A Horsepower Love Story

When it comes to Subaru engines, even given some inherent design flaws with respect to their weaknesses, they are still and always will remain legendary Japanese tuning platforms. These engines make easy power, are well-known and available, and are great options for a number of performance-oriented applications, but at a cost.

In today’s world of cheap horsepower with the aid of power adders such as nitrous, turbos and blowers, it is becoming easier and easier for car enthusiasts to make some serious horsepower numbers. In fact, 500, 600, even 700 horsepower is almost becoming the norm in the street car world, let alone the race car world. With all of this affordable power becoming easily available, reliability is another part of the equation often overlooked.

Given the options of power, price and reliability, you typically could get two out of the three in years past. Want power at a low cost? Reliability will become your issue. Want it built for power and reliability? That’s going to hit your wallet harder… or is it? Enter the world of block conversions – aka block filling.

Block filling with concrete or epoxy block fillers was a cheap alternative for the weekend racer because it worked. However, they sacrificed some drivability due to less coolant capacity from being filled with some hard and tough substances. CNC closed-deck block conversions on the other hand, offer a better solution.

Let’s dive into all the reasons why you should consider getting a closed-deck block conversion as opposed to your open-deck block.

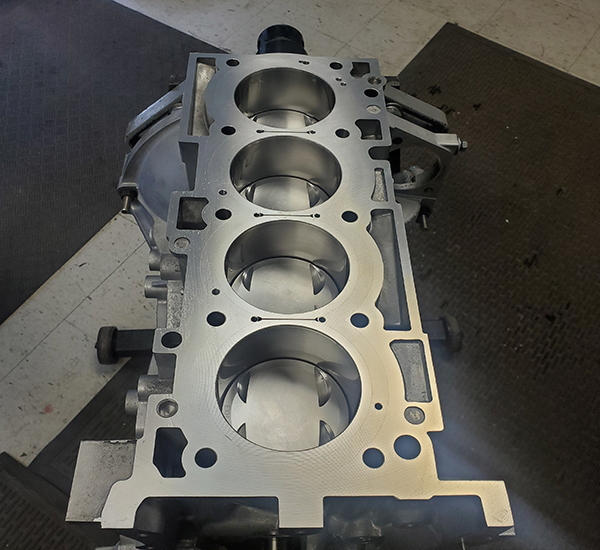

First of all, open deck blocks are weak – plain and simple. Yes, they offer all the cylinders to be fully surrounded by coolant to keep some heat down, but that open-deck block is not supported and will often shift around, leak at the head gasket, or worse yet, crack – leaving you with any number of serious engine issues. What do you do to prevent those issues?

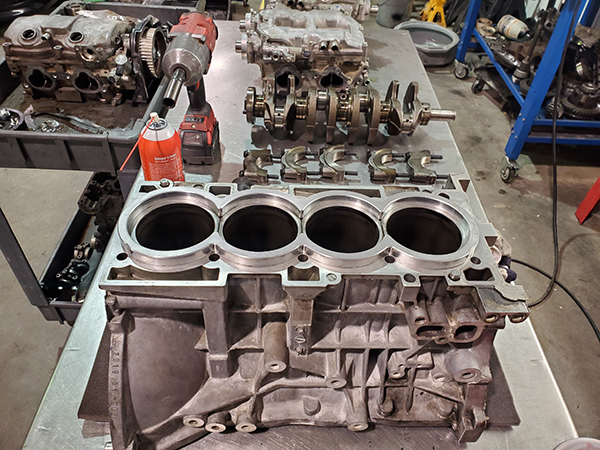

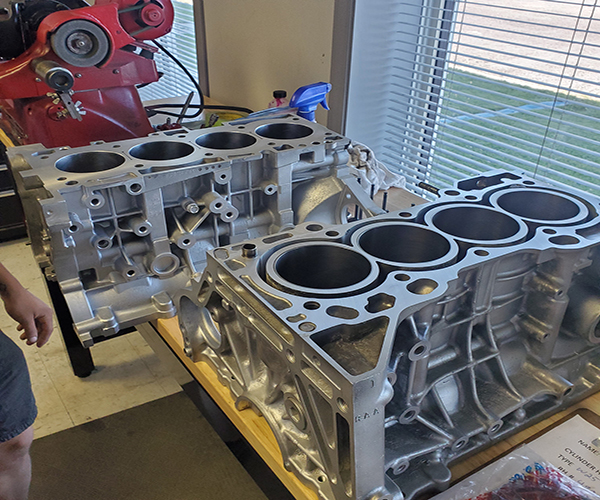

You get a CNC closed-deck block conversion. Most of the time, customers are building up Subaru engines for street car, drag racing or road racing applications, and if customers want to find a lot of power, Nemesis Performance addresses an inherent weakness in the structure of the cylinder blocks.

We put it on our Haas CNC and we actually machine what is called a closed-deck block. Basically, the cylinders and what supports them in the block is only held together by four little tabs. As boost increases and horsepower increases along with the harmonics that come with horsepower, they will actually crack the cylinder liner. That block now needs to be repaired and needs sleeves.

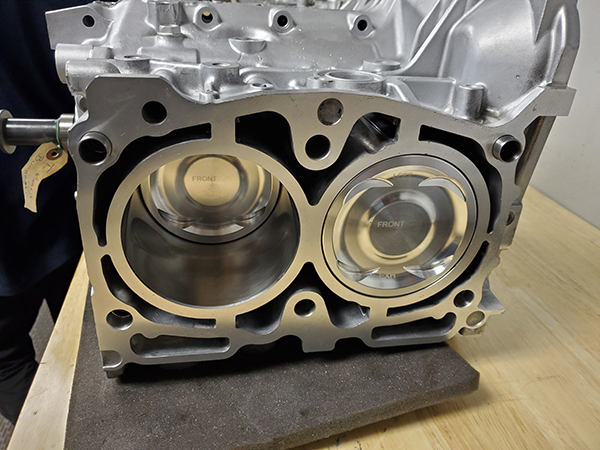

We’ve adopted the philosophy of scanning the block into a CAD. We’ve designed these inserts that get machined. The block gets machined and the inserts get pressed in and effectively close the upper deck of the block and supports the cylinder structure right where it’s required, which is usually right where all the combustion force is happening in the first half-inch of the block.

