They may or may not have had some type of formalized education – yet, they may be well versed and very savvy but have not had the infield experience as of yet. They are not necessarily young, just new to the world of engines.

For them (and even for the veterans), let me give you some facts that you may not be aware of, some of which were in July 2009 EngIntel:

• Antifreeze/engine coolant is the most neglected fluid in the vehicle.

• Cooling system neglect is cited as the principal reason for premature engine and transmission failure.

• Cooling system failure is the most common cause of mechanical breakdown on the road.

• A national survey found that 7 out of 10 vehicles contain rust and scale and two-thirds of more than 8,000 cooling system repair jobs were performed on an emergency basis.

• Just 1/16th of an inch of mineral deposits on 1 inch of cast iron reduces heat dissipation by 40% and is the equivalent to 3-1/2 inches of cast iron.

• Over 60% of water pump failure can be attributed to seal failure.

• Over 50% of engine failures can be attributed to cooling system failure.

Well, that gives you an idea of how critical the cooling system is to a long and happy engine life and how detrimental it can be if it is not in good operating condition. Worse yet, what if the cooling system was the cause of the previous vehicle engine failure and now a fresh reman engine has been installed. What do you think is going to happen at that point?

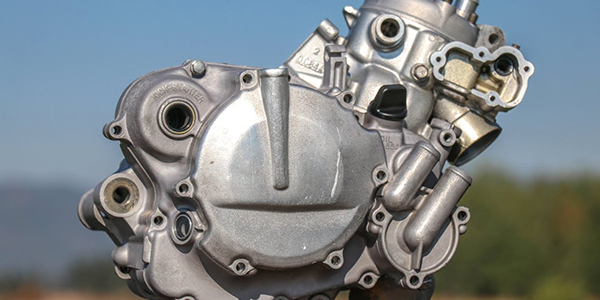

The cooling system is just, that a system (Figure 1). It is a pressurized, sealed circulation unit that consists of six major components:

Anti-freeze/Coolant: The fluid in your cooling system is used as a way to dissipate the tremendous amount of heat an internal combustion engine creates. Most new vehicles have an optimum operating temperature of around 200 degrees F or about 93 degrees C (water boils at 212 degrees F or 100 degrees C and freezes at 0 degrees C or 32 degrees F). Pressure is the second way that the boiling point is raised; most vehicles have between 13-15 psi (pounds per square inch) in the cooling system. This can raise the boiling point of the fluid mixture approximately 45 degrees F or just over 7 degrees C.

The fluid in your cooling system should dissipate the tremendous amount of heat that is generated in the engine. That is where anti-freeze comes in: it is used as a stabilizer to help keep the mixture in the cooling system from boiling or freezing, depending upon when the vehicle is in use. Anti-freeze in a 50 percent mixture with water can change the freezing point from 32 degrees F or 0 C to –35 degrees F or – 37 degrees C. It also moves the boiling point from 212 degrees F or 100 degrees C to 223 degrees C or 106 degrees C.

Water pump: The water pump is a mechanical (or, in some applications, electric) pump that circulates the engine coolant/anti-freeze through the radiator and back to the engine. Mechanical pumps are usually driven by an accessory drive belt or by the timing belt/chain. Look to see more electric pumps in future vehicles since the mechanical pump does rob some horsepower.

Thermostat: The thermostat is a temperature sensitive orifice in the cooling system that opens and closes according to engine temperature to regulate the flow of coolant/anti-freeze through the radiator and back to the engine. This allows for the engine to be run at specific temperatures to optimize the performance and emission levels of the vehicle. Look for a professional builder’s tip (PBT) on thermostats later in this article.

Radiator: Typically mounted at the front of the vehicle, the radiator is basically a box with tubing for the coolant to pass through. The tubing has many “fins” swedged on the OD of the tubing for thermal conductivity. The coolant is driven through the tubing so that air may pass across the fins and cool the anti-freeze/coolant. The fins then act as thermal conductors to dissipate the heat.

If a radiator is thermally efficient there will be at least a 20 degrees F or just over 3 degrees Celsius difference between upper and lower radiator hose. So a radiator that has been flushed and flow checked does not automatically guarantee thermal effectiveness. The fins that are swedged onto the flow tubes can lose their tension and no longer be the heat sink that they were designed to be. Temperature in vs. temperature out is the true testing measure to determine if your radiator and cooling system are doing the job.

Cooling fan: The cooling fan is located directly behind the radiator, whether the vehicle is a front- or rear-wheel drive. Its job is to pull air through the radiator at lower vehicle speeds to keep it from overheating. Cooling fans can either be mechanical (belt driven on the engine) or electric (mounted on the radiator, temperature controlled).

Drive belts/hoses: All of the antifreeze/coolant in your vehicle is pumped through several hoses. Maintaining them is crucial to preventing serious engine damage from overheating. Visually inspect the hoses for leakage, cracks or abrasions and the general integrity of the hose; they should be slightly pliable when squeezed with your fingers. Replace any that are questionable. The drive belt/belts should be inspected regularly as well.

I know that this information is basic and almost mundane but during this economic climate who, if anyone, is replacing or repairing anything on a vehicle unless it’s not working? The old adage “if it ain’t broke don’t fix it” seems to be very prevalent today.

All this brings me to what I want to talk about, as far as premature failures of remanufactured or new engines being installed into vehicles today. Back in the latter part of the ’80s through present day, the design of vehicles took a turn into aerodynamic designs that would enhance fuel economy. The front of vehicles became lower and rounder. Bumpers disappeared and now became part of the frame structure with aerodynamic plastic covers, cab forward designs became common place and radiators are now typically much lower than the top of the engine. The problem with all of this is that filling a cooling system is no longer a simple task and the potential for air pocket hot spots is now a much more common threat.

