Valve Timing Events and the Order of Importance

If you’ll recall, in the January issue, we got into the nitty gritty details of what makes a camshaft the “right” camshaft. In this issue, we’ll continue the education. Cam class is back in session!

High-Tech Tightening

When you build your engines, you put measured thought into every component you use. From the intake system to the exhaust manifold, everything has its place and nothing is installed without careful consideration. But what about the fasteners? Some of the most critical components are held together with relatively low-cost fasteners including screws, nuts and bolts and studs.

How to Find and Fix Cracks

Cracks are bad news because they never heal themselves. Once a crack starts, it always gets worse. Checking critical engine parts and castings is time well spent if it heads off a major problem that might result in a major engine issue or a warranty claim.

A Hell of a Good Year

The folks at Dougans Racing Engines won a lot in 2015. A banner year, according to Ray Field, owner of Dougans. It was this success coupled with the shop’s rich history that helped Dougans’ nomination get selected as the 2015 Performance Engine Builder of the Year, sponsored by Speed-Pro POWERFORGED Pistons and Engine Builder magazine.

Going Faster in 1954

I have a large library in my office consisting of Hot Rod How-to books and annuals from the 1940s, ‘50s and ‘60s. During one of my recent review sessions I found a chapter introducing nitromethane and its use for drag racing. Keep in mind this is 1954 technology…

Shop Solutions March 2016

When vacuum checking 4-valve-per-cylinder heads, it’s hard to tell if it’s both or just one valve that’s leaking. Use your vacuum tester and one of those long inexpensive BBQ or candlestick lighters. Hold the lighter close to the valves and the leaking vacuum will pull the flame in, making it easy to tell which one is leaking.

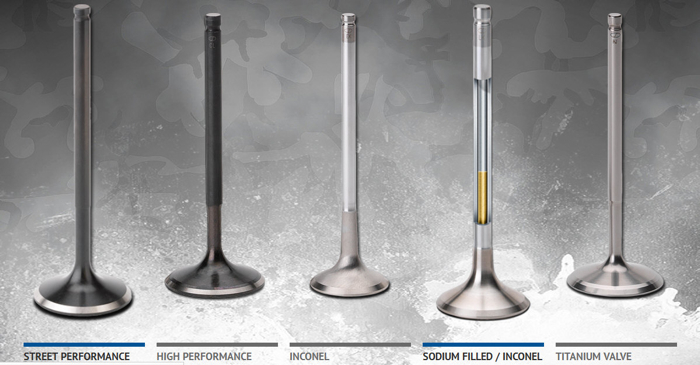

Valves and Seats

The valves and seats in an internal combustion engine play a central role in engine breathing, compression, performance and longevity. It doesn’t matter if an engine has two, three, four or even five valves per cylinder or if the engine is gas or diesel because the valves all do the same thing: they open and close to allow air into the cylinders and exhaust to exit the cylinders.

How Today’s Wake Surfing Craze Can Be Killing Marine Engines

According to some experts, wake surfing has become one of America’s hottest sports. For those of you who are actively involved in building engines for pavement or off-road racing, marine motors may seem to be either an obstacle or an opportunity – and you would be right in both cases.

Revved Up – Why the Import Engine Market is on the Rise

For numerous reasons in recent years people have been fixing engine issues rather than replacing engines altogether, making for a strong outlook in the import engine market. There are several ways you can break into this market or improve your stance here if you’re already an import engine builder.

Pistons and Rings – The Technical Price for Horsepower

One of the most overlooked components of the internal combustion engine is the piston ring. It is, by scale, one of the hardest working components in the engine. And when you are building an engine, before choosing your piston rings you have to determine your application.

Understanding How to Tune Carburetors

An engine only runs as well as it is tuned. You can build a killer motor using all the best parts and machine and assemble everything with the utmost care, but if it’s a carbureted engine and the carburetor isn’t set up or tuned right your killer engine may never live up to its full potential.

The Daily Grind

Today, seats are made of a wide variety of materials, different combinations of various alloys, powdered metals and other super hard materials. This seat material is designed to prolong the ability of the valve seat to seal against the pounding of the valve head during engine operation. The variety of materials also means new and different abrasives are required for proper machining.