Gaskets and Engine Sealing

What a difference a century makes. Engine sealing technology has come a long way from the days when motors were expected to leak and drip past the gasket and onto the ground or vent out into the atmosphere. In the early 20th century, when most people were switching from horses to cars, other, more natural

Join PERA and UEM for a Webinar on Piston Coatings

Ken Carter of United Engine and Machine will talk about piston coatings and how they are revolutionizing piston fit and wear.

UEM Dualoy Diesel Pistons

United Engine & Machine has launched its new Dualoy Diesel Pistons. Dualoy Diesel Pistons are made from two alloys, an aluminum casting with an iron top ring carrier bonded in. UEM’s design gives the top ring a much harder surface to operate on.

Pistons & Rings Update

While piston materials and designs have evolved over the years to compensate for higher pressures and heat expansion, selecting a piston that is optimized for combustion chamber conditions can be challenging because there are so many variables to consider.

Emuge Turbine End Mills

Emuge Corp., a manufacturer of high performance taps, drills, end mills and other rotary tools, has introduced an advanced line of end mills featuring unique geometry designed specifically for the high performance machining of turbine and bladed components.

416 cid Turbocharged LS3 Stroker

If there is one thing Carmen Trischitta of CT Performance Machine hates, it’s being cookie cutter when it comes to his engine building. That’s why he takes his time building engines and incorporates custom, one-off parts into builds like this 416 cid turbocharged LS3 Stroker. Find out what makes this engine so impressive.

When to Upgrade Wrist Pins

It has been said that the piston and connecting rod are the most tortured parts in a performance engine. Few engine builders dispute that notion, but what about the less glamorous piece of steel that mates them together through thick and thin? In a sense, the wrist pin is like the unsung soldier who throws

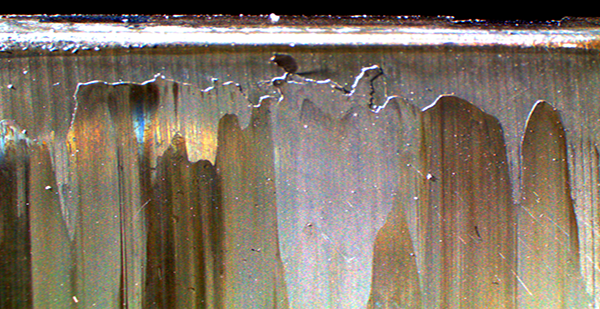

Smooth and Straight

Cylinder honing is easier than ever – if you have the stones to do it right Proper cylinder wall finish is critical for true piston ring sealing and lubrication. Bore geometry is important as well – round, cylindrical and straight are the buzzwords for optimal sealing and minimal blowby. Thanks to better machines designed to

Analyzing Fatigue and Distress

Engine bearing inspection is a great way to get a visual indication of what is going on inside the engine under operating conditions. Upon teardown, the bearings will often have “tell-tale” signs of problems that have occurred and need to be addressed. However, the distress noticed in the bearing is often misunderstood and referred to

Valve Failures Explained

Whether Thermal or Mechanical, Understanding Why Valves Fail Will Improve Your Skill Even engine builders with years of experience have valve failure at some point, but knowing what caused the failure is the difference between a builder who will learn from the mistake and figure out the solution versus one who will continue to make

Performance Oiling Systems

Regardless of what type of engine you are building, the oiling system must be capable of creating and maintaining adequate oil pressure and flow no matter what. Accelerating, cornering, hard braking or extreme RPMs should not cause even a momentary drop in oil pressure. It only takes a few seconds of oil starvation to spin

Understanding How Valve Seats Are Made, How They Work and What Can Happen When They’re Wrong

When it comes to engine cooling, the radiator is kind of a showoff. It sits right up front, catching the best breeze, dominating the conversation. And when it erupts in a cloud of coolant and steam, everyone knows about it. However, the engine valves (particularly the exhaust valves) shouldn’t be overlooked for the role they

Engine Parts: Lifters, Pushrods and Valve Springs

The valvetrain is one of the most critical components in any engine build, be it stock or performance. The lifters, pushrods, rockers and springs must all be strong and stiff enough to handle the loads and RPMs the engine will encounter, and they have to be durable enough to go the distance.

Understanding Today’s Valve Seats

When it comes to engine cooling, the radiator is kind of a showoff. It sits right up front, catching the best breeze, dominating the conversation. And when it erupts in a cloud of coolant and steam, everyone knows about it. However, the engine valves (particularly the exhaust valves) shouldn’t be overlooked for the role they

What Makes a Racing Piston?

That clearly is an open-ended question because the answer will single out the uber-sophisticated pistons designed for Formula 1 and World Endurance Challenge (WEC), yet to be completely literal the response must acknowledge hand-modified cast factory pistons used in Hobby Stock racing at the local dirt track.

Sprint and Stock Car Engine Market

Building engines for sprint cars and late-model stock cars is a good niche to be in if your local tracks have a strong racing program that is attracting significant numbers of racers and fans. It takes both to maintain a healthy market and a steady demand for engine work.

Valves and Seats

When it comes to engine components working together, there are few areas that share the same level of relationship as the valves and valve seats. The factors that affect this duo’s ability to reside in harmony inside an internal combustion engine encompass everything from material compatibility to thermal conductivity.

An In-Depth Look at Crankshafts

In every aspect of an engine, strength is a very critical factor in the life span and performance level that it can achieve. One place in particular where strength is the most important consideration is the crankshaft.

Getting Aboard with Inboard Marine Engines

Marine engine building is a niche market that is much smaller than the automotive market, but it can also be a very lucrative business for those with the know-how and experience.

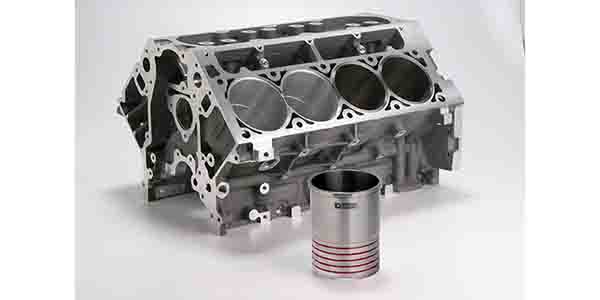

Sleeves and Liners – Metallurgic Magic

Dry sleeves and wet liners have long been used to repair and restore cracked or worn engine cylinders, but they are also used to reinforce aluminum blocks that are being built for serious performance applications.