When I think of jet boats, I’m reminded of the famous scene from the 1988 movie The Great Outdoors, starring Dan Aykroyd and John Candy. Dan Aykroyd’s character, Roman, rents a jet boat named Suck My Wake to go water skiing with. John Candy’s character, Chet, has reservations from the start, saying, “It’s too much boat. It’s just too much.”

Well, that’s the whole point of a jet boat! Too much isn’t enough and a big V8 engine is the name of the game. As John Candy talks his son through how to water ski, Dan Aykroyd thinks he sees the signal to floor it and takes off around the lake with John Candy accidentally in tow. Candy’s advice to his son just before he flies off the dock is to “let go of the rope if you get in trouble.” Of course, he doesn’t let go, and a hysterical scene ensues.

In drag boat racing, a similar rope is used when starting the race. However, unlike Chet in The Great Outdoors, racers will want to make sure they let go of the rope in order to win!

Jet boat racing started in the ‘60s and grew out of hot rod culture. Stripping down Fords and Chevys to make them go faster quickly translated into boats, and the rest is history.

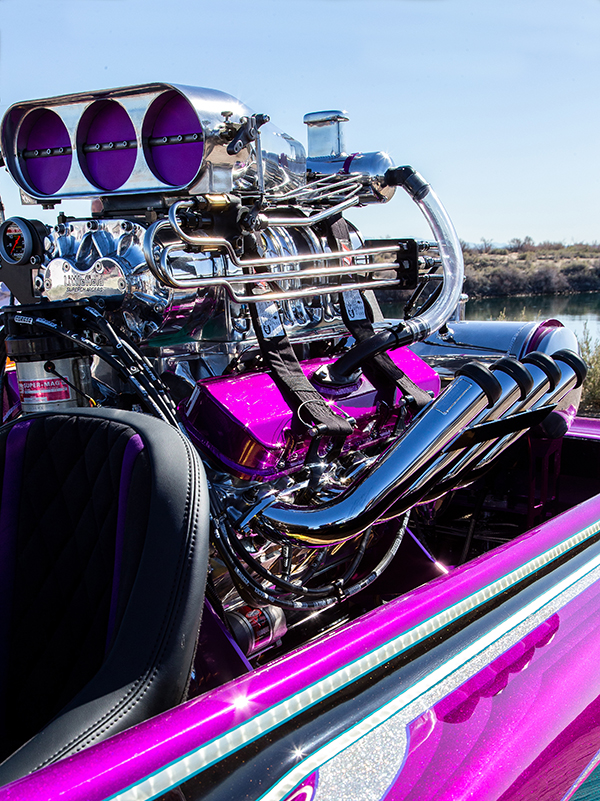

“At one point, there was probably 40 or 50 manufacturers of fiberglass and wooden boat hulls making 100 different models in California,” says Mike Finnegan of Finnegan Speed and Marine. “In the beginning, they ran Chrysler Hemis, big block Fords, big block Oldsmobiles. However, the big block Chevy is the most popular engine in drag boat racing, especially among the sportsman ranks. It’s hard to beat dollar for dollar a big block Chevy on nitrous in a jet boat, so a lot of guys run that. LS stuff is starting to come on pretty hard right now, too.”

