SHARPENER

If you have one of these style sharpeners, we have found the rest and stop can be adjusted to sharpen your drill bits on the appropriate angle for a sharp tip every time.

Adam Cofer, Don Ott Racing Engines, York Springs, PA

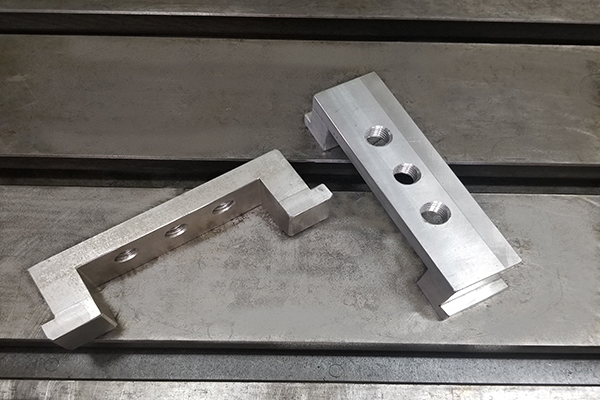

T-SLOT BRIDGE

Occasionally, when clamping an odd-shaped part like a cylinder head or small engine block on our Bridgeport mill, the mill table’s T-slots are not always spaced for convenient clamping. To make the job easier and faster, we machined a pair of steel T-slot “bridges.” We tapped them to accept the same T-slot fasteners used on our Bridgeport mill.

Tom Nichols, Automotive Machine & Supply, Inc, Joshua, TX

GET YOUR BEARINGS

When baking and shot peening cylinder blocks, I leave the main bearing shells and the cam bearings in the block to protect surfaces and maintain concentricity.

Anthony Rotella, Anthony’s Marine & Service, St. Petersburg, FL

BLOCK SQUARED

For those using the common block deck indexing fixture, here’s an easy way to check accuracy of the front plate. When you finish squaring up a block, flip the plate backwards and check the deck across the surface to the plate again. It should read the same if it’s perfectly 90° from bank to bank and 45° from the cam tunnel.

Ron Flood, Cedar Machine, North Branch, MN

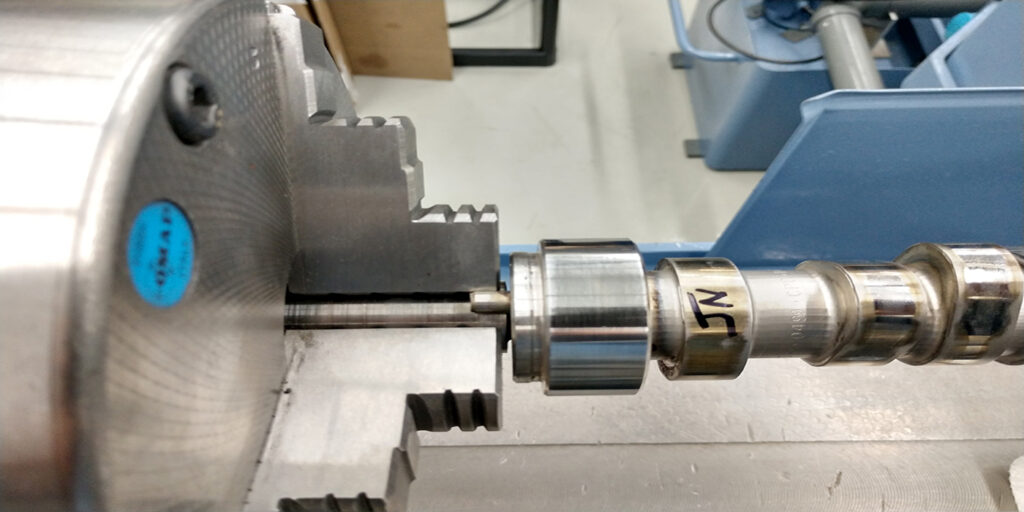

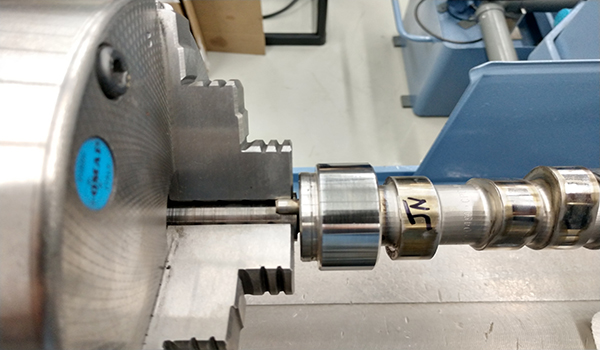

CAM CENTERS

When I need to polish the main journals on a camshaft, I use a straight shank center, or a large center drill will work. Insert the center deep enough in the chuck so the cam pin or a stud will rest against a chuck jaw. All cams have the centers on both ends, so in the rear have a center in the tail stock. Take up the slack and go to polishing. The “old machinists” did this with drive dogs on their crank grinders and lathes.

Randy Torvinen, Torvinen’s Machine, Menahga, MN

TRACKING WORK ORDERS

Because we have a stack of work orders, about an inch thick, we have a system that helps us match a customer with their job, when they call. The work orders are kept in numerical order on a clipboard. The customer is assigned a work order number, he is instructed to save and remember that number to be referenced when calling for info, or when emailing for updates. We also use these numbers to track emails for parts inquiries and as a purchase order number as well.

For example, Joe Blow’s 540 on work order #2158 would have the work order (W.O.) # JB540/2158. When a customer calls for info and gives us the W.O. number, we can find it in the stack very quickly. When invoices come in with this as a PO, we can match it to the W.O. as well.

Rich Jones, Redline Automotive Competition Engines, Davie, FL