STRAIGHTENING WITH STUDS

Smaller crankshafts and camshafts are so “springy” they can resist straightening and can be hard to straighten by peening. I prefer to use a peening technique on all the crankshafts and camshafts that come through the shop. When on the straightener, these parts will typically bend several thousandths with just a slight push of the hand. A couple of 2˝ x 4˝ boards perpendicularly screwed together provides greater support for these smaller parts and makes the straightening process easier. I like to lay the boards between the V-blocks on the straightener so it’s easy to transition.

Trevor Wells, Schmidt Automotive, Indianapolis, IN

CLEARLY CURTAINS

Due to a recent addition of shop equipment, all our machines were moved to make room. To help keep close or neighboring machines from getting each other dirty from flying debris, I used an inexpensive shower liner as a wall between them. Hung with a scrap piece of conduit and zip ties, the installation took only a few minutes. The clear liner still allows shop light to shine through so there are no shadows on the work piece.

Josh Mitchell, Mitchell Machine Works & Custom, Neligh, NE

QUICK & EASY STRAP WRENCH

The diameter of a diesel engine oil filter was larger than my biggest filter wrench, so I made this strap wrench from an old spark plug socket, worn-out poly-V serpentine belt, and a short length of PVC 1/2˝ schedule 40 pipe. I used an angle grinder to quickly slot opposite sides of the socket. I fit the belt through the slots and then tapped a short length of PVC pipe into the socket. You want just enough to keep the belt in place, but not enough to prevent the belt from sliding. Slide the belt in the slot to adjust for size. Trim the belt’s length as desired.

Tom Nichols, Automotive Machine & Supply, Joshua, TX

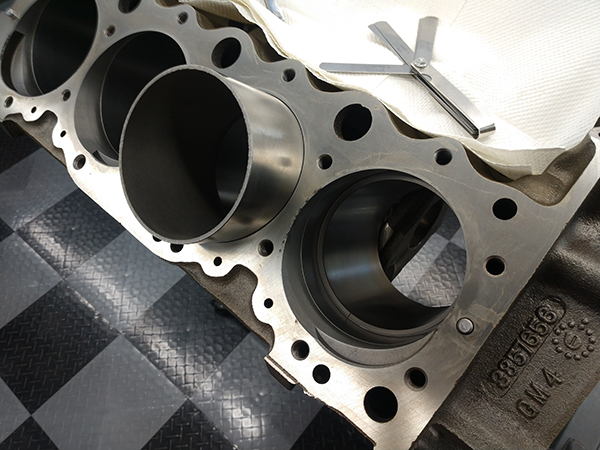

IT’S HIP TO BE SQUARE

It’s tough to end gap rings in a canted deck engine such as a 409 Chevy. Turn a scrap piece of cylinder sleeve to about .003˝ smaller than the bore. Make sure it’s long enough. Use that and it will allow you to push the rings down the bore square. You can also do this with a conventional deck to push the ring past the torque plate distortion if you want to get really nitpicky.

Randy Torvinen, Torvinen’s Machine, Menahga, MN

FALSE SEAT I.D.

When trying to determine if an iron head has a false seat ring in, we have found the fastest method is to mag-check the head. If it has a false seat in it, you will know instantly.

Adney Brown, Performance Crankshaft, Ferndale, MI

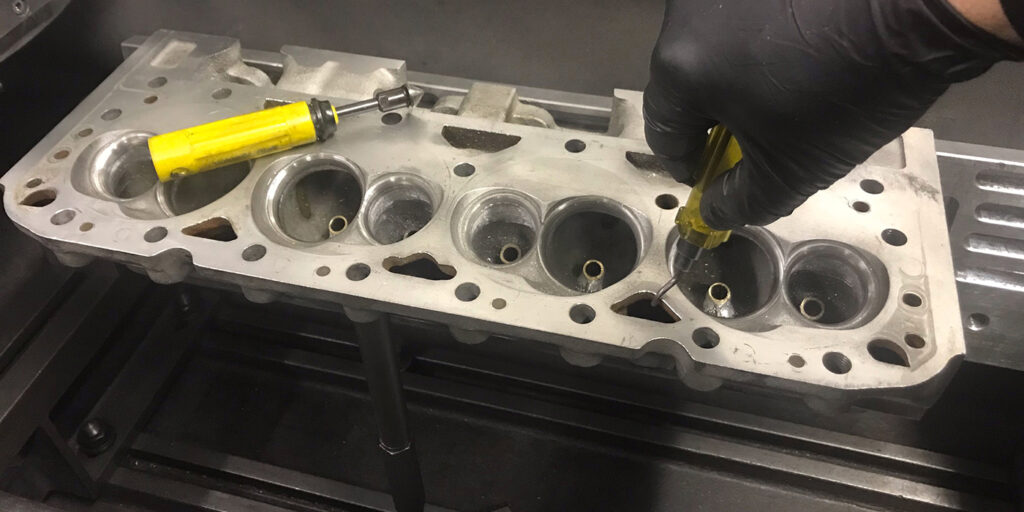

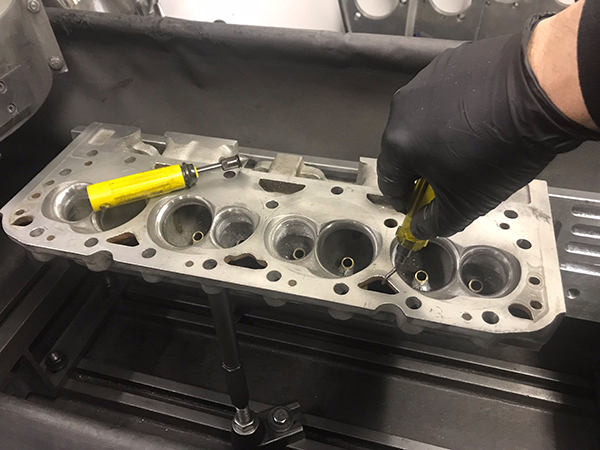

CLEAN CUT

When surfacing blocks or heads, it’s a good idea to deburr all the water jacket and bolt holes before making cuts. Many heads have scale and residue on those areas that can cause “drag” marks when the tool bit passes over. Marine heads, or any head that’s not thoroughly blasted can give problems. It reduces tool wear as well. Of course, a quick final deburr or chamfer is a nice finishing touch.

Ron Flood, Cedar Machine, North Branch, MN