You never know when you’ll be in the market for a new employee. You may be fully staffed right now, but what if you were to expand your shop, offer additional services, or need the extra manpower to handle the increased work volume? Or, what if you were to lose an employee to the competition?

In any situation, would you be prepared to handle that void and know where to begin your search for a replacement employee? Even if you did, are you going to find a qualified employee who has the skills and motivation needed in this industry to succeed?

With the goal of providing you with some insight and ideas on the best ways to recruit new employees for your shop, we asked our Instagram audience for their input on the topic, as well as a couple shop owners who have recently gone through the hiring process.

In our Instagram poll, 40% of respondents said they had hired new employees recently and 76% said it was not an easy task. Of those shops that hired new employees, 52% said their new hires were doing a good job and 48% said they were not.

We then asked where they had found their employees and the answers, as expected, varied quite a bit. Shop owners used anything from job sites such as Craigslist, Facebook, Indeed, LinkedIn and ZipRecuiter to more traditional avenues such as other shops, dealerships and tech schools. However, friend recommendations and word of mouth was still near the top of the list as the most common method. That seems to be for a good reason too.

“Those relationships in the industry hands down would be the biggest asset,” says Kill Devil Diesel owner Jared Alderson. “There’s a lot of tools out there for hiring people and getting your position in front of a big audience like with Indeed and ZipRecruiter. Those are great, but ultimately, the people in your circle or your extended circle, are part of your circle for a reason. The more you can pluck from that circle, the closer fit they might be. Not always, obviously. There are tons of good candidates out there we don’t even know exist yet.

“However, our best hires for sure have been the people that have the drive and want to learn. They’re not just looking for a job, they want this job. They want to learn and they want to get their foot in the door in the industry or they’re enthusiasts. That motivation factor is definitely huge.”

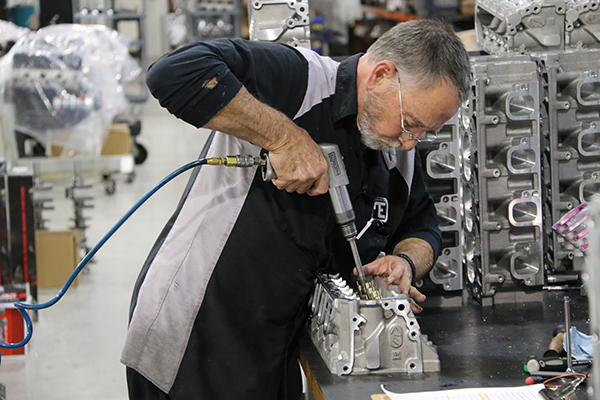

Alderson isn’t alone in this mentality. Whether shop candidates have any prior experience or not, the biggest factor to whether they will ultimately succeed depends on their drive and determination to want to be there and learn in an effort to be more helpful in the shop. The problem is finding folks with that drive.

“Everybody wants to be involved in this stuff until they realize what it takes to actually do it,” says Graham Jones of FastTimes Motorworks. “The technical ability just seems like it’s not there with most of the current generations. Trying to get anybody to want to do anything at all seems like it’s next to impossible.”

Not every shop has this issue, however, as many of the larger, bigger-name motorsports outfits typically get the pick of the litter when it comes to best candidates, since those shops are attractive destinations for younger talent. While this might be part of the reality, those shops are the 1% of the industry. The majority of engine shops around the country are in desperate need of additional manpower, especially today when demand for engines and engine components is sky high.

“We’ve been very busy, which is certainly a blessing given the times, but the growth and keeping up with the overwhelming demand of orders and customers doesn’t happen overnight,” Alderson says. “Most customers are pretty receptive to that, but some customers, in the Amazon age that we live in, want instant gratification. We are still a small, family owned business here in rural North Carolina and it can be difficult to respond to growth.”

