Regardless of what type of engine you are building, the oiling system must be capable of creating and maintaining adequate oil pressure and flow no matter what. Accelerating, cornering, hard braking or extreme RPMs should not cause even a momentary drop in oil pressure. It only takes a few seconds of oil starvation to spin a bearing or throw a rod through the side of the block!

Every component that is part of an engine’s oiling system must be considered because every component plays an important role in how well the oiling system performs. So let’s look at each of the components to see how they all fit into the bigger picture.

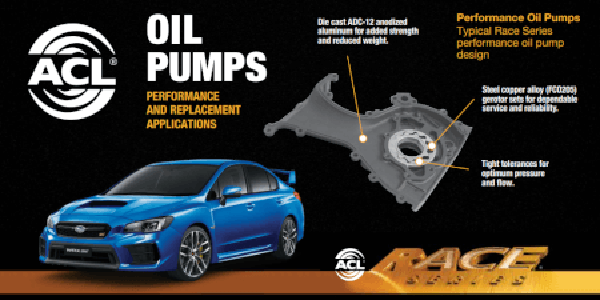

OIL PUMP

Stock oil pumps are usually adequate for stock engines or even modified engines up to a point. Most original equipment oil pumps provide good oil flow and pressure up to about 5,000 to 5,500 RPM before the pump starts to cavitate and output flatlines. That’s not good for a high revving performance engine, so upgrading to a performance pump is a must.

Aftermarket performance pumps with reconfigured inlet and outlet ports flow better at higher engine speeds. Some pumps also come with larger diameter inlet tubs that can flow more oil, including many high volume pumps that can boost flow.

A high volume oil pump with taller gears has a larger internal displacement, so it can move more gallons of oil per minute than a stock pump – typically 15 to 25 percent more oil.

The question is, does every performance engine really need a high volume oil pump?

Some engines do if they have looser bearing clearances because more space between the crankshaft bearings and journals require more flow to maintain the oil film. An engine may also require a high volume oil pump if it has piston oilers for extra wrist pin lubrication and piston cooling, or additional oil squirters for the upper valvetrain, Variable Valve Timing or Cylinder Deactivation. Anything that uses more oil will require more flow from the pump.

A high volume pump can also help boost hot idle oil pressure readings and quiet a noisy valvetrain. But it should not be used to compensate for such things as excessive bearing or lifter bore clearances, or internal oil leaks.

On the other hand, if an engine has tighter bearing clearances and uses a low viscosity oil (say 0W-40, 5W-20, 5W-30, etc.), a stock pump can probably provide adequate flow and pressure.

The downside of installing a high volume oil pump in an engine that doesn’t really need one is that it wastes horsepower to pump the extra oil.

Choosing the right oil pump can make a big difference in how the oiling system performs. Choose a quality brand name pump rather than taking a chance on a low-priced no-name pump. We’ve seen some really bad oil pumps recently that were being sold on the internet as part of engine kits.

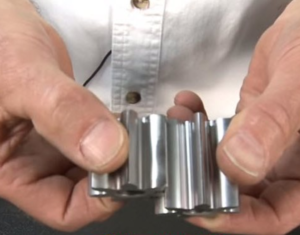

One of these pump failed to prime and develop any oil pressure after it was installed. When the pump was removed and disassembled, one of the two gears inside the pump was missing! That’s a good reason to always disassemble and inspect a new oil pump before it is installed. Check the clearances and make sure the gears mesh and rotate smoothly.

Another SB Chevy pump we saw had no slot in the end of the pump drive gear shaft to mate with the distributor. Another SB Chevy pump casting did not even have a hole drilled in the casting for the mounting bolt that attaches the pump to the block! Talk about no quality control whatsoever!

We’ve also seen numerous dubious quality oil pumps from offshore suppliers that have very loose internal clearances (which greatly reduces pumping efficiency, flow and pressure) as well as ones where the gears bind up when you try to rotate the pump by hand. That kind of junk should never end up in a stock engine, let alone a high performance engine.

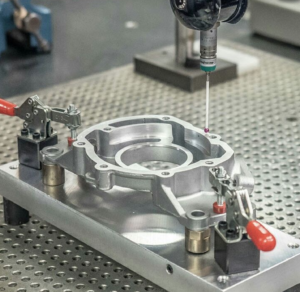

Quality made performance oil pumps often have thicker castings and/or use higher-grade alloys to increase strength and durability. With front mounted pumps (Chevy LS engines, Ford modular and late model Chrysler Hemi), choose a pump that has a strong front cover that won’t bulge outward under pressure and leak oil.

Top-of-the-line billet racing oil pumps provide the ultimate in strength and performance. The CNC machining is highly accurate and the pumps are rock solid reliable under even the most demanding racing conditions.

Another option to consider would be a belt-driven external oil pump. This type of setup allows the use of a shallower oil pan so the engine can be mounted lower in the chassis. It also allows the use of a full-length windage tray inside the crankcase.

Crankcase mounted oil pumps that bolt to the bottom of the engine block typically have no gasket between the pump and block. If both mating surfaces are not perfectly flat and smooth, oil can squirt out of the seam and cause a loss of pressure and flow. Installing a copper gasket between the block and pump can eliminate this potential leak point.

OIL PICKUP TUBES

Increasing the diameter of the pickup tube that feeds the oil pump can reduce cavitation at higher engine speeds and the risk of oil starvation. The screen on the end of the pickup should be a coarser mesh that is less restrictive to flow. The screen is only there to prevent big chunks of debris from being sucked into the pump, so the more open the screen the more oil it will flow and the faster the pump will prime following a cold start.

