It has been said that the piston and connecting rod are the most tortured parts in a performance engine. Few engine builders dispute that notion, but what about the less glamorous piece of steel that mates them together through thick and thin? In a sense, the wrist pin is like the unsung soldier who throws himself across the barbed wire barrier while the rest of the troops run across his back. Stroke for stroke, the wrist pin takes one for the team every bit as much as the rod or the piston. If you’re using high-level forced induction, nitrous oxide injection, high rpm or heavy sustained loading on your performance engine, upgraded wrist pins represent the insurance deal of the century.

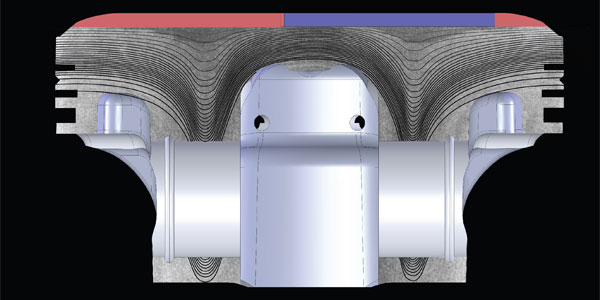

The wrist pin is charged with the daunting task of snatching the piston back from the brink of disaster hundreds of times per second in the face of massive cylinder pressure and alternating loading that can approach 400 g’s. Under these conditions, the pin can bend and distort to an egg shape even if it is well lubricated. The worst case occurs when the piston reverses direction at the top of the exhaust stroke. There is little or no cylinder pressure to cushion the reversal, so the pin bears the full weight of the high-speed piston as it is yanked back down the cylinder. On the intake stroke the piston reverses against rising cylinder pressure that typically peaks around twelve degrees after top dead center (TDC). Here, the inertia loading is also substantial, but it is cushioned by the force of the combustion event.

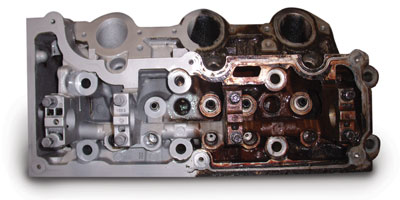

It would be difficult to overstate the importance of the wrist pin in any high-rpm or high-power environment. In some normally aspirated applications seeking maximum compression ratio, many builders push the piston to head clearance right up to the point of leaving very slight witness marks on the piston crowns. Hanging on to the piston at very high piston speeds and tight clearances becomes crucial to engine survival. In other cases, high cylinder pressures via nitrous or forced induction attempts to bend and deform the wrist pin. When the pin bends, it tries to force the lubricant out of the way and friction increases. More power is consumed, and the associated heat tries to destroy the pins, pistons, and connecting rods.

What’s the Best Wall Thickness?

Armed with this knowledge we must ask what factors influence pin choice and what power levels or applications call for increased wall thickness, better materials and/or special coatings? More power always equals more cylinder pressure, so we are obliged to consider parts that complement the engine’s power level. As a rule, most off-the-shelf performance pistons are supplied with appropriately sized pins for the intended application. Of course, racers often abuse that with the addition of power adders that can easily increasing pin loading beyond what standard pins can tolerate.

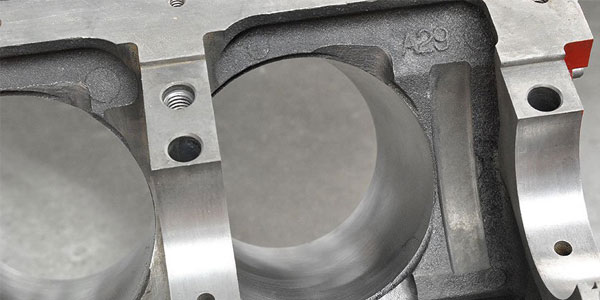

As with everything in racing and many high-performance street engines, pin choice is application specific. Your piston supplier won’t provide something that is not up to the job, but you must be honest with yourself about your intentions. In a racing environment, tool steel wrist pins with a .090-.125-inch wall thickness are often adequate for most normally aspirated applications, but big block engines exceeding 800-1000 horsepower, need pins with a minimum .150-inch wall thickness because they are slinging around heavier pistons. And if you are running high boost or nitrous oxide, the pins must be compatibly thicker and of top grade material. Wrist pin deflection, insufficient pin clearance or poor lubrication all combine to magnify the detrimental effects of an inadequate pin selection.

Here’s a handy ballpark chart you can use for preliminary wrist pin selection before you talk to the techs about your exact requirements.

