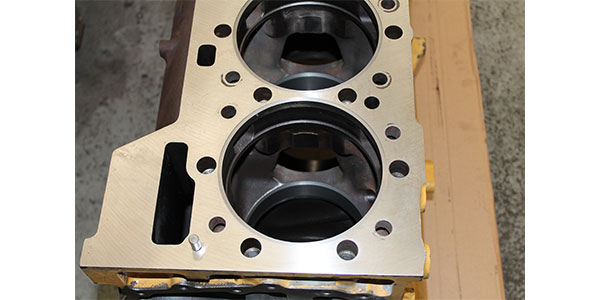

Press Fitting Cylinder Sleeves

There’s something extremely satisfying about a good sleeve job on an engine. There’s also a number of ways sleeves can be installed, so Jeff McCord of LinCo Diesel Performance shows you the way his shop does it and how it helps in high-horsepower diesel applications.

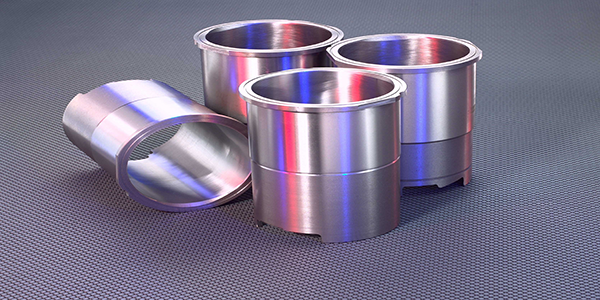

Inside PowerBore Cylinder Sleeves

Engine Builder gives you an inside look at PowerBore Cylinder Sleeves’ Salem, OH manufacturing facility. See the process PowerBore uses to manufacture its sleeves and install them into an engine. For more information: PowerBore Cylinder Sleeves

Circling the Potential of Cylinder Sleeves and Liners

What do cylinder sleeves and a certain rodentary rock band from the ‘80s have in common? You guessed it, the shape. But we’re going to leave the rockin’ to the hair guys and the talkin’ to the car guys, so for the sake of this article, we’ll just be covering the first one.

Cylinder Sleeves – Not Sexy, but Necessary

Sleeve installation continues to be a solid market for engine builders and machine shops Sleeving – at its crudest definition – is fixing a round hole. However, you better believe there is much more than that going on, and the opportunity for engine builders and machine shops to make money is tremendous. Whether a block

PowerBore Cylinder Sleeves Power Ductile Material

PowerBore Cylinder Sleeves has introduced its new Power Ductile material. After months of research and sampling, PowerBore has created a ductile iron chemistry with significantly enhanced mechanical properties, well beyond what is common in the standard grade ductile iron that is used in most performance cylinder sleeve applications. “Power Ductile is truly a premier ductile

DARTON SLEEVES: How Cylinder Sleeves are Produced

Darton International was incorporated in 1978 with a goal of becoming a premier manufacturer of automotive speed equipment parts. In pursuit of this objective lead the founders to establish manufacturing relationships with unique European factories specializing in products and techniques which would harmonize with Darton’s potential customers. Darton initially selected two groups of products to

Cylinder Sleeves and Liners

Iron sleeves provide a wear-resistant surface for the piston rings, and they don’t have to be very thick because they are supported by the surrounding block. Cast iron blocks, by comparison, don’t need cylinder sleeves because the iron is hard enough to resist ring wear. If a cylinder is cracked, damaged or worn to the

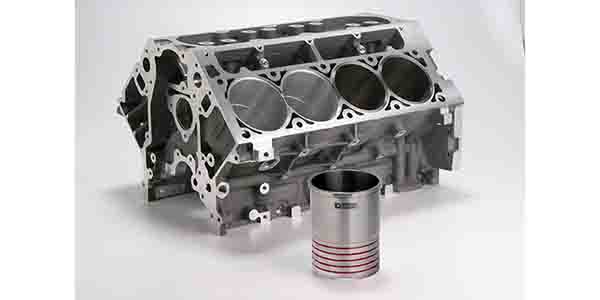

Engine Blocks & Cylinder Sleeves

In our February 2009 issue, Technical Editor Larry Carley provided a comprehensive overview of the changes in engine blocks over the years. Thanks in part to natural attrition (after all, many of the most popular engines were actually designed and built more than 50 years ago) and the high price for scrap metal in the

Performance Cylinder Sleeves

In the performance segment of the automotive aftermarket, young enthusiasts often think only the latest is great enough for their vehicle. Thanks to the prevalence of computerized engine management systems, some might believe that high-tech guarantees high horsepower. Yesterday’s technology? No way will it find success on the street or strip. However, engine builders know

Darton Sleeves’ Seal Tight Sleeve Kits

Darton’s sleeve kit maximizes fitment and installation ease.

Installing Flanged Sleeves in a Cummins Block

Jeff McCord at LinCo Diesel Performance walks you through the necessary steps for properly sleeving a block. It might sound like a simple process, but any errors can mean catastrophic head failure down the road.

