One curious fact that caught our eye in the latest Machine Shop Market Profile, published in June, was that 41% of readers – engine builders – don’t use a computer to run their shop. This begs the question: if you don’t use a computer for basic bookkeeping, are you using one for machining?

A good, skilled machinist is worth their weight in gold (or used to be before computers took over the world). But today, a machinist may only need to know how to load a machine and push some buttons (not exactly). The need to learn G-code or some other programming language to program a CNC machine is not typically required for automotive machinists unless you’re starting from scratch. Many machine tools built for the automotive and heavy-duty industry are already set up to do basic jobs such as boring, honing and milling. Manufacturers of engine rebuilding CNC equipment have pre-programmed thousands of processes for the most popular engines, so it is (almost) as simple as loading the machine and punching some buttons.

What we hear most often from manufacturers is the biggest obstacle to CNC machine adoption are the shop owners themselves and their reluctance to change. Change doesn’t come easy for those automotive machine shops that have been doing things the same way for 20 years or more. Most shop owners are tradesman first, and businessmen somewhere further down the line. We know that many shops have been around longer than CNC machines and enjoy the old-school, hands-on approach to machining. But a CNC is like an outstanding apprentice that can copy the master artist so he can pass off the work as his own.

A CNC can become your employee without all of the headaches. Your CNC machine never argues (unless you program it that way) or stays out too late drinking beer with his buddies and shows up two hours late for work the next morning. No, if set up correctly and efficiently, the CNC machine can duplicate the most efficient and talented machinist in the shop through automated processes. The operator doesn’t even have to be your best machinist either, and will be able to operate more than one machine at a time. Most manufacturers will tell you that this equipment costs far less than an employee, not that we’re saying you don’t need employees. You absolutely do, and to grow your business, you may need more.

With the computer age well past its infancy, technology is naturally abundant in our everyday lives. You can’t escape computers or touchscreens, even if you don’t own one. Today, most people are used to using a touchscreen because they own a smartphone. The experience on a smartphone has helped instill confidence that a CNC is not going to be too challenging to learn. As a result, more shops are finding out that a CNC is easy to learn and a better all-around machine, so more shops are willing to take the plunge.

With the lack of new engine builders and machine shops, manufacturers are challenged to get existing customers to upgrade their equipment. One manufacturer told us that it’s like trying to convince the shop owner that their manual machine, which has worked for them for the past 30 years, is suddenly worth nothing to their business because it’s too slow. But that is the reality. The older machines can still throw chips, but performing complex operations such as cylinder head porting or milling out large chunks of aluminum is almost impossibly slow, or you have to do it by hand and it’s not repeatable.

Engine builders who have made the switch say the challenges have been well worth the benefits. Many engine builders say they like knowing they can hit the start button, take care of something else, come back and the operation is done.

Not only can shops benefit from automation, but the replication is also crucial. Shops that do cylinder head port work may choose one of the 5-axis machines on the market. While you may have a talented cylinder head porter who can turn out 40-50 heads per year, a 5-axis CNC can increase your output by as much as tenfold. And with even bigger machines available, you can double the production from there.

Shop owners need to look at the capabilities of the potential CNC machine and put it into perspective: A CNC machine is, in many ways, a turn-key business. You still need to go out and get the work, but you will be able to do more and make more than you ever could before using that old manual machine.

The beauty of CNC machines is that they can also run 24/7, if you want. Your CNC machine can be working while you’re at home and it’s making $100 per hour per machine! Another bonus is that when you come in the next morning the job is done, and you are ready for the next one. Some shops have one guy to run multiple machines so you can really leverage your production time.

Typically, what happens is a shop will purchase their first CNC machine and get it loaded up with work to the point they need a second machine or more. With the contraction of machine shops after the recession, there have been fewer shops doing more work to fill the gap. The shops that are set up with the best equipment AND the employees who know how to use them, will get the lion’s share of the business. If you’re thinking now might be the time to make the switch to something more capable, we’ve highlighted a few of the latest CNC machine centers for you in the following:

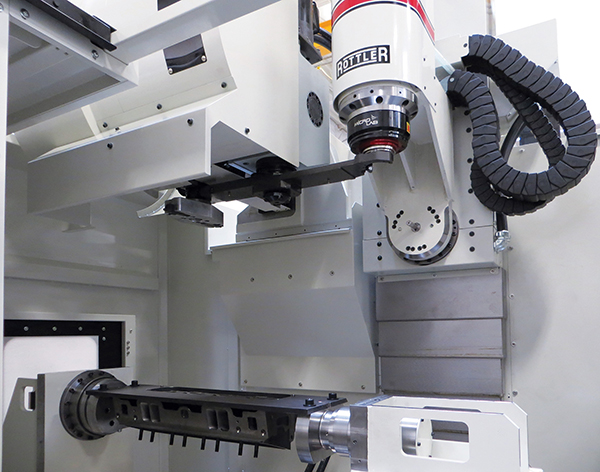

Rottler EM69HP

Rottler’s Next Generation 5-Axis CNC Multi-Purpose Machining Center offers the precision and speed needed to reproduce cylinder heads with exceptional accuracy – with no handwork required. The EM69HP also has the capability of porting intake manifolds with the same techniques used to port cylinder heads while also perform engine block jobs such as boring, surfacing, lifter boring, line boring, lightening and engraving, plus many additional machining requirements.

Features include an advanced high-speed spindle motor with increased power (43HP) and speed up to 20,000 rpm. Rottler’s Computer-Aided Manufacturing Software allows general CNC industrial machining for a wide variety of applications. The EM69HP has swift, rapid movements and cutting speed with infinite look-a-head capabilities offering fast production times. Digitizing is done automatically on the machine using a Reinshaw probe, eliminating the need for an expensive coordinate measuring machine (CMM). All programming and operations are done directly on the Rottler EM69HP 32” Touch Screen Control Panel. The 24-tool automatic tool changer is included as standard equipment for “set it and forget it” operation.

Rottler’s next generation 4C control system extends its capability to include importing of CAD models that can be automatically converted into a toolpath that the machine can then use to execute actual machining operations. The upgradeable software can be networked for enhanced efficiency. The Advanced DM software tools allow manipulation of port design and will reduce digitizing time. This allows an operator to pick up data once and tweak the design (including hand-ported designs) as needed.

Centroid A590

The A590 can port cylinder heads from a wide range of engine configurations: V12, V10, V8 heads, V6, Inline 6, 5 and four cylinders, Import, Motorcycle, Gas and Diesel engines. The Centroid porting system overcomes limitations of other CNC porting machines with its unique and patented technology that creates ports with seamless transitions.

The A590 has the capacity to CNC port long cylinder heads such as inline-6 cylinder gas and diesel heads. The simplified porting process allows you to digitize a head in the morning and be cutting perfect copies in the afternoon.

Weighing in at 23,000 lbs. the new A590 combines quickness and accuracy with a large work table, high material removal rates and heavy part weight capacities with an easy to use operator CNC control interface with the latest CNC software. As the name implies, the A590’sB axis rotates 90 degrees in each direction for a full 180 degrees of movement of the tilting B axis spindle head. The A590 accommodates work-pieces up to 26.5” in diameter and 46” long with a weight of up to 2425 lbs. The X, Y and Z axes provide swift, smooth movement with cutting and rapid feed rate up to 1000 IPM.

The A590 has an optional 40 hp 16,000 rpm B axis spindle with through-the-tool coolant and both the standard 27 hp spindle and the optional spindle are liquid cooled to control thermal growth tightly. Equipped with a heavy-duty B axis drive the new design allows for ultra-accurate positioning at high rotational rates, which yields high metal removal rates while maintaining accuracy, tool life and providing exceptional surface finishes.

RMC V120

The RMC V120 Industrial Engine Machining Center is a large open frame CNC machine designed for all your large engine machining needs. The RMC V120 is a “true” simultaneous 4-axis, pc based, computer controlled industrial standard machining center equipped to handle all facets of precision machining. Whether it be “blueprinting large engine blocks to exact factory specifications or general machining of specialty items, the can’tV120 can do it all. The V120 has a 126” x32” table and travels of 120” x35” x30” (XYZ).

RMC V30

The RMC V30 CNC Head Porting Machine is an entry level open frame CNC machine. The RMC V30 is a “true” simultaneous 5-axis, pc based, computer controlled industrial standard machining center equipped to handle all facets of precision machining, head porting and chamber cutting operations. The RMC V30 has a 54” x16” table and travels of 40” x20” x24” (XYZ).

While some engine builders believe they could grow more if they had a few more pieces in place and more space, it can be a difficult decision to grow or stay put; each has positives and negatives. In the end, it only matters what you want to achieve with your business, and if you’re there now or need more pieces to get there. CNC machining is no longer a future curiosity, it is here now, and many shops are reaping the benefits. Why not you?