Bleeding the cooling system refers to removing all air from the system. Air in the cooling system doesn’t transfer heat anywhere close to coolant, causes hot spots and subsequently overheating and can lead to serious engine damage. So bleeding the cooling system becomes a critical part of any engine installation or even if you have replaced a component such as a radiator hose, water pump, or radiator.

If there is a means by which you can fill the engine with coolant, be it through a thermostat housing, an elbow or whatever may be available at a high point of the engine prior to filling the radiator or reservoir it is a good start. Many of today’s radiators may not even have a cap on them and the only access is through the reservoir tank.

There is also equipment available that will actually draw coolant through the system via vacuum, which is an excellent method.

Start the engine and turn the heat to max for the whole process of bleeding the cooling system. Turning the heat to max allows the coolant to circulate throughout the whole system and causes any air pockets to exit from the radiator. Then rev the engine to approximately 2,000 rpm and hold for about 15 seconds. If you don’t have an tachometer on your dashboard, simply push down slightly on the accelerator pedal until you hear that your engine is working slightly harder than it normally does at idle, being careful not to overrev the engine. Do this about three times so that the coolant circulates quickly and so that it pushes out any air pockets that may cause overheating.

Many of today’s vehicles also have bleeder valves that you can utilize to bleed the cooling system. Some thermostats have bleed holes in them also. As added insurance, a Professional Builder’s Tip (PBT) that technicians have discovered is to drill an 1/8? hole in the thermostat to allow for continuous air bleeding.

When you feel that you have bled the system completely install the radiator cap and drive the vehicle for about five to ten minutes or until it reaches operating temperature. Keep your eye on the temperature gauge and make sure that it doesn’t pass the midway point. If the gauge is showing any signs of overheating repeat the bleeding process to ensure that you get all the air out of the system.

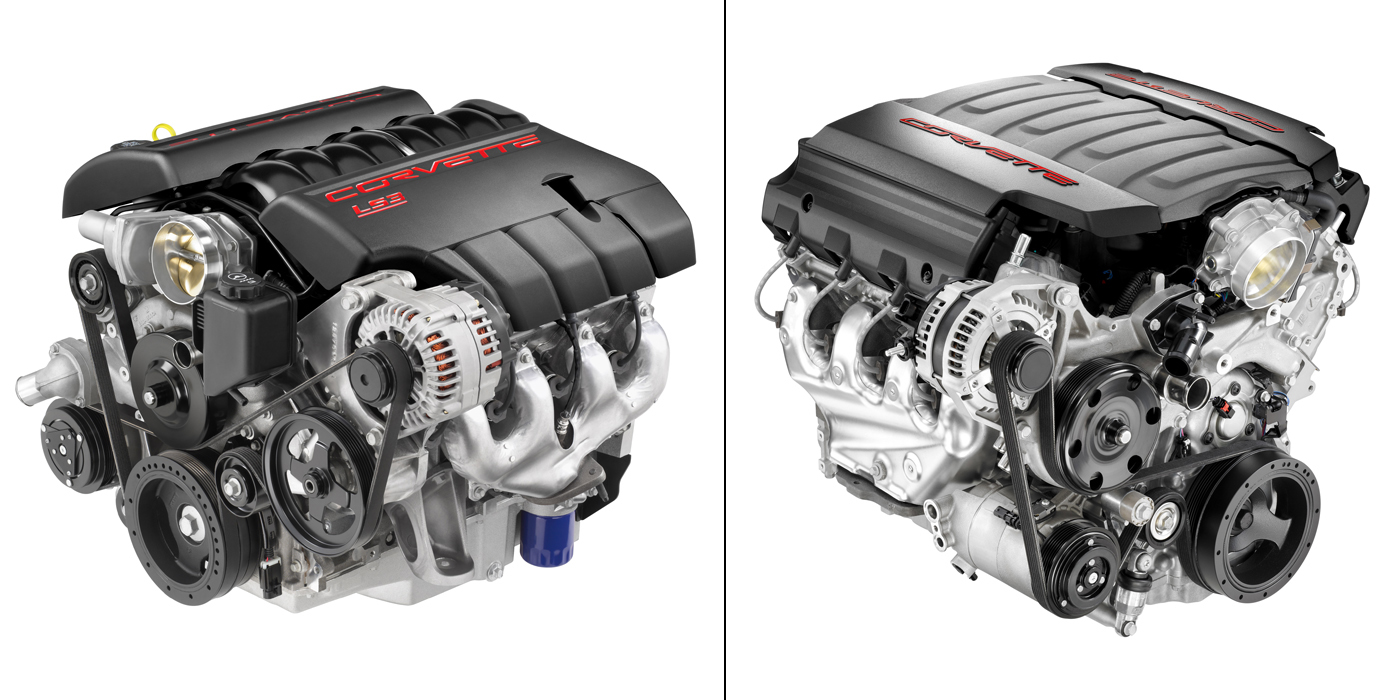

Why have I gone to these lengthy measures to talk about cooling system operation and air pocket hot spots? Because there continues to be a high number of premature engine failures that have isolated piston scuffing on one side of the skirt (see Figure 2). This damage is seen on the inboard side of the engine along the lifter valley, the highest area of the coolant in the engine block. It also scored only one side of the cylinder (see Figure 3).

Even though the piston was correct, the cylinder bore was correct and the clearance was correct, the piston and cylinder still scored due to an isolated hot spot in the cooling system.

So what started out here as a mundane lesson in basic automotive technology can hopefully provide you with valuable premature failure diagnosis. Cooling systems can be a remanufacturer and manufacturers’ greatest enemies, especially if the installing technician does not follow proper bleeding procedures.