Oil leaks have been reported on some 2003-2007 Toyota 4Runners and FJ Cruisers with the 1GR-FE engine.

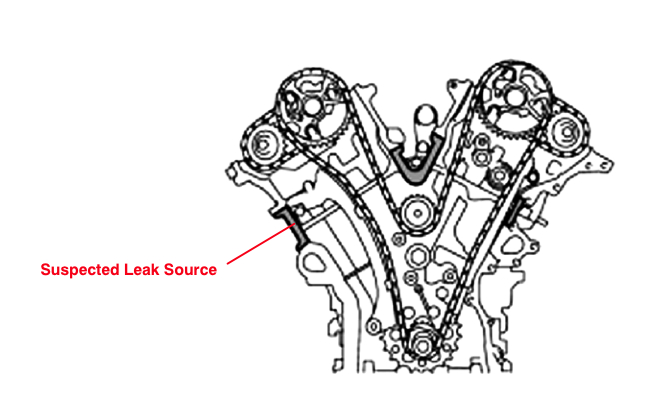

Some 2003 – 2007 model year 4Runner, FJ Cruiser vehicles with 1GR-FE engines may display evidence of a small oil leak located where the Bank 1 cylinder head, engine block, and timing cover meet. Use the following repair procedure to address this condition.

Note: Affects 2003 – 2007 model year 4Runner vehicles equipped with the 1GR-FE engine produced BEFORE the Production Change Effective VINs shown in Chart 1 (affects 2007 FJ Cruiser only).

[inpost_gallery post_id=4994 group=”1″]

1. Inspect the location where the Bank 1 cylinder head, engine block, and timing cover meet for signs of an oil leak (Figure 1).

2. Use an oil dye to confirm the source of the oil leak.

3. Remove and reseal the timing cover if leak is confirmed. Refer to Toyota’s Technical Information System (TIS) or appropriate service manual.

4. Confirm that the repair corrected the condition.

Some or all of this information was provided by the Automotive Parts Remanufacturers Association (APRA). For more information on technical bulletins available through APRA call 703-968-2772 or visit www.AutoBulletins.com.