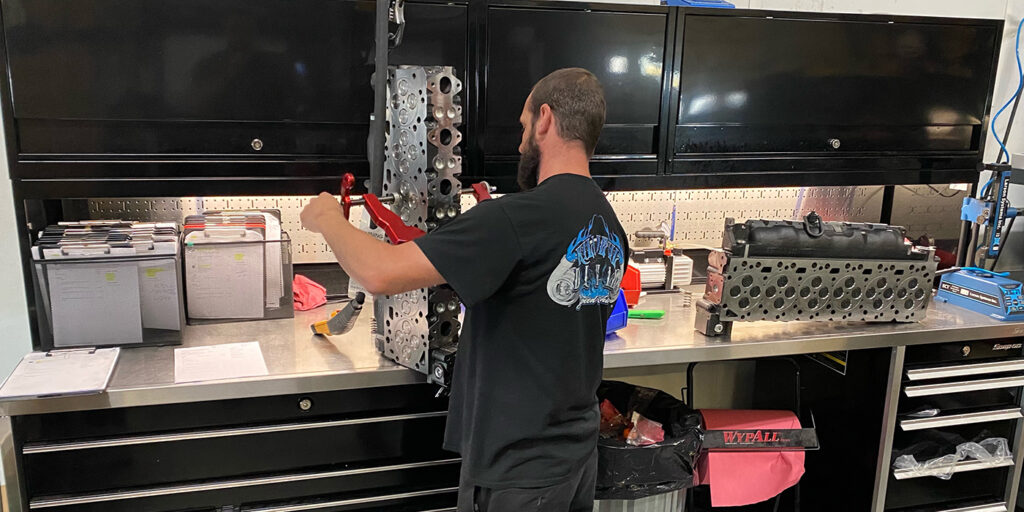

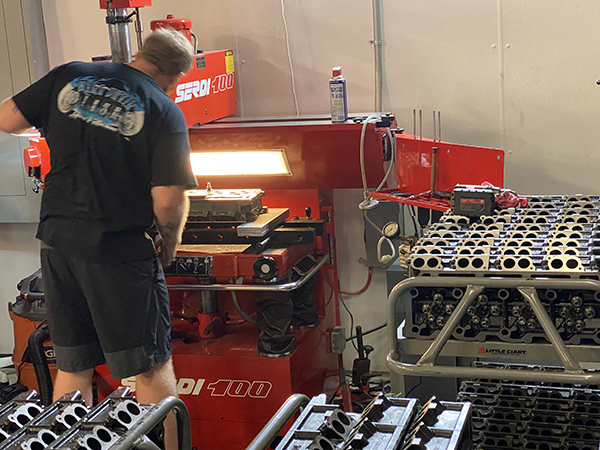

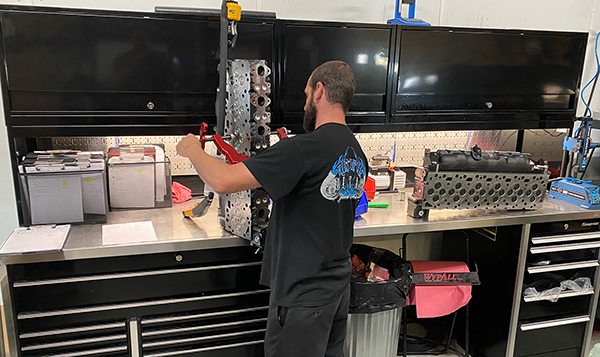

In fact, Kill Devil Diesel has double its staff in each of the past two years, and hired five employees in the last three or four months alone, bringing Alderson’s diesel shop to 16 total, which comes with a number of pros and cons.

“We’ve hired five people over the last three or four months now,” he says. “That’s been hugely helpful because that’s freed up some of our other employees to learn some of the more advanced machining to assume more of those responsibilities through the day. We could still hire another one or two people right now today. However, we need a certain sense of stability. We don’t want to hire 20 people in a month. It also kind of slows you down before you can speed up to get them trained and get them up to speed. It’s just part of it.”

In order to get new employees acclimated and to see if they sink or swim, Alderson says many new shop employees start in the disassembly/cleaning area.

“A lot of times we’ll start new hires in some of the disassembly/cleaning phase, because it helps show whether they have the discipline to do more or learn more,” he says. “It also allows them to learn the parts and the nuts and bolts. It’s a good proving ground before we can trust them with higher-level tasks like operating the CNC machine or assembling heads or assembling an engine.”