Some pickup tubes have a welded metal box on the end with drilled holes. The cross sectional area of the holes is important because if the holes are too small or too few in number, it can restrict oil flow.

The pickup tube also needs to be located correctly in the oil pan: far enough above the bottom of the pan so it does not restrict oil flow, but not so high that it increases the risk of sucking air.

WINDAGE TRAY

A spinning crankshaft can whip the oil in the crankcase into a frothy foam at higher engine speeds unless there is a barrier (windage tray) between the oil and crank to keep them apart. Aerated oil can cause erratic oil pressure readings, and the drag created by the crank whipping the oil saps power from the engine. A good windage tray can usually add 20 or more horsepower, and if it has a well-designed crank scraper it can speed the return of oil to the pan.

A related item to consider is a lifter valley oil baffle. The baffle fits under the intake manifold to prevent hot oil from splashing up against the intake manifold and heating the incoming air/fuel mixture. The baffle can also prevent the lifters from popping out of their bores if a pushrod or rocker arm fails.

OIL PAN

An oil pan that provides extra oil capacity is always a good idea for any performance engine. More oil in the pan reduces the risk of oil starvation and loss of pressure, but the pan has to be designed to keep the oil where it belongs so the pickup is always submerged in oil. Baffles and one-way trap doors can control oil slosh when accelerating, braking and cornering, and side kickouts in the pan can hold oil until it is needed when cornering hard.

Using a higher capacity oil pan is also recommended with a high volume pump to reduce the risk of the pump sucking the pan dry.

OIL FILTER

Performance oil filters are purpose built for racing, not everyday driving. Typically, they have coarser filter media that may range from 20 to 27 microns for pleated cellulose/synthetic media filters, or up to 60 microns or more for a screen mesh filter. The less restrictive filter media allows more flow and reduces the pressure drop across the filter. Some spin-on canister racing filters can flow over 25 gallons per minute! Others are in the 12 to 18 gallons per minute range. Be sure to choose a filter that has enough flow capacity to match the application.

A related item is a pre-filter oil screen that fits between the filter and its mounting plate. A pre-filter has a relatively coarse screen (up to 240 microns) so it will not inhibit flow. Its purpose is to trap debris before it goes into the filter. That makes it easier to discover problems that would otherwise require cutting a canister filter open to inspect the filter media.

If an application uses a remote oil filter, your customer should use high strength, braided stainless steel hoses and high quality plumbing fittings so they don’t blow an oil line during a race.

OIL ACCUMULATOR

One of the best engine saving add-ons a racer can buy is an oil accumulator. Accumulators hold 2 to 3 quarts of oil under pressure. The oil can be used to prime a cold engine prior to starting it, or to provide an emergency dose of oil if oil pressure momentarily drops for any reason during a race.

Pressure is stored in the accumulator when the engine is running. If oil pressure drops, oil flows back out of the accumulator to maintain pressure to the engine. Some accumulators have a manual shut-off valve that must be opened prior to starting the engine, and closed before shutting the engine off (to trap pressure for the next start). Remote control solenoids can also used with an accumulator so it can be controlled from the driver’s seat or automatically.

EXTERNAL OIL COOLER

Any engine that’s asked to run lap after lap is going to dump a lot of heat into the oil. Heat thins oil viscosity, which can cause a drop in pressure especially at idle. So steps should be taken to prevent the oil from getting too hot.

Most oil pans don’t provide much cooling so adding an external oil cooler and thermostat can help prevent oil overheating, oxidation and viscosity breakdown. A thermostat should also be used to block flow when a cold engine is started (to speed oil warm-up), and to regulate oil temperature around 160 to 180 degrees.

OIL HEATER

For engines that race in colder climates or sit for extended periods between races (like drag cars), an oil heater can bring cold oil up to temperature before a race. A 400 watt heater in the oil pan can usually heat up 12 quarts of oil in 30 minutes or less so the oil pump will prime quickly and build pressure.

VACUUM PUMP

Although vacuum pumps are used primarily with dry sump oiling systems, they can also be used with a traditional wet sump system to pull air, fuel and oil vapors from the crankcase. The pump is mounted externally and is belt-driven.

Using a vacuum pump has several advantages. It improves ring sealing and allows the use of lower tension piston rings to reduce power-robbing friction. Pulling air out of the crankcase also reduces windage for less drag on the crankshaft and pistons.

DRY SUMP OILING SYSTEM

The best way to make sure an engine receives a steady supply of oil under all conditions is to go with a dry sump oiling system. Dry sump systems use a shallow oil pan with an external oil pump and vacuum pumps. The vacuum pumps suck oil from the pan and route it to an external tank so air and oil can separate. The tank also serves as an oil reservoir, increasing the overall oil capacity of the system and providing a steady supply of oil back to the pump.

To get most of the air and oil out of the crankcase, the suction pumps need to pull at least 8 to 10 inches of vacuum. If more vacuum is needed for higher RPM engines, additional suction pumps can be added to the stack (four, five or six stage pumps).

Dry sump oil systems are expensive ($3,000 to $7,000 or more depending on the setup), and they require a lot of external plumbing, which increases the risk of a leak or blowing an oil line. Also, rules may prohibit their use. Even so, a dry sump oiling system is the ultimate setup for those who can afford it.