We all recognize that internal combustion engines generate heat as a by-product of combustion. Both air-cooled and water-cooled engines deploy strategies to dissipate that heat. This is all done in an effort to keep the engine from running too hot.

But what does that have to do with piston rings? Before we get to that, we need to talk about another source of heat in an engine – friction.

Heat is a byproduct of friction. Think about rubbing your hands together to warm them up on a cold day. The faster you rub your hands together, the hotter they get. Now think about the pistons in your engine moving faster than 200 cycles per second.

That’s why piston rings matter when it comes to engine temperature.

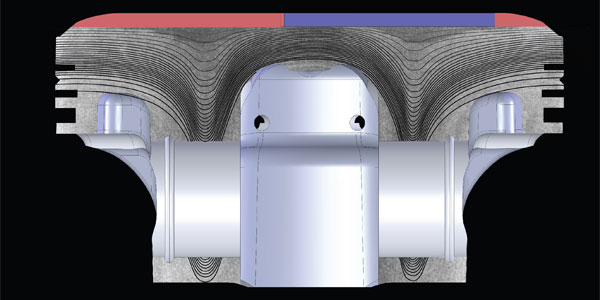

The highest source of friction in an engine comes from the piston rings rubbing against the cylinder wall. Multiple research studies have concluded that the piston ring and cylinder wall account for as much as 40% of all engine friction. No wonder today’s OEM engines have thinner pistons rings than their predecessors.

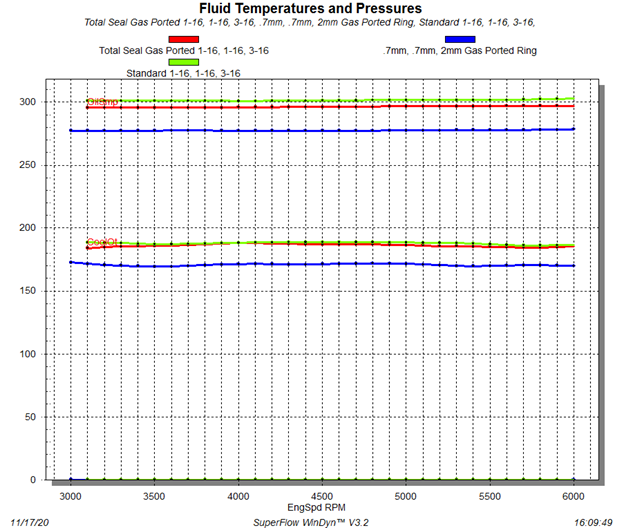

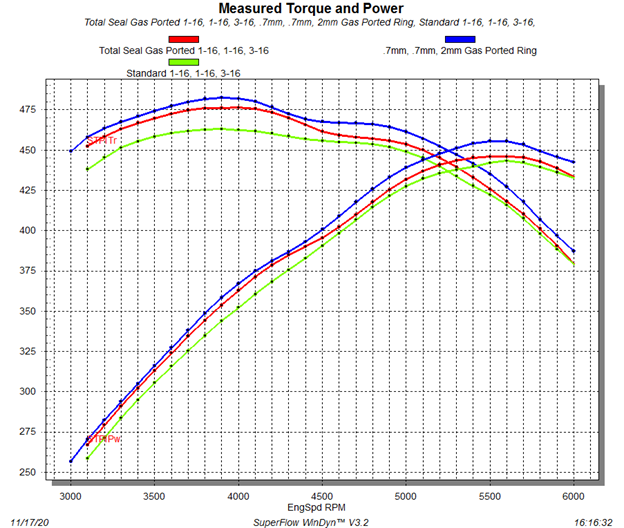

In a recent test at Shaver Specialties Racing Engines the effect of ring size and tension on engine operating temperature was measured.

The base line for this test was a set of Total Seal Diamond Finish .7mm, .7mm, 2.0mm rings. The engine was run at 2,800 RPM with a fixed load setting of 75 ft. lbs. and a fixed coolant flow setting. At the end of 30 minutes, three consecutive dyno sweep tests (3,000 RPM to 6,000 RPM) were performed. At the end of those 3 tests, both water temperature and oil temperature were recorded.

The engine was then fitted with a standard set of 1/16th in, 1/16th in, 3/16th in. rings. Again, the engine was run at 2,800 RPM with a fixed load setting of 75 ft. lbs. and a fixed coolant flow setting. At the end of 30 minutes, three consecutive dyno sweep tests (3,000 RPM to 6,000 RPM) were performed. At the end of those 3 tests, both water temperature and oil temperature were recorded.

Two different tests with the 1/16th, 1/16th, 3/16th rings generated about 15 degrees hotter water temperature and nearly 20 hotter oil temperature compared to the .7mm, .7mm, 2mm ring set.

The results confirm piston ring to cylinder wall friction as a meaningful contributor to engine operating temperature, and identifying friction as the source of the heat was quite easy. The standard 1/16th, 1/16th, 3/16th rings reduced engine power by nearly 20 lbs. feet of torque and over 15 HP compared to the gas ported .7mm, .7mm, 2mm ring set. In fact, the 1/16th, 1/16th, 3/16th ring set generated so much oil temperature that the label on the oil filter began to “shrink” from the heat!

In a “real world” comparison, Joe Gibbs Racing Engines built the new JD-1 desert off road racing engine using Total Seal Diamond Finish .7mm, .7mm, 2.0mm rings. While many other off-road racing engines use traditional 1/16th, 1/16th, 3/16th rings and struggle to keep engines from overheating, the JD-1 engine runs remarkably cool. In fact, it nearly ran too cool during BAJA 1000 when overnight temperatures dropped to nearly 40 degrees F.

All of these dyno and race results point to the same thing, piston rings rubbing against the cylinder walls generate friction, and that friction produces heat and robs power. By going to thinner piston rings, friction can be significantly reduced, and the benefits are two fold – increased horsepower and reduced operating temperatures.

So before you decide to buy a bigger radiator for your hot running engine, you might want to consider trying a set of thinner piston rings first.

This article was sponsored by Total Seal Piston Rings. To learn more, please visit our website at www.totalseal.com.