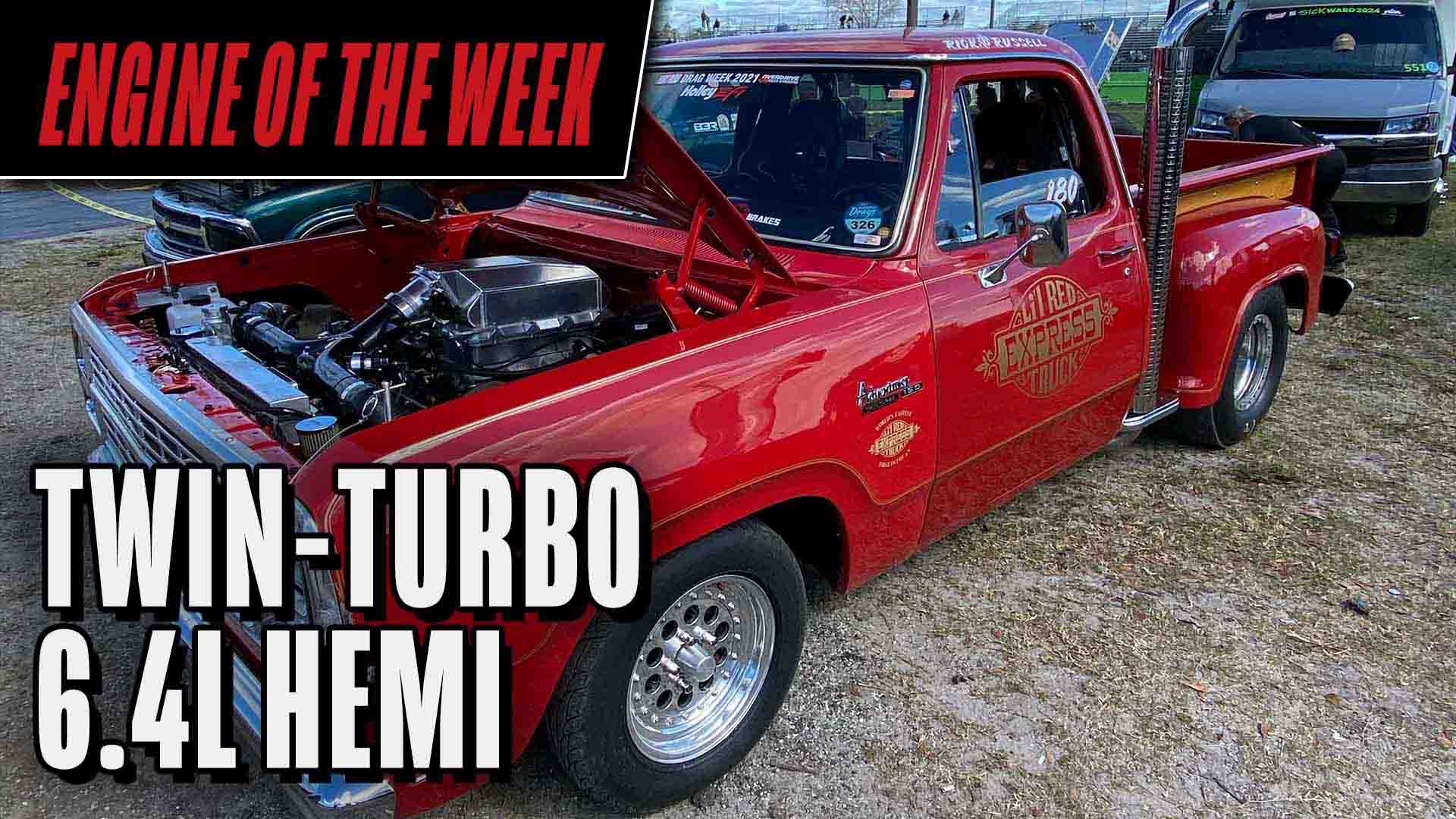

Jet boats and drag boat racing may not be as popular as it once was, but this small niche still has plenty of passionate people who race these boats and build their engines for peak performance. We recently caught up with Mike Finnegan to talk about his history with this class of boat racing as well as his new jet boat project – a 19-ft. Peterson Place Craft with a 711 cid twin-turbo Hemi engine.

“I grew up riding around in the back seat of an old jet boat,” Finnegan says. “It was a 1971 Rogers custom Cyclone. My parents had bought it brand new in 1970 and I grew up riding around in the backseat inches away from a 455 Olds. As a child, I thought they wanted to kill me.”

With a 455 Olds next to him throughout his childhood, Mike learned to love the roar of a V8 engine. This influenced him to get into racing jet boats as he got older and the love for engines, cars and boats has remained to this day.

