Diesel of the Week is presented by

Building an engine is an investment of not only money, but time. Hours upon hours go into a fully functioning and properly performing engine, along with the occasional blood, sweat and tears. The sacrifices aside, the finished product is almost always worth the work put in.

To some, part of that fulfilling feeling is documenting the process along the way. Tyler Wood is one of those builders. With hours of content posted to his YouTube channel, tons of Instagram posts, and a whopping 5,000 individual pictures of parts, components and build processes, he has more than a few ways to showoff his diesel build to anyone interested.

Wood started his career in the automotive world earlier than most, when he began racing dirt bikes at the ripe age of 4-years-old. Over the course of the next 14 years, he acquired a vast mechanical knowledge from repairing motorcycles and family vehicles with his father. When he was old enough to start driving, he was introduced to the diesel world via his first ever vehicle – an F-250 with a 6.0L Powerstroke engine. He now works as a mechanic at South East Diesel Supply, where he continues to hone his craft.

After a short stint of focusing on street bikes and Cobra Mustangs, Wood stepped back into the diesel realm in the summer of 2019, when he traded his ’03 Cobra for another F-250 King Ranch with a 6.0L Powerstroke.

“I picked the truck up with a ‘built’ engine, which I unfortunately found out wasn’t as built up as I had hoped,” Wood says.

Within a week, he had already torn most of the engine apart to start upgrading it further. The first move was to make some phone calls to SoCal Billet Inc., where Wood ordered an S400 package that included a T4 setup and intercooler pipes along with Warren Diesel 250cc/100% over injectors that replaced the stock 190cc/75% over injectors and turbo.

After installing a heftier 5R110W transmission from Wyse Auto LLC, Wood promptly threw himself into a few races against local drivers. Not long afterward, word began to spread about his Powerstroke nicknamed “Heart Breaker.” The last race resulted in a blown radiator hose, which was later found to be caused by a “catastrophic head gasket failure.”

Fast forward 6-8 months, and Wood finally collected all the parts he needed to fix the bad heads and head gasket failure.

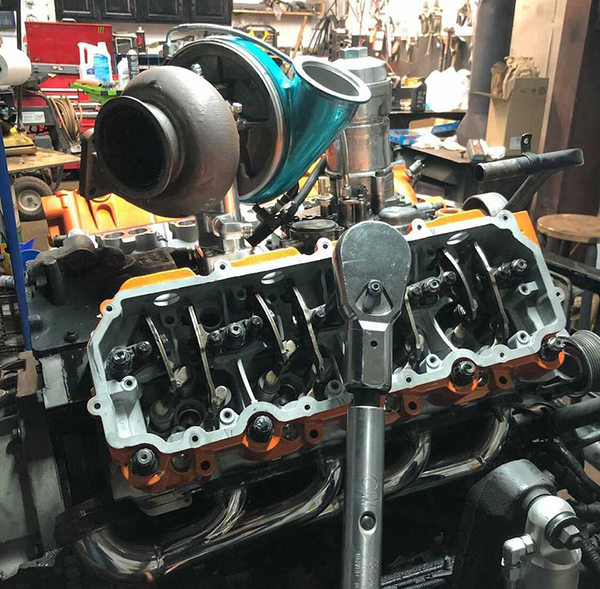

“This is when it got real,” he says. “I realized the head gaskets were in far worse shape than I thought they were in, so I called up Jared Alderson at Kill Devil Diesel and ordered a new set of aluminum O-ring heads. We discussed several specifications and opted to set the valve recession deeper than usual so we could party in the future.”

