Replacing Crankshafts, Connecting Rods and Bearings

The crankshaft, connecting rods and bearings are extremely important in every engine build, whether mild or wild, because they convert the reciprocating motion of the pistons into rotational torque. The longer the stroke, the greater the leverage effect and the greater the torque output of the engine. There are three things that need to be

Building Performance Cummins Engines

The clouds of black smoke along with the whistling of the turbo bring out a new wave of spectators. It’s all about the rumble and feel from the massive foot pounds of torque, not the horsepower. Who would have ever thought that a diesel engine would gain respect in the world of performance? Now, it’s

Engine Builder Shop Solutions May 2014

Plastic Fantastic For many years, bolt boots have been the primary way to protect the crankshaft journal from damage during piston installation. Some shop supply companies sell long steel tubes that serve as guides to help align the rod to the journal. These help align the rod, but can also damage the journal surface. For

April Engine Builder Shop Solutions

Combustion Chamber Molds When making chamber molds for a variety of purposes, including holding up the valves on the assembly bench, (as opposed to a beanbag or shop rag) common auto body filler (Bondo) works very well. It’s fast and very inexpensive. Just mix the body filler and fill chambers of an assembled head. The

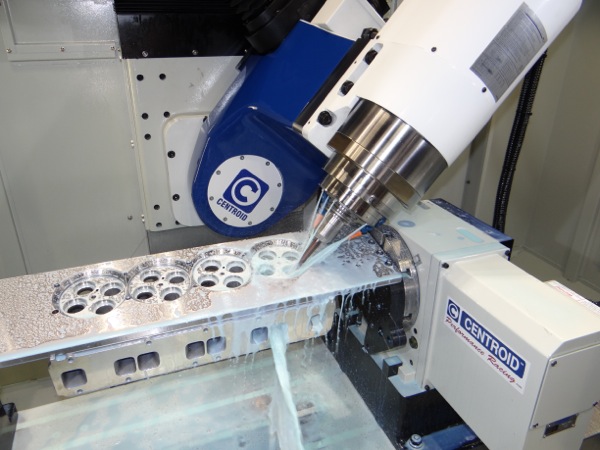

What Can CNC Do For You?

Are you using Computer Numeric Controlled (CNC) equipment in your shop? According to our most recent Babcox Machine Shop Market Profile Survey, 12 percent of engine builders said they own a CNC machining center (a multi-purpose machine that can do surfacing, boring, milling, drilling, etc.). The survey also asked what other types of equipment our

Ford’s Mustang Celebrates 50-Year Milestone

We live in some pretty exciting times for performance automobiles, especially muscle cars. Corvettes are taking on the super cars and knocking on the 200 mph door. The Camaro and the Challenger are back and Ford Motor Company is set to celebrate the 50th anniversary of their very popular Mustang. Besides the Corvette, I can’t

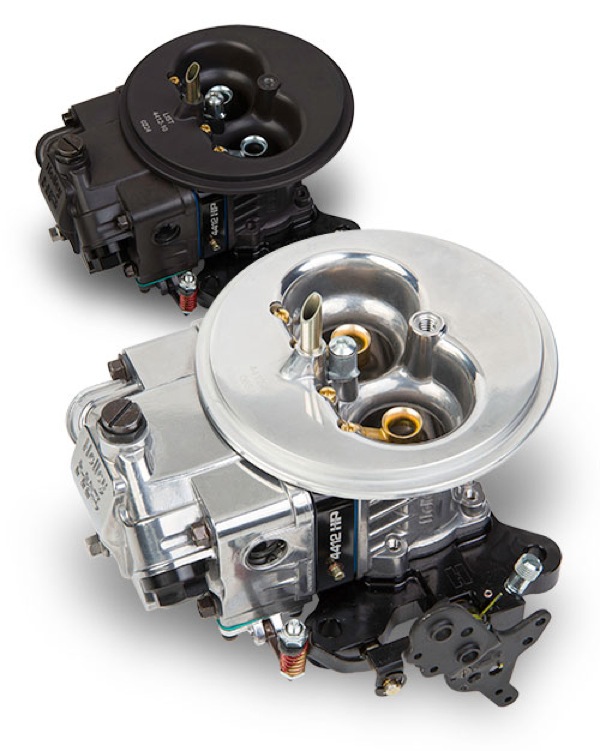

Two Barrel Ultra Holley Performance Carburetor

Holley 2 barrel carburetors have been a mainstay in oval track racing for decades, but racers always want more. They want more tuning ability, more durability, more weight savings and more features, so Holley listened and designed the all new Ultra HP 2 barrel carburetor. The new carb delivers the proven results of the Ultra HP