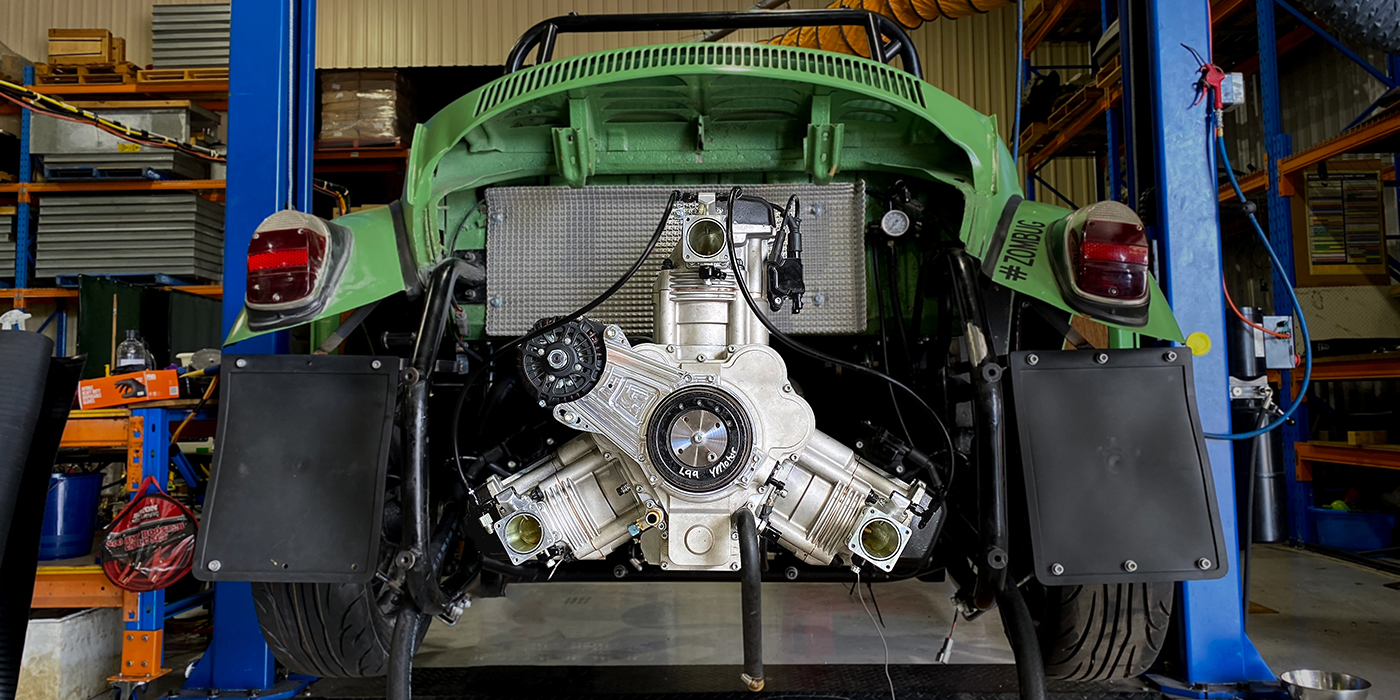

Radial Motion’s 3-Cylinder Compact Radial Engine

Radial Motion’s three-cylinder compact radial engine is a four-stroke gas engine in a 120° radial configuration. Lightweight and compact, the 2.0L and 2.1L engines deliver both performance and reliability with unique visual appeal and an emotive exhaust note. The engine is capable of withstanding high cylinder pressures, making it well suited for turbocharging and supercharging. Check it out!

Piston Rings, Oil & Cylinder Wall Finish

A piston ring package is not only a seal for compression, it’s also controlling and distributing the oil on the cylinder walls of the block. The way a ring interacts with oil and the bore finish is critical to engine efficiency.

Melling Cylinder Sleeve 2018 Catalog

An updated Melling Cylinder Sleeve Catalog is now available for download on the Melling website.

Sleeves and Liners – Metallurgic Magic

Dry sleeves and wet liners have long been used to repair and restore cracked or worn engine cylinders, but they are also used to reinforce aluminum blocks that are being built for serious performance applications.

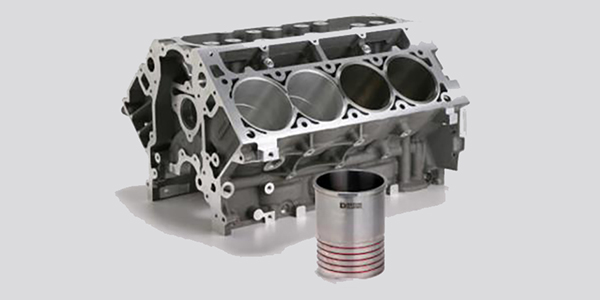

Katech Introduces ‘Sleeved’ LT1 Cylinder Block

Katech’s new “sleeved” LT1 cylinder block supports greater displacement Gen V LT1 engines and serves as the foundation for 427-cubic-inch (7.0L) engine combinations.

Sleeves & Liners – Selection and Installation

Engine sleeves have long been used to repair worn or cracked cylinders that can’t be bored to oversize. Installing a sleeve can save a block that would otherwise be unrebuildable. But sleeves can also be used to strengthen cylinders, especially in performance engines that are being pushed way beyond their original design tolerances. A prime

Custom Cylinder Sleeve Manufacturing by Melling

Melling Cylinder Sleeves in Maquoketa, IA can manufacture a custom sleeve for your application.

Liners and Sleeves

Sleeves are certainly not new technology and experts say that, for the most part, engine builders and machine shops understand the use and functionality well. But is a liner and a sleeve the same thing? Is a hole just a hole? Publisher/Editor Doug Kaufman takes a deeper dive.