“I grew up on, and won a championship at Lake Ming in Bakersfield, California,” he says. “That was a man-made lake built in the late-‘60s just for drag boat racing. When I got into automotive publishing, one of my first assignments was to go to Westech Performance in Mira Loma, California and write a story on Steve Brule, the gentleman who runs the place. He raced drag boats at the time, and when I walked into Westech, his drag boat was sitting in there and I thought that is the coolest thing I’ve ever seen. He invited me out to go racing with him and I’ve been broke ever since thanks to him.”

Jet Boat Racing

You can find drag boat races all over the place – as far east as North Carolina to the Colorado river in Arizona, throughout California and everywhere in between. The sport is smaller these days than it used to be, but it’s still happening with associations like the Arizona Drag Boat Association, the National Jet Boat Association and Oklahoma Hot Boat Association, to name a few.

“It’s similar to car racing,” Finnegan says. “It’s broken down by what propulsion you have – whether it’s a v-drive or a jet – and what style hull you have, what displacement engine you have and then whether you have a power adder or not. Most racing associations group power adders together.”

While the objective of drag boat racing is the same as drag racing cars, that’s where the similarities end. Boats don’t have brakes and most of them don’t have transmissions, so the starting line procedure is very different from automotive.

“We race a quarter of a mile, but before the traps there’s about a 75-100 foot run up to the timing traps where they begin,” Finnegan says. “That is to pair the boats up. You basically start the drag boat race sitting there holding onto a rope that’s stretched across the lake or river. There’s two lanes and a pontoon in between both lanes with a guy with a pulley system sitting on the barge. He’s the starter.

“Each racer gives a thumbs up that they are ready and the starter will lift the rope up. You’re idling and holding onto that rope to keep the boat from moving. They give you about 30 seconds to warm your motor and directly above the Christmas tree you have a clock that counts down either from 30 seconds or 10 seconds to zero. Your job as the driver is to time how long it’s going to take you to let go of that rope, mash the gas pedal and get to the timing beams. The goal is to get there at zero when the lights go green.

“I think it’s as hard to do as hitting a 100-mph fast ball from a big-league pitcher. There’s other people holding on to that rope. The rope is moving. Your boat is moving. There’s wind. The race track surface changes every second and you’re trying to time all of that and hit the beams at the exact right moment when the tree goes green.

“If you’re too early, you red light just as in car racing. If you’re too late, you’re probably going to lose the race. If you’re good at it, it’s a really, really good skill to have and you’ll win a lot of races right there at the starting line.”

Drag boat races are typically an 1/8th-mile, 1,000 feet or a 1/4 mile in length, depending on what class you’re in. Due to the water and the effort a boat goes through to produce speed, ETs in drag boat racing are much different than with cars.

“The speed is lower than car mph and because the track is longer, the ETs are a little different,” he says. “For example, my last boat would run the 1/4 mile at about 7.30 at 145 mph. In a car, it’s closer to a mid-8 or low-9-second pass. I actually don’t know anyone who’s ever just gone all the way up to the beam, stopped the boat and then hit the gas and went to see how much slower they actually went. That would be more realistic in terms of comparing the boats to the cars.”

The 75-100-foot starting distance is there to eliminate the time it takes for boats to gain some speed and get on plane before reaching the timing beams.

“When you hit the gas pedal on most of these boats, they kind of go up before they go forward,” he says. “Getting them to break the beams, you have to have all that happen, that motion of the boat leaving the water, landing back in the water, getting on plane and going forward. You need all that to happen before you get some speed.”

However, once you get going, Finnigan admits, “In a boat on the water with no windshield, it feels like you’re going to the moon.”

Building a Jet Boat

As with any form of racing, drag boat racing takes some serious cash. With Mike’s career in publishing, affording to go racing meant learning to build a boat and engine himself.

“I couldn’t afford to pay anyone to build a race motor,” Finnegan says. “I learned everything the hard way. I had some really great mentors who taught me. I blew up a lot of stuff too. Living in Southern California, there aren’t a lot of places to go racing. There’s not a lot of drag strips there. I was able to, through jet boats, build engines that were ridiculously powerful that I could never truly enjoy on the street and just beat the snot out of them and learn about them and break them in jet boats on lakes and rivers that had no speed limits.