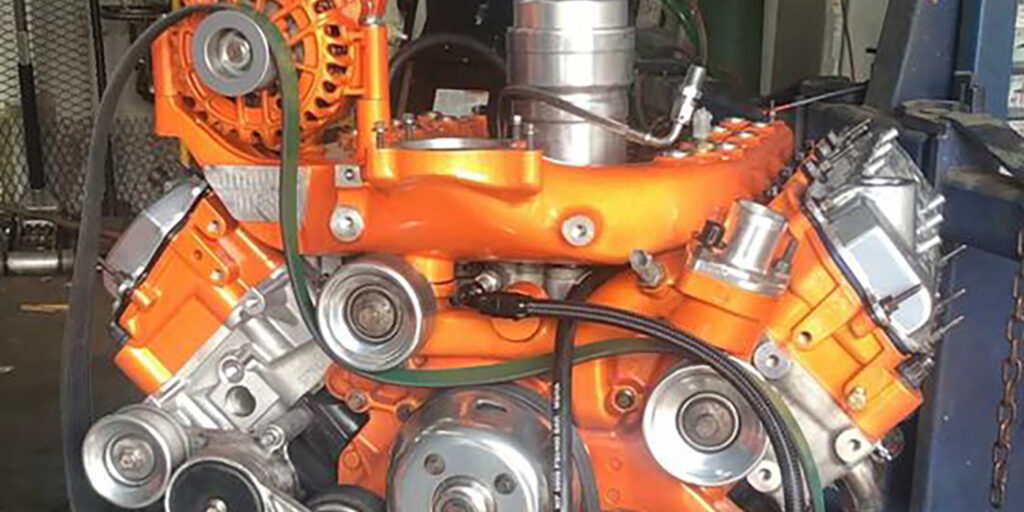

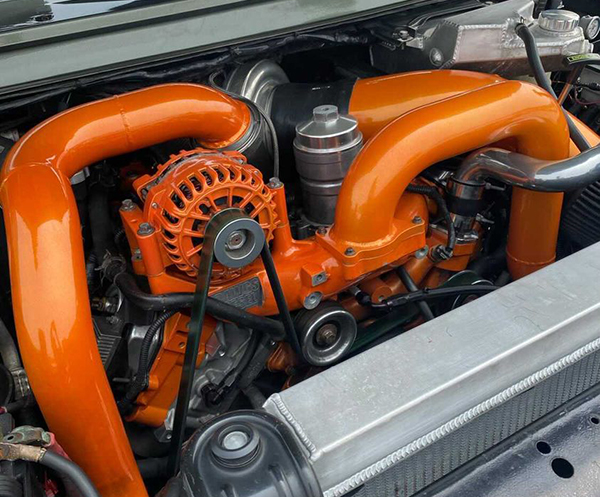

After diagnosing some more issues with the engine, including a seized lifter and premature wear on the main journal and rod bearings, Wood sent the block and bed plate to a local machine shop to be cleaned up and checked for any other discrepancies. Everything in the engine bay was polished, power coated or ceramic coated.

After a few conversations with other members of the diesel industry, a game plan was put together to build a great balance between a street and race truck. He started with ARP main studs after a line bore job and stock bearings were used throughout, along with a Callies Stage 2 crankshaft.

“For hard parts, we elected to utilize the pistons that were originally in the engine with a set of Callies Assassin rods. We didn’t need to do any piston modifications as this was a drop in cam and needed no piston modification to work even with all specs set to a factory standard. Moving up we utilized the aforementioned KDD aluminum O-ring heads along with all factory Ford Motorcraft gaskets.”

On the top end, KDD pushrods and XDP rocker bridges were used. This was all topped off with a new, upgraded set of 350cc/150% over conventional fuel injectors from Warren Diesel. Warren Diesel also provided the high flow standpipes that are paired with a KC Turbo dual HPOP on the oil side.

“Fass Fuel Systems helped update the lift pump with their newly designed pump to help keep the beast fed with enough fuel to make the power we were looking for and keep it quiet,” Wood says.

The 220gph lift pump offers advanced filtration benefits like Fass’ patented air/vapor removal process, which effectively extends the life of the diesel injectors. Powerstrokes are widely known for having injector failures, making this addition a wise one. Nomex braided fuel lines and an XDP sump and regulated return round out the fuel system.

The single turbo air setup consists of a Forced Inductions S476/87/1.0 T4 and an Odawg S3R intake manifold that’s port-matched to the heads, and a Young’s Fabrication 5” cold air intake. Other additions include a Mishimoto intercooler and radiator.

All in all, Heart Breaker makes just shy of 1,000 horsepower. With a weight of 6,900 lbs., Tyler was still able to make a respectable pass of 7.14 @ 96 mph in the 1/8th mile. While the truck is both a beast on the road and the track, Wood has plans to do more soon.

“Ironically enough I’m still unsatisfied and want more,” he admits. “Currently there are plans in place to ditch the HEUI injection and move to common rail. That will be a huge factor in making more power and being streetable at those higher power levels.”

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].