Growing a Reputation in the Dirt

For late-model stock car engine builders back in the day, it was a different time and a different place. During the 1960s and up until the late 1970s, there were no professional engine builders where a race-ready motor could be purchased. Just ask Morgan Chandler, an inductee of the National Dirt Late Model (NDLM) Hall

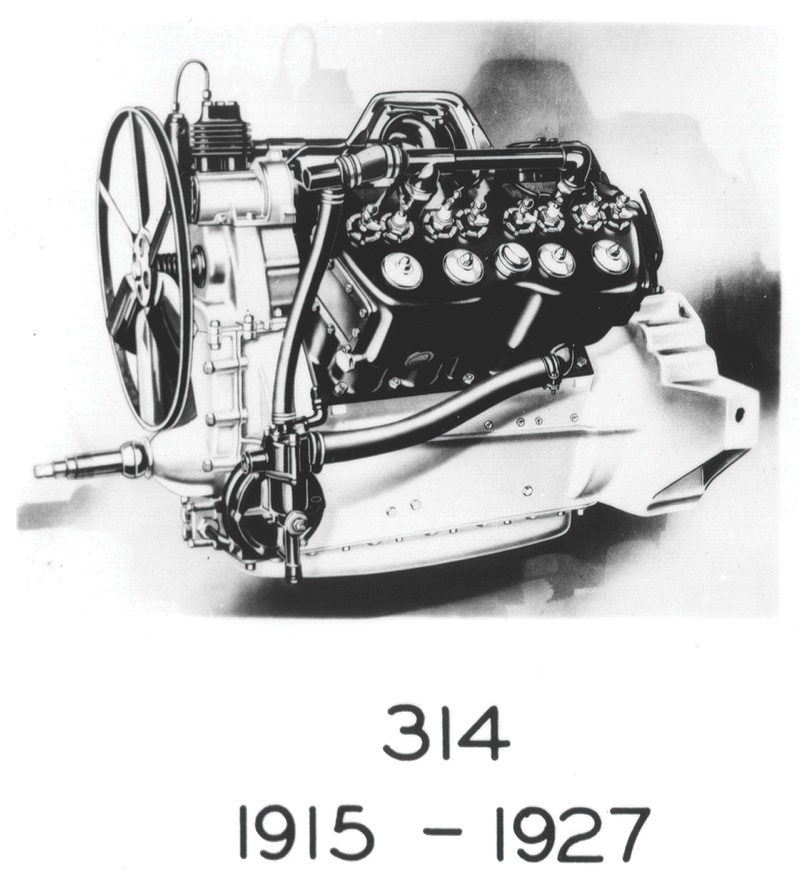

Vintage V8s: Exploring 100 Years of Cadillac Engines

For more than a century, the name Cadillac has been synonymous with performance, style and passion. And in those early years of the Cadillac Automobile Company, it was a former loom mechanic – Henry Martyn Leland – who was credited with forging the technologies that separated Cadillac from the other automobile businesses that were springing

AERA Tech & Skills Conference Hosted by Liberty Engine Parts

Time is running out to register for the AERA Tech & Skills Conference hosted by Liberty Engine Parts on Saturday, March 15, 2014 in Louisville, KY. The AERA Tech & Skills Conference hosted by Liberty Engine Parts will be held at 3865 Produce Road Suite 213-A, Louisville, KY 40218. FEES: $10 per person ($10 for each additional person from the same

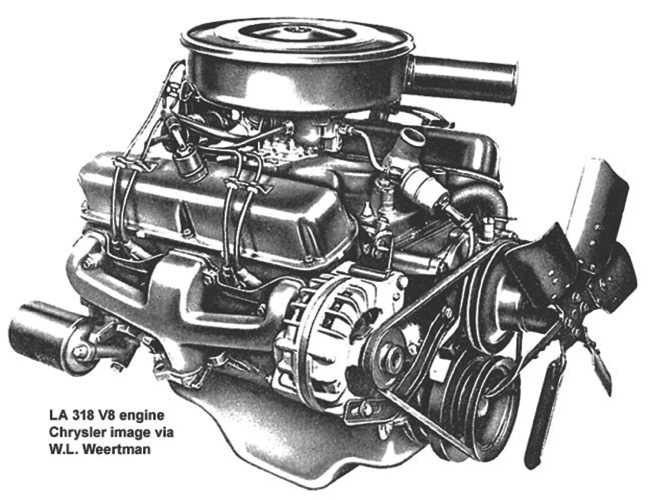

Building a 392 Magnum for the Independence Fund

Ever since the column I did in about stroker motors a few years ago (“Love the One You’re With,” Engine Builder, March 2010), the idea of building one of these engines, a less than everyday stroker combination, has been on my mind. To recap, the premise of the article was simple — Look at the