“For me, that was the beauty of the jet boat. It didn’t matter what I built, I could stick it in a jet boat and go find out what happens. I’ve been doing that my whole adult life and it’s culminated with this most recent build, which is fairly ridiculous and useless and not legal for any kind of modern jet boat racing, but I always wanted to build a twin turbo kit myself and further my EFI learning. Building this new boat allowed me to improve my fabrication skills and learn a whole bunch of new skills.”

Finnegan had reached the limits of his prior boat and engine, which was a standard bore space, aluminum, big block Chevy that made about 1,600 horsepower with a single stage of nitrous. For his new boat, he wanted to see what turbos could do, so he got to work building out the new combination.

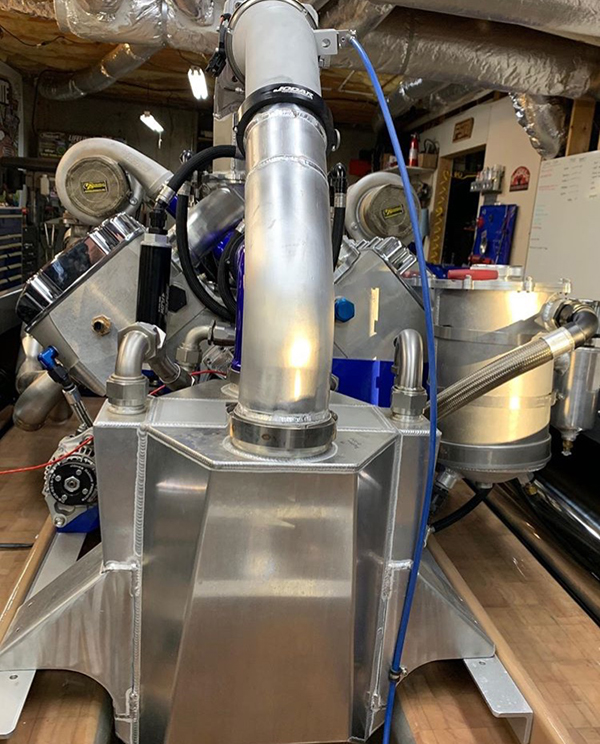

“I knew I didn’t want to stick with a 4.840˝ bore space block because it was starting to move around,” he says. “I thought, all right, I’ll go to a 5.000˝ bore space deal, because that’ll give me more meat between the cylinders and maybe it’ll handle the extra cylinder pressure a little better. I went to Mike Moran (of Moran Motorsports), and Mike Moran helped me bench race the combo and picked the stroke I was going to run. I told him what I was interested in was not a big power number, but I wanted something that would spool really fast and I wanted to go 1/8th-mile racing. I just wanted to spool instantly and build boost quickly.”

With a giant stroke, 5.000˝ bore space engine, the cylinder head options Mike had were slim. He ended up going with a set of Sonny Leonard Hemi heads on a Brodix 5.000˝ bore space block.

“The head dictated I needed a 4.700˝ bore and before I knew it, the engine had grown to 711 cubic inches,” Finnegan says. “The power capability of that is more than I need to do what I want to do, but the parts I had kind of dictated that’s how big the engine was going to be.”

Inside, the engine features forged CP pistons, steel Carrillo connecting rods rather than aluminum for added durability, a Sonny Bryant crankshaft, Manley valves, a COMP Cams camshaft, aluminum T&D rocker arms, a Jesel belt drive and Jesel .937˝ diameter bushed high bar lifters, a Dailey dry sump oiling system with a Dailey low profile billet pan, a Moroso dry sump tank, a belt driven air/fuel pump, and plumbing from Earls.

Sonny Leonard’s shop assembled the long block and dynoed the engine naturally aspirated on pump gas. It made 1,275 horsepower. From there, Finnegan fabricated his own stainless steel turbo system and cold side piping and stuck two Precision turbos on it.