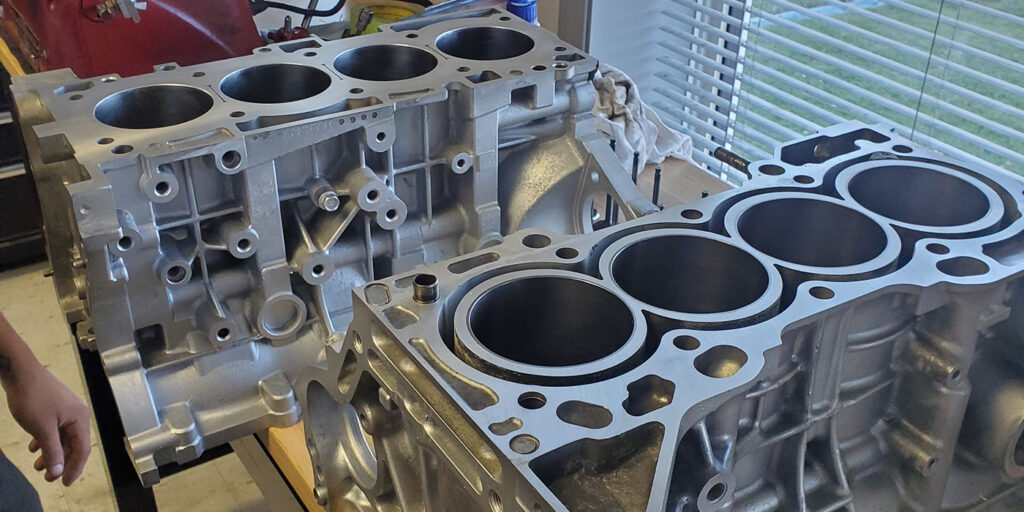

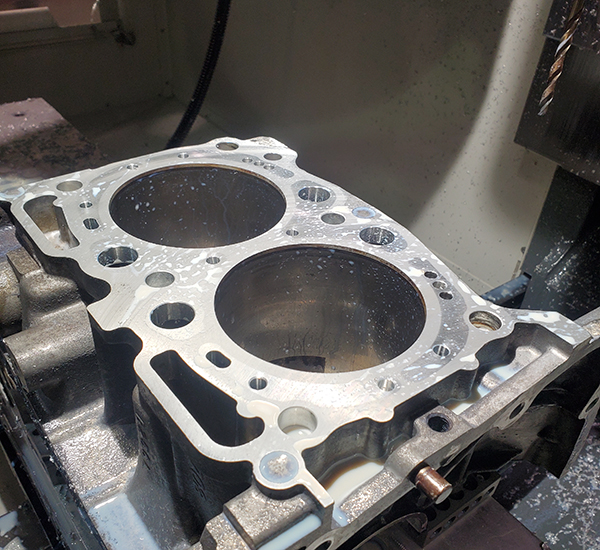

To create a closed-deck block conversion, the block is mounted and dialed in on a CNC machine and is cut around the cylinders and water jackets, leaving a register (ledge) that is often .500˝ deep. Once the block is cut, the reverse (a plug) is also cut out of solid aluminum. Today’s CNCs being accurate to thousandths of an inch makes easy work of this.

Once fully cleaned and prepped, the inserts/plugs are pressed into the upper portion of the block until they rest on the register. This will prevent the inserts from dropping further into the block. When installation of the inserts is complete, the block will get further processing such as coolant ports machined into the deck, decking the mating surface, as well as a bore and hone.

Now, what you are left with is a fully closed-deck engine block that offers numerous benefits over your previously weak open-deck block. Not only does it create a more robust engine, but you have a significantly increased clamping surface for the head gasket, which is another inherent problem of Subarus. You’re getting the best of both worlds. You’ve got more surface area to clamp the head gasket and keep its integrity intact, as well as keeping the rigidity and supporting the cylinders from moving and cracking.

That structural rigidity and support due to the inserts will also help with engine harmonics for starters, but it raises the engine’s capacity for elevated cylinder pressures too. The billet supports being .500˝ deep are adding strength right at the upper portion of the cylinder where most of the cylinder pressures are realized. This helps prevent cylinders walking, or worse, getting out of round – otherwise known as ovaling.

While open-deck blocks offer good cooling aspects, cooling is not an issue in a closed-deck block because the coolant that flows to the head is still passing through a small galley that matches the port holes in the head gasket. This was the restriction of coolant flow prior. The billet supports are also helping to draw the heat away from the upper portion of the cylinders as well.

Next, we have a significantly increased clamping surface area on the upper deck of the engine, which lends itself well to where there was an absence of support material in the cylinder’s coolant cavity. This increase of clamping surface area is a drastic improvement for maintaining head gasket integrity. More cylinder pressure equals more power and now this engine block is ready for both.

If a customer desires to go north of 500 horsepower or in excess of 30-lbs. of boost, a closed-deck block is a requirement for added protection. That’s not to say you can’t do it without this modification, but you’re really pushing the limits of everything in that engine at that level. The upgrades we look at performing at those horsepower levels are in oiling, hypereutectic pistons instead of forged and the deck architecture of the block itself.

The next time you’re considering power, price and reliability, remember, you can have it all.