Normally aspirated

Stock pins 450-500HP

.090-.125 500-700HP

* If you are street supercharging or using a mild NOS shot its good practice to step up a bit more from the recommended normally aspirated pin sizes

Supercharged or NOS

.130-.150 700-1000HP (H13 and DLC recommended)

.160-.250 1000-1500HP (H13 and DLC recommended)

.260-.330 1500HP-plus (M2 or TP1 and DLC recommended)

According to Steve Rhodey at Trend Performance, “The wall thickness is subject to change upon more info obtained at the time of tech. A lot of wall thicknesses will overlap and that’s ok. It’s all about getting the right part. A lot of people have it in their heads that pins only dictate rotational mass, but that’s not always the case considering the loading a wrist pin can see. There won’t be ANY mass to worry about if the pin is too light.”

Among other things to discuss with your tech rep, pin clearance and lubrication quality rank high. Any application powerful enough to flex the pin will benefit from loosening up the pin clearances. Most pins run with a clearance of 0.0008-0.0010-inch. For severe usage and big cylinder pressure, you can avoid trouble by opening the pin clearance to 0.0020-0.0022-inch. Tight clearances are often a disaster waiting to happen. Looser is almost always safer, particularly if there are also lubrication issues.

Typical wet sump systems offer plenty of oil splash to help lubricate the pins. In a racing application, you often have dry sump lubrication, a crank scraper, a pan kickout and a vacuum pump to dramatically reduce oil in the pan and available splash lubrication. Windage and the oil fog can be over-controlled in some cases. Some builders even report greater signs of pin distress on the side of the engine with the crank scraper and pan kickout because they are so effective at stripping away the oil on that side of the engine. Extra clearance always helps in this environment.

In almost every high-pressure environment, tool steel pins, DLC coatings, looser clearances and sufficient lubrication are the insurance you need. Trend Performance addresses these needs with a full range of pin selections to cover every possible environment.

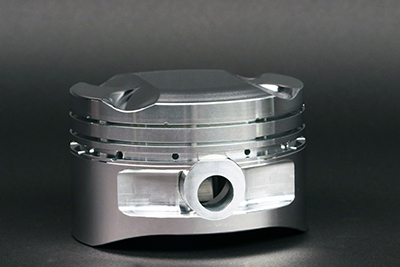

Beginning with Trend’s G-Series, pins are produced from chrome molybdenum 4130 thick-wall solid stock, a popular choice with, piston manufacturers, and shelf-stock piston sellers due to better material and precision machining. 4130 alloys are superior to the common 1018 mild steel alternative. This steel pin is ideally suited for use in naturally aspirated race engines. Pins are heat treated (60 Rockwell O.D./45 core), tumbled, and ground to 0.125 and 0.155 wall selections.

Trend uses H13 tool steel for most of its premium piston pins. H13 is considered the best all-round material for most applications, especially in power-adder engines; it is also a popular choice in Pro Stock drag racing engines. H13 pins have a Rockwell hardness value around Rc54 and easily accept a DLC (Diamond-Like Carbon) coating. These pins are offered for all popular applications in 0.005-.0.010inch wall thickness increments from 0.135-inch to 0.225-inch and 0.225, 0.250, 0.275 and 0.300-inch walls for severe applications. H-13 pins are also ID honed for stress relieving and hard turned ends and chamfers can be added if required.

TP1

A new Trend pin alloy, TP1 is exceptionally hard and very tough. It is coated and less expensive than its rival, C300 maraging steel and it is specified exclusively for Top Fuel, Funny Car, and Pro Stock engines. These new pins are currently available in custom sizes or stocking sizes of 0.270, 0.310 and 0.330-inch. This material is becoming very popular in the high hp sport compact world, pro mod, Radial, sportsmen, arenas. even a lot of limited late model, super late model, outlaw and sprint cars are running it for its ability to be put through hell and stay round.

Top Fuel and Funny Car teams typically run their pins until they bend, which is almost immediately. They don’t coat their pins because it adds expense to disposable components.

Trend believes its new coated TP-1 pin possesses far superior longevity and the ability to resist galling and extreme bending moments. It is heat treated to a through-hardness of Rc60 (hardened from it outer case to its inner core), This pin combines the toughness of the maraging steels and the hardness, compressive strength, and surface qualities of M2, the superior high-speed tool steel.

In terms of tensile strength and yield strength, H13 pins and the newer M2 and TP1 pins are well beyond more common 4130 and 4340 alloys, but they are applications specific. It’s vital that you talk with Trend’s experienced techs to help you “pinpoint” the pin you need for your engine. There is really no environment too tough for Trend Performance wrist pins, but you gain the greatest benefits by upgrading to the proper size and level of prep. A little bit thicker walls with looser clearances and good lubrication can ensure that all the combustion pressure you generate is used to turn the crank and not merely drive the piston down the rod when a pin fails. Don’t overlook this critical step in your build sheet selections.

This article was sponsored by Diamond Pistons. For more information, please visit our website at www.diamondracing.net