utilizing a billet Winberg crankshaft,” he says. “We manufacture the 1˝ longer connecting rods and forged steel ring land pistons in-house for this engine. We also raised the deck height 1˝ to improve rod-to-stroke ratio and are utilizing a roller camshaft in this engine for added durability.”

To seal the Executioner, D&J decided not to utilize a head gasket, but instead opted for o-rings.

“We o-ring seal the oil and use a reusable, spring-energized fire ring that originated in aerospace,” he says. “The 24-valve, billet aluminum cylinder head is held in place with a custom ARP 625 stud with 5/8ths thread in the aluminum. All the threads in this block and head are roll formed for the strongest thread available.”

When it came to the Executioner’s cylinder head, D&J had goals to have the lightest and highest flowing cylinder head on the market. In Drew’s words, the team crushed it.

“To meet our goals, our intake manifold could only weigh 10 lbs.,” Pumphrey says. “Not only did it have to be light, it had to flow well, distribute air evenly and hold up to 200 psi of boost. This alone took over a week to design using FEA testing to make changes to the designs.

“We were not happy with our first exhaust port design, and after several revisions, ended up with a now patented design for the exhaust port in our head. We have an exhaust port per valve in this head giving us 12 exhaust ports for a 6-cylinder engine. This unique design gave us an additional 100 cfm of exhaust flow, which translates to more horsepower and lower exhaust gas temperature and moves the industry forward.”

This required a custom exhaust manifold to be built to fit the 12 ports. Since nobody makes a 12-port exhaust manifold, D&J took it upon themselves to create it in-house. On the front of the engine, D&J designed a billet timing gear housing to eliminate the need to run belt-driven accessories.

“All of our accessories, including multiple high-pressure fuel pumps and the oil pump, are all gear driven,” Pumphrey says. “This gives our customers the most reliability available. We designed every part in this engine for maximum performance and durability.”

From the oil pan to the valve cover and every part in between, this engine was 100% designed and manufactured in the D&J facility in Cambridge, OH. To finish off the build, D&J relied on Exergy Performance to cover the fuel system with 650% over injectors and two 14mm race pumps. Controlling everything in the Executioner is a Bosch ECU and Powerbox, which was set up and calibrated by Exergy Performance.

Lastly, Fluidampr tested the engine harmonics and made sure their damper was properly tuned for the application, and Hot Shots Secret supplied all the essential lubricants.

“Since this is a new engine, we wanted to not only test the limits of it, but also do so with the most knowledge available,” Pumphrey says. “We are working with some of the best people in the industry on the development of this engine, such as Phil DeVries at Exergy Performance, who is helping every step of the way on all aspects of the fuel system and engine calibration. Without him we could not finish this project.

“We are also working with Kistler on in-cylinder pressure, which is giving us information no one has ever seen in a high-performance engine. This will help us design better parts for more durability as well as tuning strategies that will help save parts. Our goal is to make engines that will take the abuse that good customers like Firepunk Diesel put them through.”

As it stands now, Firepunk Diesel ran the Executioner engine for an entire season in 2020, and D&J says the engine came back in excellent shape.

“The short block has held up perfectly,” Pumphrey says. “The cylinder head we had originally done with a beryllium seat, hoping that it would hold up. We kind of expected that it wouldn’t, but with the way most of the gas guys and even Top Fuel get away with that stuff, we thought it was worth a try because it would be less expensive and easier to manufacture. We tried to do the cylinder head that way, but it really didn’t work very well at all. We had seats moving around on the cylinder head right away. It did make it all the way through the year with that head with some touch ups and fixing valve jobs and things like that to patch it up and get it out.

“I think it made 100 passes last year that way, plus the dyno stuff, so it was successful, but we still had more maintenance than what we really liked. This year, we revamped the cylinder head with an insert that goes the full length of the cylinder head and through the whole combustion chamber area with a different injector cup system. After seeing that come back from the first race of this year, I think with just a couple minor adjustments, it’s going to work really well.”

With a single GT55 turbo, nitrous and water injection aiding the Executioner, the engine is capable of more than 3,200 horsepower and more than 3,300 ft.-lbs. of torque. In order to keep an engine like this happy, the fluids and lubricants used are absolutely paramount.

Helping Wear and Tear

Hot Shot’s Secret sponsors Firepunk Diesel’s S10 Pro Mod race truck with all of the fluids and lubricants from bumper to bumper – engine oils, transmission fluids, gear oils, oil additives, fuel additives, coolants, spray lubricants, bypass filtration kits, as well as conducting all of their oil and fuel analysis testing.

