Similar to the United States, the United Kingdom (UK) is well-known for its fondness of auto racing. One such example is the worldwide racing organization of Formula 1 (F1), which has a strong UK presence. In the UK motorsport valley area, F1 has approximately 4,300 companies that encompass a supply chain of sub-contractors employing over 40,000 people and generating over $13.7 billion dollars for the UK. It is no surprise then, that only the best, leading technology is used by F1 racers to manufacture its race cars.

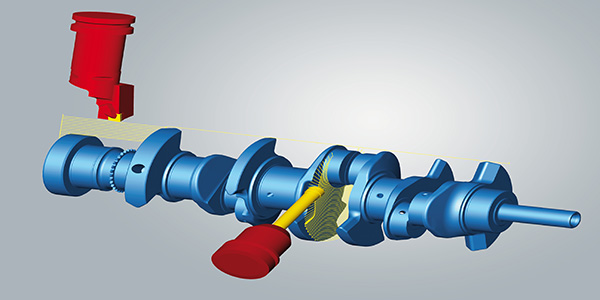

For an optimal process, 5-axis machining is preferred to efficiently produce components with the complexity that is required. Racing parts include intricate components such as pipe inlets and outlets for pumps and compressors, impellers, blisk-rings, turbine blades and gears. Also, intake and exhaust engine tubes that require machining of strongly undercut geometries. Racing parts are manufactured with exotic materials, including titanium. Titanium is an ideal material because it is both high strength and lightweight, however, these same properties can make it challenging to machine.

CAM programming for 5-axis machining should include strategies for steep wall cavity machining, concave and curved surface machining, as well as the ability to produce superb finishes. Also, to keep pace with the fast moving and shifting motorsport industry, CAM software capabilities must evolve at a similar rate.

OPEN MIND’s hyperMILL CAM software is critical for programming and manufacturing precision engineered race car parts for the majority of the F1 starting line. hyperMILL is successful in enabling 5-axis strategies for fast, easy-to-use programming, resulting in reduced cycle times and high-quality surface finishes. Three application examples follow, which discuss how hyperMILL played a key role for F1 component manufacturers in the UK producing challenging 5-axis parts.

Precision Parts

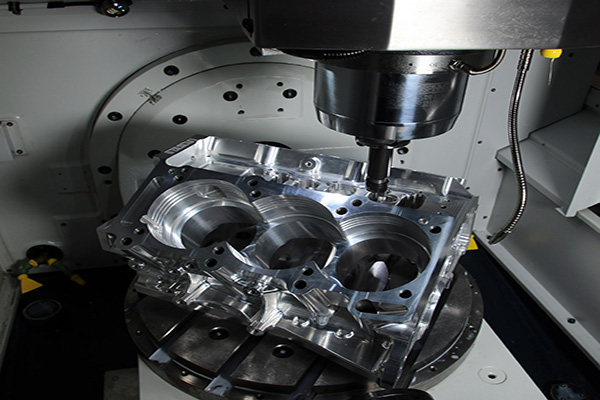

AliTech Precision (Silverstone, UK) is a motorsport subcontractor that had a challenge when they undertook full simultaneous 5-axis machining. AliTech machines complex engine blocks and needed to determine that the CAM software programming was correct before any machining commenced.

“With our previous CAM solution, we found simulation and collision detection was not really at the level of OPEN MIND’s hyperMILL software,” says AliTech Founder Darren Cudd. “Using hyperMILL, programming times are now reduced by at least 50%, and we have complete confidence in its collision avoidance capabilities.

From design to manufacture, previously AliTech was looking at more than 100 design hours and another 100 or more programming hours to produce the engine block.

In another example, AliTech machined a billet turbo manifold that required two 1.6˝ diameter oval-shaped port holes featuring a curved depth of over 7.9˝. hyperMILL modeled the work envelope and detected the collision parameters for the cutting tool, toolholder and machine spindle.

“By precisely simulating the process, we are running at high speed and the tool holder is as close as .010˝ to the port walls during high-speed machining,” Cudd says.

