Reconditioning cars to prepare them for the used car market is no easy task. The labor hours, harsh chemicals, awkward angles, and use of sharp blades, wire brushes, and rags really add up. What if there was a way to recondition a car – inside and out – in a fraction of the time without the need for the extra chemicals and/or equipment? Enter dry ice blasting!

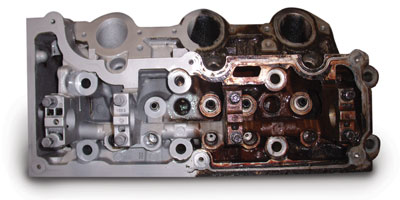

Dry ice blasting is an environmentally sustainable cleaning and surface preparation technique used throughout the entire automotive industry – from component fabrication to the restoration of multimillion-dollar collector cars. This proven technique allows manufacturers, restoration specialists, and used car dealers to remove any contaminants without damaging the surface.

How does it work?

Science. Cold Jet has spent thousands of hours – honestly, probably over tens-of-thousands – perfecting our technology. The unique properties of dry ice, paired with our technologically advanced machines that offer complete control of particle size and blast pressure, offer a water-free, chemical-free clean that significantly reduces labor hours and eliminates repetitive motion and rework.

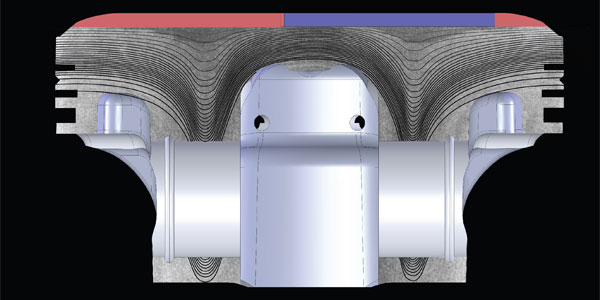

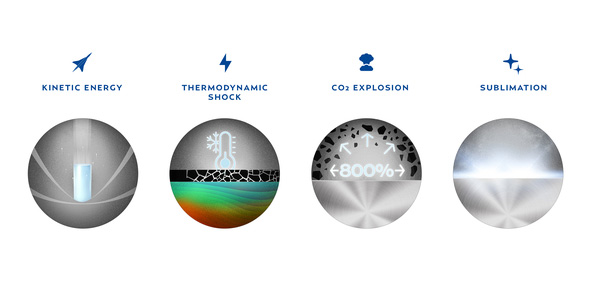

- Kinetic Energy – the soft dry ice pellets are accelerated by compressed air through specially designed nozzles at supersonic speeds. The impact of the dry ice pellets creates a kinetic energy effect.

- Thermodynamic Shock – the temperature of dry ice is -109F/-78.5C. This extreme cold creates a thermal effect that causes the contaminant to embrittle while helping break the bond between the substrate and contaminant.

- CO2 Explosion – the dry ice pellets sublimate – turn from solid to gas – upon impact with the surface and expand volumetrically by 800%, blasting the contaminant off of the substrate.

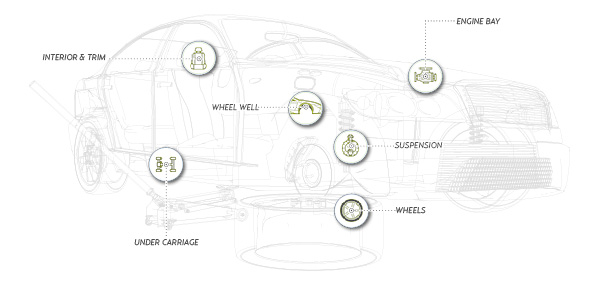

What part of the car is it best for?

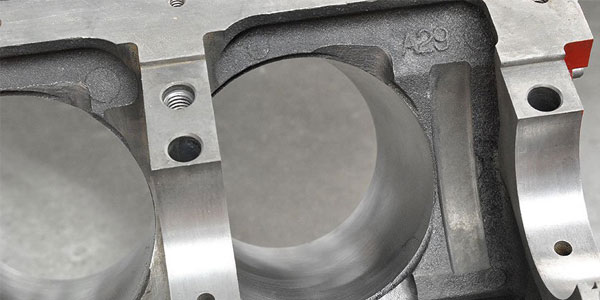

Everywhere! Since dry ice blasting is a dry cleaning method, you don’t have to worry about damaging water sensitive components. Our patented Particle Control™ System allows operators to adjust the dry ice particle size from 0.3mm (grain of salt) to 3.0mm (grain of rice). This allows operators to go from undercarriage cleaning, to engine bay cleaning, to interior cleaning, without changing tools but rather adjusting blasting parameters (and maybe swapping out blasting nozzles).

Since we offer solutions to dozens of different industrial sectors, we have engineered specialty nozzles for any part of the car. This includes special cylindrical nozzles with a 360° blast swath to get in and out of engine cylinders with ease.

Why should you start dry ice blasting?

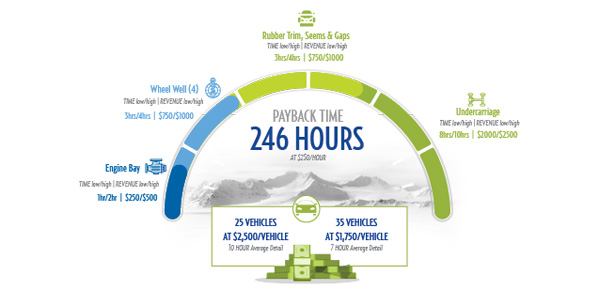

Additional revenue and profits! Let’s be honest, who doesn’t like more money? Dry ice blasting provides auto dealers the opportunity to increase the value of cars after reconditioning – sometimes up to a few thousand dollars depending on the make and model. Auto dealers are also beginning to offer dry ice blasting as a service to their customer base. From our research, the average rate is about $250/hour to dry ice blast a car with many service providers requiring a minimum of 4 hours of blasting. I’m no financial guru, but as you can see these are some very enticing numbers!

ROI calculation example

What do you need to get started?

Ample dry air. Aggression and dry air are the two main components to receive optimal results while dry ice blasting. Without enough air pressure, the dry ice particles won’t be accelerated fast enough to take full advantage of their chemical makeup. Dry air is also crucial as moisture is dry ice’s number one enemy. This is because moisture causes the dry ice to become “sticky” and clump together, causing restricted airflow and ultimately clogging the blast stream.

For best results, we suggest a 15hp air compressor with a built-in air dryer, car lift, and a local dry ice supplier. Fortunately, we manufacturer dry ice production machines and can put you in contact with your nearest dry ice supplier. We also offer small dry ice production systems that require minimal infrastructure, should your operation grow to a point that it makes sense to produce in-house.

Example dry ice blasting setup

How do you get started?

Contact us! If reducing time and cost to recondition and rebuild engines sounds enticing to you, feel free to reach out! We will put you in contact with a local dry ice blasting expert to answer any and all of your questions to help get you started making additional revenue and profits.