Diesel of the Week is presented by

Well, we’ve officially seen it all in terms of engine swaps. On April 1 this year, we stumbled upon an Instagram post that detailed a “plan so outrageous, it had to be shared on April Fools’ day because no one would believe it.” That plan was to stuff a 6.0L Powerstroke under the hood of Nissan’s legendary GT-R and drive it in “The Race to the Clouds” – the Pikes Peak International Hill Climb. That’s not all. The even loftier goal was to make the fastest diesel-powered run in Pikes Peak history.

Unfortunately, oil pressure issues led to the 2010 R35 GT-R ending the event earlier than desired. However, driver Cole Powelson did pilot the diesel Nissan through the first section in a time of 2:15.061, only around five seconds off the pace of the record set by Scott Birdsall and ninth fastest overall through the section in the Unlimited class.

We think that’s pretty impressive given the uniqueness and unusual pairing of the build, and the silver lining to the team’s setback is, Pikes Peak will always be there next year. In fact, the team is already planning out an attack.

The Powerstroke GT-R was a joint project between the likes of Lyfe Motorsport, which specializes in motorsports design, engineering, construction, operations, and professional racecar builds, and Riff Raff Diesel, a Powerstroke-focused manufacturing and retail business. The two came together when Lyfe Motorsport owner Cole Powelson had a unique idea for the race team’s pride and joy GT-R.

Lyfe originally purchased the car from Cobb Tuning who campaigned it as their time attack car in 2010. By 2013, Lyfe Motorsport became the first race team to win a North American endurance race in a non-factory-built GT-R. Then in 2015, the car would be retired for almost 6 years following a crash at Pikes Peak. In 2021, Powelson got the idea to restore the car to its former glory and call on Riff Raff Diesel for help with a powerplant.

“This is actually the second project we’ve done with them,” Powelson says. “We did a ‘55 Ford F-100 that we put the same 6.0L engine into. We finished that project and I drove it and I was like, ‘Damn, this thing actually boogies.’ It’s a pretty good engine. We joked about putting a 6.0L in a GT-R, and that joke just became more serious.”

How can a 2004 6.0L turbo diesel V8 compare to the VR38DETT that was originally under the hood? Surprisingly, the numbers aren’t so far off. The VR38DETT was bored out to 4.0L and force fed by twin Garrett GTX3076 turbos; on the dyno it made around 1,200 horsepower. Although the official numbers were never released, the Powerstroke made in the neighborhood of 850-950 horsepower and well over 1,000 ft.-lbs. of torque – and that’s on fuel alone, before nitrous enters the equation.

While the car is heavy for a GT-R (north of 4,000 lbs.), that’s still relatively low compared to other diesel-powered vehicles.

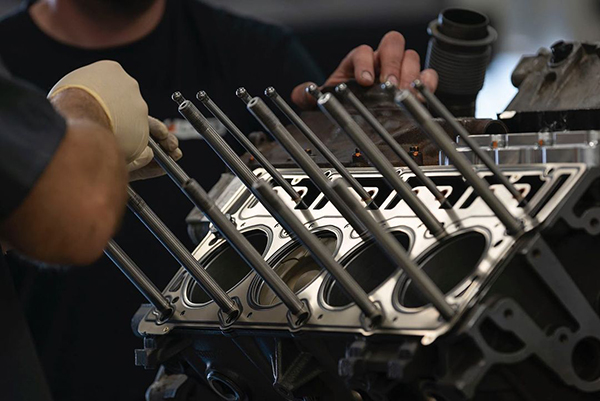

The factory block is fitted with a set of Mahle stock-bore, ceramic-coated pistons with valve reliefs cut in. The valves are operated by a Stage 2 billet camshaft, and it hits the Anderson HS lifters using Smith Brothers pushrods. A set of ARP 625+ head studs contain the heads and the valvetrain is covered by Riff Raff Diesel billet valve covers.

Fueling this setup is a set of 250cc 100% injectors and a compound turbocharger setup with a KC Turbo Jetfire Stage 1 as the primary and a BorgWarner 80mm atmosphere turbo working as the secondary to force air into the ODawg 6.4L inverted intake manifold. The intake system is so massive that its tubing is mounted inside the cabin, directly in front of Powelson.

A water sprayer is added in front of the intercooler to assist with keeping the charger air cool, making up for the lack of air as the car climbs in altitude up Pikes Peak. The Powerstroke engine is oiled thanks to a Terminator T500 high-pressure oil pump feeding 10w40 diesel oil. This is sent through a custom dry sump system that required the use of a Kill Devil Diesel dry sump front cover and custom-made oil pan.

The engine system is kept cool by using custom, rear-mounted radiators. But, even with the large radiator and custom ducting to feed air across it, the cooling becomes less efficient the higher you go on the mountain. To fix this, the Lyfe team also utilized a large water/ice tank to help cool the car.

Behind the 6.0L Powerstroke is a John Wood custom 4R100 four-speed automatic transmission, a step away from the AWD transmission that was originally used.

“We made plenty of power, but there were some other things that needed to be sorted out on the run, especially on the oil control side of things,” Powelson says. “With the amount of wide-open throttle time you spend and the high cornering forces, there’s just a lot to figure out with these engines.

“The oil system parts we used were good for a 10-second drag run, but they just weren’t up to the task for an 11-minute run up Pikes Peak at a hard pace. For next year, we’re keeping the turbo system and all that, but the oil system will get completely revamped to improve reliability.”

We’re excited to see where the Lyfe Motorsport team and Riff Raff Diesel are with the build by next year’s Pikes Peak, and we’ll definitely be following their progress closely.

If you’re interested in following this diesel-powered 2010 R35 GT-R build from start to finish, check out the Lyfe Motorsport YouTube Channel for the complete 10-part series.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].