November Issue Engine Builder Shop Solutions

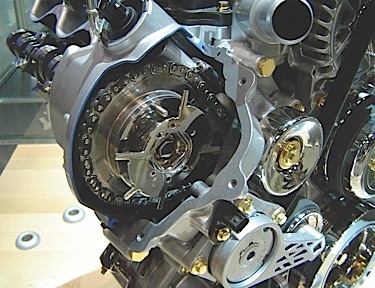

Jeep 3.8L Oil Pressure Problem Many late model 3.8L Jeep engines are losing oil pressure at the oil pump due to failure of the bypass valve. This results in destruction of not only the crankshaft, but the connecting rods. To fix the problem, you need to find the bypass valve inside the plastic timing cover.

Handling Stress Fractures

Salvaging Cracked or Flawed Engine Parts through Detection and Repairs Cracks are often blamed as the cause of a head failure. In many instances, the cracks are not the cause of the failure, but a symptom of another underlying problem such as overheating, detonation or incorrect installation (wrong torque on head bolts, dirty bolt threads,

Quieting Down Chrysler’s Versatile 3.3L And 3.8L Engines

These engines have a mixed reputation for being high-mileage, dependable powerplants as well as noisy motors that can fail at relatively low mileage. First introduced as a family back in 1990, these engines have been upgraded and improved to provide good torque for the necessary applications, reasonable fuel economy and a reputation for durability and

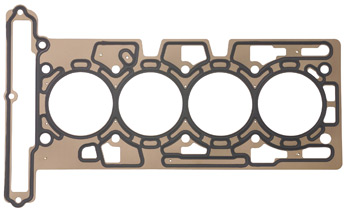

Head Gasket Q & A

Cylinder head gasket design has become more sophisticated than in years past. The following FAQs on head gaskets may give you a better understanding of WHY you need to rebuild a particular engine. Can an overheating motor cause a head gasket failure? One reason head gaskets fail is because of engine overheating. If the engine

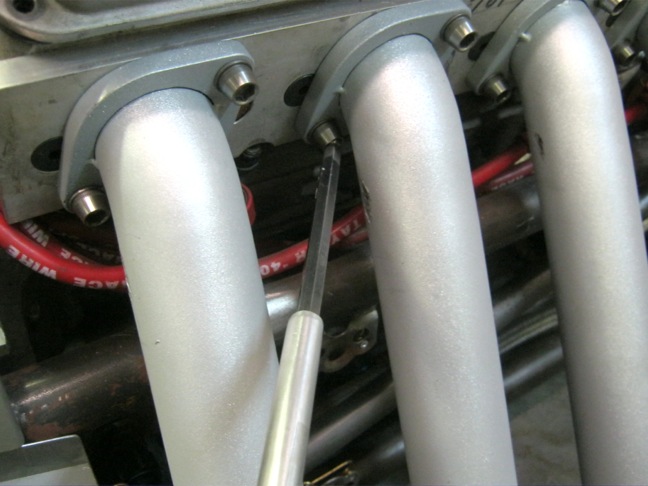

Service Issues on Ford 4.6L SOHC & DOHC Engines

In 2005, Ford introduced a three-valve (3V) SOHC version of the 4.6L for the newly restyled retro-look Mustang. Major changes included the use of two intake valves and one exhaust valve per cylinder to increase air velocity, torque and power, variable cam timing and a weight-saving aluminum cylinder block. Ford’s overhead cam 4.6L V8 engine has been

Engine Builder Shop Solutions: August 2013

Authors of Shop Solutions published in each issue of Engine Builder Magazine are awarded a prepaid $100 Visa gift card. Shop Solutions may also be submitted to [email protected]. A Better Way to Clean Oil Galleries I’ve always used the standard long handled nylon bristle brushes dipped in solvent to scrub the oil galleries in blocks,

2013 Machine Shop Market Profile Part 1

Since that time, a lot of things have changed at this magazine and in this industry. What hasn’t changed is the fact that we have consistently surveyed the same machine shop/custom engine rebuilder (CER) population to get a snapshot of this industry from the experts – you, the engine rebuilder. Numbers can give a cold,

Assembly Oils, Greases and Lubes

In the October 2012 issue of Engine Builder, I wrote about engine assembly lubes and why you should consider using them. When I was asked to write another article to help engine builders better understand and select engine assembly lubes for their operation, at first I didn’t understand the assignment. I thought I had

Performance Gaskets & Surface Finishes

The most critical engine gaskets are the head gaskets since they have to withstand the heat and pressure of combustion. And unless the engine is a drag motor with a solid billet or filled block, the head gaskets also have to keep coolant out of the cylinders. Many performance engines are capable of making