At the same time, the Z-Level Finishing cycle in hyperMILL is being used to tilt cutting tools at angles very close to the wall of the port holes, so that AliTech can run short-length cutting tools in port bores. This results in improved stability and rigidity, surface finishes that permit machining at high speed and feed parameters, and improved surface finishes in port bore. Cudd and AliTech Precision use hyperMILL to efficiently machine around corners on internal pockets in the manufacture of inlet manifolds, inlet port heads and valve seats.

Tube Machining

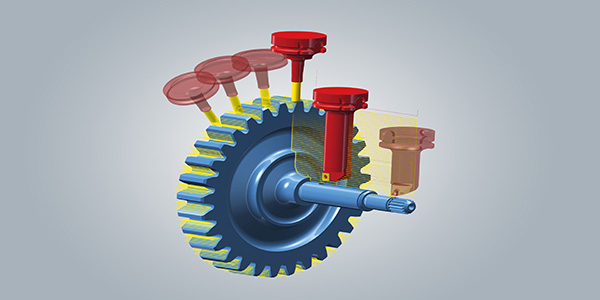

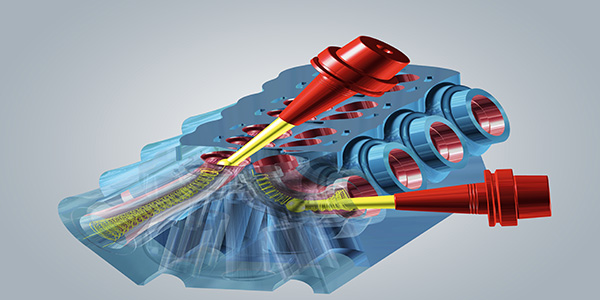

Machining engine ports, cylinders and numerous other complex bore geometries in racing components demand precision finishing. To accomplish this, a core feature in hyperMILL used extensively by many UK F1 teams is the tube machining strategy. The easy-to-use process carves a toolpath down the center of a tube and then works outward to conduct finish-machined operations.

For the machining of engine ports, machining the bore is not the most complex job, but achieving mirror finish surfaces on curved features in deep pockets while avoiding tool collisions is challenging. Also, some F1 teams want undercuts at the bottom of the ports to remove excess material, which is generally a weight reduction strategy. This introduces having to remove the tools from the bore and ports without tool collisions or marking the mirror-finished bores.

Machining for the Finish

Turnaround from billet to finished part must be swift to meet F1 industry demands, and race cars may succeed or fail on the track due to their weight. For that reason, the weight-to-power ratio of an F1 car is a critical factor, and all car components must be engineered as lightweight as possible.

While hyperMILL has a reliable track record in the manufacturing of F1 components, the finishing module in hyperMILL MAXX Machining is now making new inroads. The strategy of 5-axis tangent plane machining is reducing cycle times upward of 90%.

hyperMILL MAXX Machining incorporates a strategy designed for cutting tool geometries that are known as conical barrel or circle segment cutters. It supports geometry and collision checking of conical barrel cutters, tangential barrel cutters, lens tools and barrel tools that are beyond conventional geometries.

With curved geometries beyond standard “ball nosed” tools, barrel tools enable the machining strategy to achieve a vastly greater tool step-down. In comparison with a common ball nose tool that has a step-down capability of .008˝, the barrel tools can operate with a step-down of .118˝ or more. This dramatically larger step-down capability reduces production times up to 90% while improving surface finishes.

Goodman Precision Engineering in Milton Keynes, UK is another F1 subcontractor that has realized significant productivity gains using the hyperMILL MAXX Machining Performance Package.

“hyperMILL MAXX Machining has given us massive cycle time improvements when roughing steel, titanium and other challenging materials,” says Goodman Precision Engineering Owner Mark Goodman. “The roughing and trochoidal milling cycles on hard materials are now over 70% faster and we have improved tool life by over 30%.”

For fast cutting and higher speeds with larger cutting depths, Goodman is using harmonic helix solid carbide end mills, and together with the milling strategies enabled by hyperMILL MAXX Machining, Goodman Precision has reduced its spindle load by up to 50%. The milling tools are performing for a consistently longer time.

“Having this confidence in our tools is invaluable when we are running lights-out or when we are working under tight deadlines to get parts to the track.” EB