“The Executioner engine in the Firepunk Diesel S10 uses our Hot Shot’s Secret Adrenaline R5 Racing Oil 20w-50,” says Kyle Fischer, Hot Shot’s director of branding and promotions. “We went through numerous formulations in the development of our Adrenaline line of racing oils with the help of Firepunk Diesel throughout the R&D process. It is often thought that the team receives some sort of special blend of oil, but in fact, the Firepunk team uses the exact same Adrenaline R5 oil available to all customers.”

Hot Shot’s Secret’s Adrenaline Racing Oil is built off a 100% full Group IV PAO base oil. The unique molecular structure of this synthetic oil resists shearing and will effectively maintain viscosity, regardless of the extreme loads put on it. In contrast, Group II ‘conventional’ and Group III ‘synthetic’ based oils can shear out of grade quickly under the tight tolerances of multi-thousand horsepower racing engines.

“The polyalphaolefin base oil we use has extreme shear stability, allowing for extended intervals in the racing application, while still maintaining protection for the engine,” Fischer says. “It is common for race teams at this level to change oil after just a couple passes. However, we have seen the Firepunk S10 make up to 30 passes before changing oil with resulting oil analysis still showing successful wear protection for the engine.”

The Executioner is no different from any other high-performance racing engine in that the rod and main bearings are commonly some of the greatest stress areas, especially under the 3,000-plus horsepower and torque loads the engine produces. For this reason, it is vital to have a robust additive package in addition to the base oil to prevent wear and failure.

“The protection package in our Adrenaline Racing Oil includes around 3,000ppm sulpher-based zinc (not phosphorus-based ZDDP), 1,000ppm calcium, and 1,000ppm antimony,” Fischer says. “This balance of high-performance anti-wear additives helps to prevent bearing failure under the extreme loads that the Executioner engine can produce.”

After 100 passes with the Executioner, the bearings hardly showed any wear. Aside from the rod and main bearings though, another area of common failure seen in this type of application is with the wrist pin bushings, which can egg out or roll over on the corners.

“After dozens of dyno pulls and over 100 full track passes on the Executioner engine in its first year of competition, the wrist pin bushings appeared to be still brand new with virtually no wear upon post-season inspection at D&J Precision Machine, even under a calculated 100,000+ psi of pressure on the wrist pins,” he says. “Further inspection showed the original bull nose on all of the rings, all of the original cross hatches in the cylinders, and the original coating on the bearings, including still visible measurement marks from the bore gauge during initial measuring before assembly.

“D&J reported that the most common area of lubrication failure they see is often in the ring pack and cylinder walls, but they documented lower crankcase pressures and reduced blow by due to keeping a strong oil film on the ring pack.”

One aspect of Hot Shot’s Secret Adrenaline Racing Oil that helps it achieve this level of performance is its patented nano carbon technology, which combines with the PAO base oil and anti-wear additives.

“Adrenaline Racing Oil is infused with our FR3 Friction Reducer oil additive, which is a nano carbon-based formula that finds and fills any voids in the metal surfaces with nano carbon balls that are smaller than a human cell,” Fischer says. “Whether it is a new engine with machining marks or an older engine with wear marks, these nano carbons fill all voids to create a completely flat film layer to which the nano lubricant can build from. This ultimately results in friction reduction, which lowers hot spots and operating temperature, providing longevity to the engine and allowing for increased horsepower.”

Diesel Innovation

While the Executioner engine has been at the heart of new diesel racing milestones inside Firepunk Diesel’s S10, no one is resting on their laurels when it comes to continuing to push the limits. Projects like this one help folks like D&J and Hot Shot’s make even better products for customers at any level.

“It means a great deal to us to see our products help contribute to the record-setting results that Firepunk Diesel has achieved,” Fischer says. “It truly is a team effort and we are honored to work with great partners like Firepunk Diesel and D&J Precision Machine, who are open to collaborating to push the limits of technology into new areas that previously were perceived to be impossible. It is extremely rewarding to play a part in the success and is the ultimate testimony to our science.”

According to D&J, the Executioner will finish out the 2021 season before any further developments will be discussed, but the shop has been beyond pleased with the engine’s performance and condition.

“As of right now, until they push things harder, I don’t see anything that we need to really improve on,” Pumphrey says. “Everything is holding up well for the level we’re at right now. If they end up starting to push up on horsepower more, and they can get it on the ground, then we’ll have to see what the next weak link is. For now, it’s humbling to be able to go out and compete at such a high level. I think the next of couple of years is going to be pretty exciting for the diesel racing world.” EB