“We’re running two Precision turbo 66mm blow off valves and Precision wastegates,” Finnegan says. “The intake elbow is an aluminum deal that a friend of mine fabricated and welded together. Ignition is all controlled by a Holley Dominator. It runs everything – the EFI, the data logging and the ignition system. Right now, I’m running it on Rocket Racing 118 octane leaded fuel with a giant intercooler from Precision.

“We basically have an unlimited supply of fresh cold lake water because it’s a boat, so the jet drive is feeding the intercooler. The intercooler heats the water up a little bit and then it goes in through the front of the block and then dumps overboard out the back of the cylinder heads. For oil I’m running AMSOIL 50 weight.”

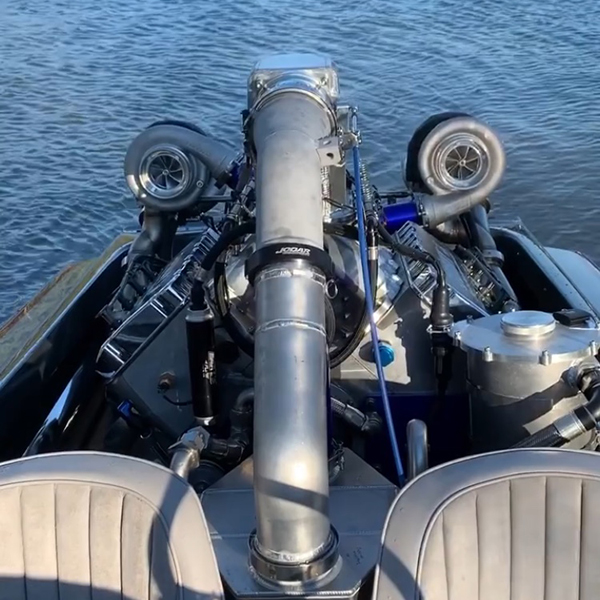

Since getting the 711 cid twin-turbo Hemi engine completed, Coronavirus has squashed any opportunity to get the engine back on the dyno for further tuning, so Mike has been tuning it using the Holley Dominator EFI while out on the lake.

“I go out there and drive it a little bit, log it, stare at the air/fuel numbers and the EGTs and make changes and go drive it again,” he says. “It’ll take a lot longer to refine it that way and make it safe to go wide open throttle, but we’ll get there eventually.

“I’m currently running it with 6-lb. springs in the wastegates. I have a CO2 system onboard the boat to the increase the pressure on the wastegates if I want, but we’re a long way from that. I’d say conservatively at 6-lbs. of boost, it’s probably making 1,600 horsepower right now. We could turn it up and do a lot of things to make a lot more power than that. I’d be comfortable running it right around 2,000 horsepower.”

While Mike was building the Hemi engine, he was also outfitting his new boat hull – a Peterson Place Craft – from Peterson Boat Specialties in Lake Havasu City, AZ. The hull is 19 ft., 6-inches long and weighs 420 lbs.

“It’s really light. The hull is made out of fiberglass,” he says. “The bottom of the boat is really thick, so it’s nice and stiff and maintains its shape, but the top of the boat is really thin to save weight. The entire thing ready to go racing probably weighs about 1,600 lbs.”

The hull came empty, so every scrap of aluminum in the boat used to mount anything was fabricated in Finnegan’s home garage, except for a couple of pieces bought from B1 Racing in Santa Ana, CA. They made the steering system, the billet gas pedal and the dominator jet drive.

“The jet drive is what powers the boat,” he says. “The engine is direct drive to the jet drive. There’s a short aluminum drive shaft – there’s no transmission.”

With the engine’s steel rods, Finnegan expects the 711 cid Hemi engine should be good for at least two seasons before he’ll need to do any serious refresh work.

“I go two seasons, sometimes three, but I would be constantly leaking it down, constantly checking valve lash, constantly looking for lifters going away,” he says. “I would take the lifters out every season and look at them, but the bottom end would stay together for a pretty long time.” EB