One thing on Alderson’s mind has been trying to keep up with the growth of his business, but also not growing too fast to the point where if an outside influence changed the amount of business coming in, he can still adapt.

“The hard part has been that these are uncertain times,” Alderson says. “To make the commitment to hire someone or not, I don’t want to hire someone and then six months later tell them sorry, we don’t need you anymore. That’s not fair to them and I don’t want to operate like that.

“You could hire just a warm body to come in and help, but in this industry you’ve got to be fairly selective and that’s the hard part. We could hire someone today, but we don’t want to end up with a huge attrition rate and a huge fallout rate where you’re always training new employees. That’s so dangerous, especially from a combined wealth of knowledge of employees.

“If everyone has been doing it for years and years and years, the combined knowledge or combined experience of everyone is that much greater. If 60% of your workforce turns over every six months or a year, you never really accumulate that knowledge.”

Despite those worries, Kill Devil Diesel has been fortunate in the fact that its team has been functioning well, which Jared credits to many of his employees’ backgrounds in Monster Jam and the success of word of mouth recruiting.

“A lot of our employees came from Monster Jam, as did I,” he says. “That gives us a little bit more of a unique, broad and diverse skillset that makes it easy to be flexibile. I’m able to have different guys run different machines or do tear down or machining or assembly. People can float a bit and cover where we’re busy or where we need help.

“We’ve been very fortunate that we have a very good group of guys. They say everything happens for a reason, so some of the other ones who didn’t call, didn’t show up and didn’t work out, hopefully that was for a reason. In hindsight, as bad as we needed them that day, I’m maybe glad that it took a couple weeks longer to find the “right” person. We haven’t gotten rid of anybody. There’s been some learning curves along the way, but we’ve been very fortunate that everyone has worked out.”

Not every shop is as fortunate to have finally come across the right employees for their open positions, and in some cases, those shops just have to keep on operating as is. An example is David’s Machine Shop in Georgia. Owner David Linder has had numerous employees come and go without making much of an impact.

“We haven’t found an avenue to get reliable employees,” says Linder. “After trying all these things, we’ve kind of resorted to the fact that we’re going to just stay a small shop. We’re going to stay four employees and stay six months behind on work.”

Something Alderson is excited about that should have benefits for his own shop employees and potential future employees is a partnership with a local community college.

“The College of the Albemarle school here by us has seen some of the same void that we are experiencing here looking for CNC operators in our area,” Alderson says. “They know there’s opportunities to teach people these skills, so they have a handful of CNC machines there and programs to teach the kids Fusion 360 and Mastercam and manual machining classes. We’re working with them on a two-way partnership to send some of our guys there who maybe know the nuts and bolts, but don’t have any formal machining experience to get formal training. Also, we would love to work with them on an internship at our shop, so we’re trying to fine tune exactly what that program will look like. We’ve been in contact with several graduates or soon-to-be graduates from the program.”

As with any avenue for finding employees, schools aren’t always a sure-fire success. It still depends on the individual and, as stated before, whether they have the proper drive.

“I don’t think it’s the school’s fault,” Linder says. “I think they’ve got the same issue – they’ve got problems finding qualified people to go through their schools. I’ve looked at the knowledge and the technology [available in these schools], and it’s a killer deal. The students who are good at engine building don’t stay in your shop for long. The good ones have all kinds of opportunities.”

No matter what strategies you put in place in an effort to find new employees, just be sure that you cast a wide net and ensure that you find someone who has the desire to be in the shop, no matter what role it may be. That will ultimately be the differentiating factor between a successful employee and the one looking for yet another new job.

“Recruiting is important. Retention is doubly important,” Alderson says. “It’s interesting comparing notes with other people in the industry to try and get affirmation that we’re on the right track or we’re not the anomaly or an outlier when it comes to hiring new employees. Everyone we’ve talked to is trying to hire or has hired and they’re just trying to keep up. It’s been crazy. It really just highlights how important those relationships in the industry really are.” EB