Not Your Father’s 4.108 Engine

Jay Foley of Foley Engines is taking an out-of-date Perkins 4.108 engine and bringing it into the 21st century. With an array of engine upgrades, this Not Your Father’s 4.108 is a sailor’s dream.

A Job Well Done

If Timm Jurincie stopped accepting engine work today at his Avondale, AZ shop, Tuf-Enuf Auto & Marine Performance, he would still have enough work to last until September. Tuf-Enuf, which focuses on performance marine engines and street strip motors, is a sought-after engine shop in the Avondale and Phoenix area despite not advertising. “We don’t

Industry Still Strong, Say Readers – Engine Builder Readers Tell Us Business Has Changed, But Opportunity Still Remains

For more than 50 years, Babcox Media has covered the rebuilding industry on a monthly basis. At least 633 issues of Automotive Rebuilder and, since 2000, Engine Builder has been dedicated to the business of machining, building, rebuilding and remanufacturing engines. In our very first issue, we made the promise that we would be devoted

Industry Still Strong, Say Readers

Engine Builder readers tell us business has changed, but opportunity still remains.

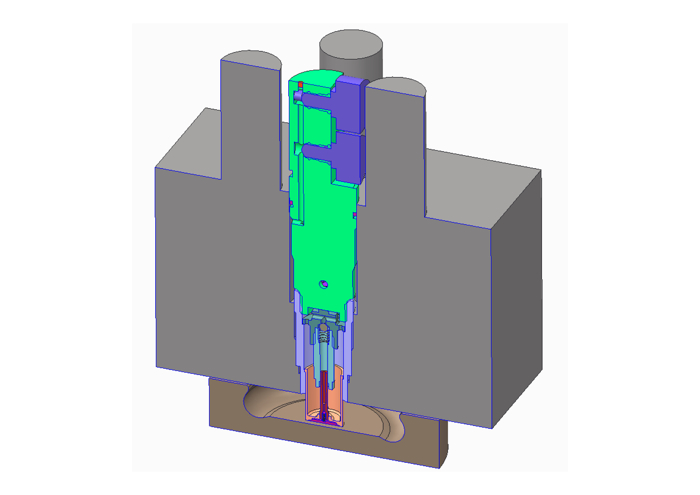

RKLAB AG Diesel Fuel Injection System

RKLAB AG is a technology company in the process of commercializing a new diesel fuel injection system, the RK Injector (RKI). The technology is a self-pressurizing fuel injection system that is a direct replacement for the current common rail diesel fuel injection system.

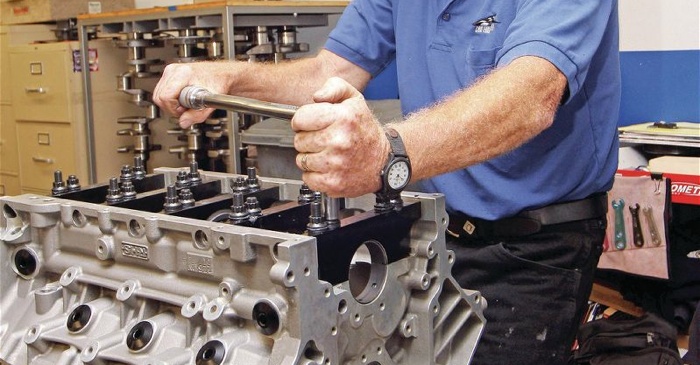

Connecting Rods

They say an engine is only as reliable as its weakest link. The connecting rods that join the pistons with the crank can be a strong link or a weak link depending on the rods that are used.

Shop Solutions July 2015

I made a quick and accurate piston ring aligner for checking end gaps out of a .030 over, 454 Chevy flat top piston. Just chuck the piston in a lathe and turn the ring lands down to a little under 4.000˝. The bottom of the oil ring land is about .950˝ from the top of the piston, and will align the ring in the block.

Machine Shop Market Profile

As we move through our 51st year of covering this industry, the staff of Engine Builder recognizes that old adage – the more things change, the more they stay the same. What’s changed about this industry is, well, pretty much everything. What’s stayed the same is the dedication and hardwork of the professionals who keep engines running and customers happy.

