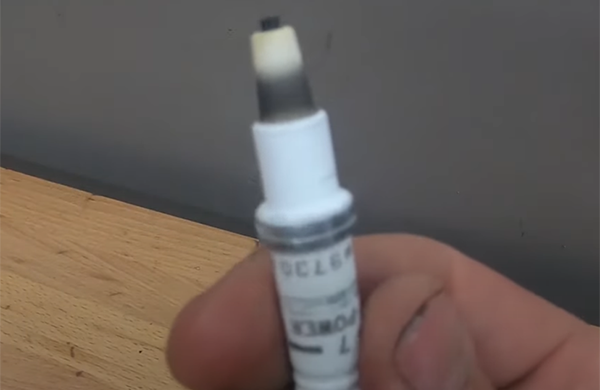

There are a lot of tools and sensors today that can aid you in understanding what’s going on in your engine and how to make adjustments. However, I’m here to tell you that you can learn a lot from reading your spark plug(s). I don’t care what your O2 says. I don’t care what your EGT says. I don’t care what your fuel flow sensor says. I don’t care what your mom says, your dad says, your daughter says – I don’t care what anybody says. What tells you the most amount of information about what’s going on with your engine is the spark plug, period.

That said, you have to know what you’re looking at and what that spark plug is telling you in order for the spark plug to be an effective tool in tuning your engine. And that’s what I’m going to walk you through. Now, it’s a good thing to have O2 sensors. It’s a good thing to have as much information as you can, but they’re just numbers and reference numbers. Those reference numbers are helping you tune, but the be all and end all is always the spark plug.

To demonstrate how to properly read your spark plug(s), I’ve actually cut the spark plug apart. There are some companies out there that make a spark plug cutter, so you can actually do that and pull them apart and take a look at it. Personally, I cut my spark plug apart on a lathe.

The first thing I want you to look at on the spark plug is the porcelain (Photo A). Now, what you’re looking at the porcelain for at all times is for a rich/lean condition. People think if they see white on the porcelain that there must be something wrong. Absolutely not. As a matter of fact, this spark plug is actually rich.

This is rich because you can see this black line is about middle of the way up the porcelain. If this was in a really sweet spot, typically you would be at about a hundred thousandths from the bottom ledge of the spark plug. You’d have a really sharp, nice, crisp line about where my thumbnail is in the photo in photo B.

The richer the engine is, or the more fuel it has in it, the farther up that black line is – it keeps on going and going and going. If it was all the way up to the top, it’s just pig fat rich, and that just means you’re way down on horsepower. The spark plug shown here is probably between 5% and 10% too rich, so I would probably start leaning that up to watch that black ring go down.

Now, I can do this type of testing on the dyno because I can make a pull, shut off the engine and then take a look at the spark plug. You need to do the same thing at the drag strip or wherever you’re at, but you can’t just idle. You can’t idle because as you idle the engine, it pollutes and contaminates the spark plug because the idle is always running different. Keep that in mind.

The bottom line when it comes to the porcelain is that the farther up the porcelain that black ring goes, the richer the engine is running, and the farther down that ring goes, the leaner the engine is running. You want to have about .100” of a ring showing. If there’s no ring there at all and you can’t see anything other than just pure white, your lean, and your O2 sensor and gas is probably going to say you 14:1 or 15:1 – something like that. But, remember, those are just reference numbers – the spark plug tells you everything.

While the porcelain gives you insight to whether you have a rich/lean condition, the strap of the spark plug gives you information about your timing (Photo C). If you have way too much timing in something, such as in a nitrous motor for example, it’ll start nibbling that top edge of those straps up, or it’ll burn the straps right off (Photo D). That definitely is from having too much timing, which ends up being pre ignition, detonation, etc.

What you want to see on this strap, like the spark plug porcelain, is this strap having burned color all the way down to the bottom edge of the strap (Photo E). That is typically a nice, sweet spot safe for max timing. If it has too much timing in it, it’ll start burning all the way down into the base thread of the spark plug and you’ll see that burned color too far down. If you get beyond that, that’s when you’ll start to see the end of the strap get nibbled up or burned off completely, as mentioned earlier.

If you don’t have enough timing in it, you’ll actually see the (burned color) black line moving up the bend of the strap (Photo F). If it has a black line at the middle of that bend, you’re probably short timing like 2-4 degrees. If it has no heat in it and it’s just barely burned clean near the tip of the strap, then we definitely know you’re way short on timing. You probably need to put a lot of timing back in it.

As you add timing to it, this strap is going to burn cleaner, cleaner, cleaner, and cleaner. Typically, right at the base of that strap is a really good, safe spot for peak torque and peak horsepower (Photo G).

With those two important elements explained, I’ll leave you with this number one rule in engine tuning. If your tuner doesn’t look at a spark plug, he’s not a tuner, he’s just a computer guy. You need to look at spark plugs. You need to understand what’s going on in a combustion chamber and how to read what the engine is telling you through the spark plug. If you can master that, you’ll keep your engine happy. EB