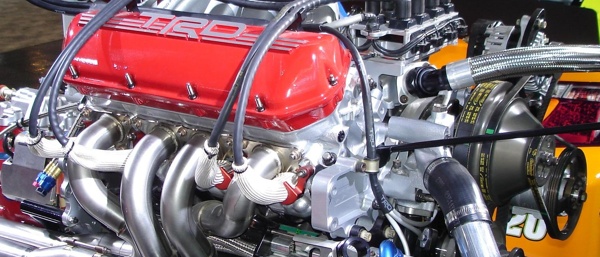

Performance Oiling Systems

The basic purpose of an oiling system is to provide lubrication for the engine. It doesn’t matter if the system is a wet sump with an internal oil pump mounted in the crankcase or front cover, or a dry sump system with an external multi-stage pump. The engine doesn’t know the difference as far as where the oil comes from – as long as the flow keeps coming at all RPMs and under all operating conditions.

Choosing the ‘Right’ Oil

Every engine builder knows the importance of using not only high-quality motor oil in an engine, but also an oil that has the right additive package and viscosity for the application. This is especially important in performance applications where extremes of heat and pressure can push many ordinary motor oils to the brink. Motor oil

Crankshafts and Bearings for Street Performance and Racing

The crankshaft and bearings are the foundation of any engine. The type of bearing and crankshaft materials that are used, their strength properties, fatigue resistance and ability to handle high torque loads ultimately determine how durable the engine is and whether it goes the distance or self-destructs. Most engine builders have strong opinions and

Scratching the Surface: Coatings and Treatments for Engine Components

When it comes to preserving performance parts, it’s the ‘Icing on the Cake’ Various kinds of coatings and surface treatments can be applied to engine parts like icing on the cake to improve durability, enhance scuff resistance and lubrication, control heat, boost thermal efficiency and reduce friction. No single coating or surface treatment can

Shop Solutions: October 2013 Issue

Balloons Belong at Birthday Parties Not in Transmissions I rebuilt a 454 GM engine that went into a motorhome application. It ran well, and no problems immediately appeared. But later on, it was towed in with a main bearing failure in the thrust area. I gave the customer another engine, and a month later it

Future of Engine Building: Industry Forecast

The more things change, the more they stay the same As we entered into the new millennium, the industry had an optimistic, yet cautious outlook as to what the future held for the production engine remanufacturers and custom engine rebuilders. When we asked various industry insiders this month to look into their crystal spheres, past

2013 Machine Shop Market Profile Part 1

Since that time, a lot of things have changed at this magazine and in this industry. What hasn’t changed is the fact that we have consistently surveyed the same machine shop/custom engine rebuilder (CER) population to get a snapshot of this industry from the experts – you, the engine rebuilder. Numbers can give a cold,

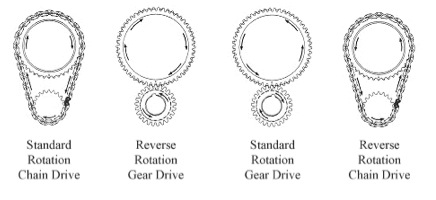

Common Rail Injection History: Less Conspiracy, More Efficiency

It seems as though when customers are at the shop, the question always arises as to what common-rail really means. Then after I explain the technology to them, the reply that I get is, “Why did they have to change everything and start using computers?” If you find yourself in a similar boat and have

Recent Advancements in Racing Oils

The racing oil community has been very busy this past year. This is much more satisfying to an old “oilhead” who has seen years where there were no new racing oil developments. Racers and engine builders traditionally focus more on improvements in hard parts, because that’s what they understand best. However, recent successes in racing

Engine Builder Shop Solutions: September 2011

Editors note: The first two Shop Solutions are responses to Larry Carley’s article “Cleaning Heads and Blocks” in the July 2011 issue of Engine Builder. Cleaning Vintage Mercedes Parts I enjoyed the July 2011 article “Cleaning Heads and Blocks” and wish to include a tech tip about the use of caustic cleaning on vintage Mercedes

Restoration Engine Builds: Finding The Niche That’s Right For You

If you’re trying to determine if you can make money raising engines from the ashes, take the following test to see if you’re likely to, not just survive but, flourish as an engine restorer: • Are you an information sponge capable of soaking up the last 100 or so years of automotive technology? • Do

Crankshafts and Bearings for Street Performance and Racing

Most engine builders have strong opinions and brand preferences when it comes to choosing a crankshaft and bearing combination for a performance engine application. Their preferences (and prejudices) are usually based on years of experience, both good and bad. Many subscribe to the philosophy that “if it isn’t broke, don’t fix it!” Consequently, if they