The Chevrolet LT engine family from General Motors is rooted in the early ‘70s, when the LT1 was featured in the Corvette and Camaro Z28. After a 20-year hiatus, GM reintroduced the platform in the early ‘90s. The “LT1 350” came out in 1991, and was distinct from the high-output Gen I LT1 of the 1970s. It displaced 5.7L (350 cu in), and was a two-valve per cylinder pushrod design. The LT1 used a reverse-flow cooling system, which cooled the cylinder heads first, maintaining lower combustion chamber temperatures and allowing the engine to run at a higher compression than its immediate predecessors.

In the couple decades since the return of the LT1, the LS engine family has largely been the go-to for engine builders as the aftermarket part availability of the platform is unmatched. The legacy engines are simple, compact and respond well to extensive modding. On top of that, they are very reliable and their stock bottom ends can handle a lot more power than people give them credit for. Ease of access is another factor.

All that being said, the last five years or so have considerably closed the LS vs. LT gap. Today, the LT engine is in its fifth generation, and the platform continues to evolve. While LS may still be the gold standard, the LT has a few benefits that are making it a clearer option for builders who are looking to make considerable and efficient horsepower.

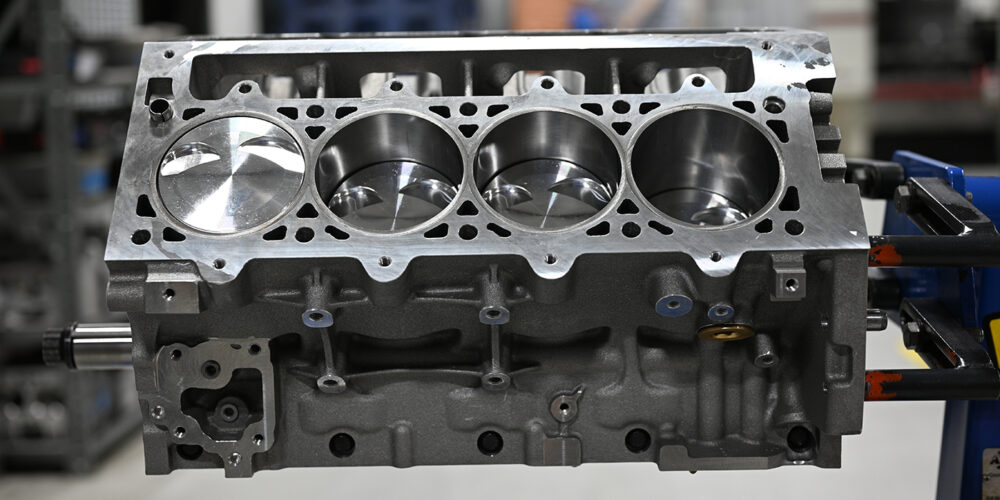

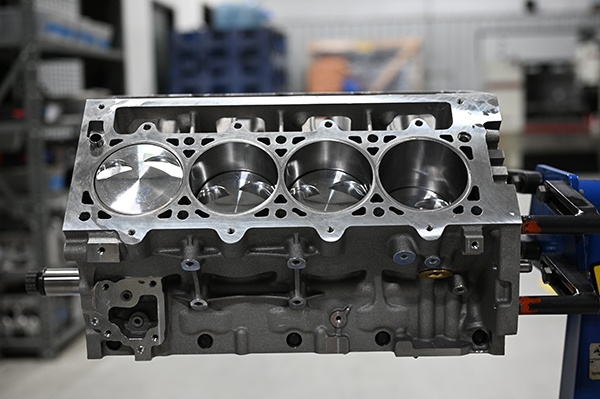

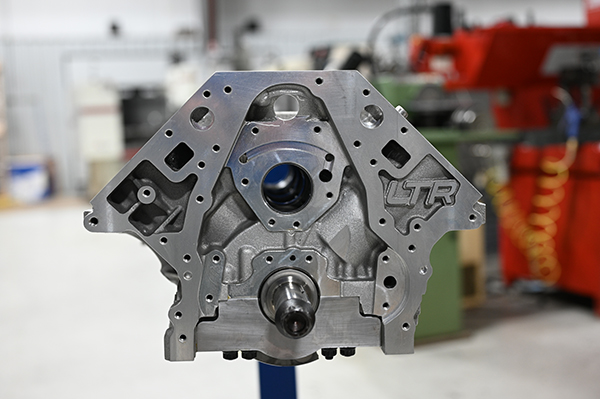

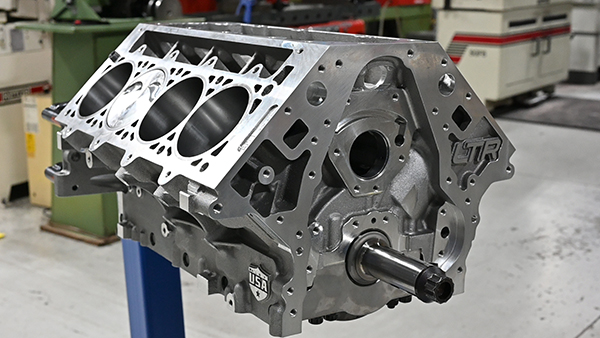

Late Model Engines, one of the most renowned shops in LS and new LT engine development, is currently working on a build for a customer that not only shows off the potential of the LT engine, but the new tech being developed for the platform. The build is centered around Concept Performance’s new LTR block, which is the first aftermarket as-cast aluminum Gen V LT block.

Concept Performance has been around for nearly 20 years as a behind-the-scenes, private-label manufacturer supporting a number of brands. Most notably, they made news half a decade ago with the release of their LSR block, which took all of the best features of the proven GM LSX and wrapped it into an aluminum offering.

Now, Concept Performance has taken what it learned with its LSR and applied those features to the new LTR block. According to specs from Jeremy Nichols and LSX Magazine, the bottom skirt wall of the LTR block has a minimum thickness of 0.750” and the bulkheads have a 0.500” radius where they connect to the skirt. As with the LSR, the new LTR comes with billet main caps that feature a six-bolt design using a 10mm cross-bolt, with all of the hardware coming from ARP.

The top of the block features an 0.800” thick deck that has the ability to accept six-bolt LT cylinder heads. The lifter valley has been gusseted for added strength, but still allows for adequate oil flow, and the lifter and camshaft bores come finished. The camshaft bores can be machined to accept up to a 60mm cam bearing, and Concept Performance leaves 0.003” for crush in the mains and 0.020” on the deck for final machining.

“This block looks really promising,” says Late Model Engines co-owner Bryan Neelen. “It’s going to be a gamechanger for all the guys who want to keep an aluminum block, but still make power. This is the first engine we’re building with this new block, so we’re excited to see where it goes.”

Neelen says that the current build should make around 1,500 horsepower to the tire once completed. But first, the LME team addressed a couple lingering LT platform issues, as it does with any of the shop’s engine builds.

“On these big-power builds, we try to get away from the factory cam phaser unit,” he says. “We get rid of the VVT completely, even in locked out applications. Instead, we machine a billet front cover that utilizes a solid cam gear and the front cover puts the cam sensors in the correct location to read that different gear.”

Neelen then couples this with a custom, billet, timing chain guide that replaces the factory timing chain tensioner, which has a piece of spring steel that’s prone to breaking. The tensioner is sealed to the factory oil pump, so it can’t simply be removed.

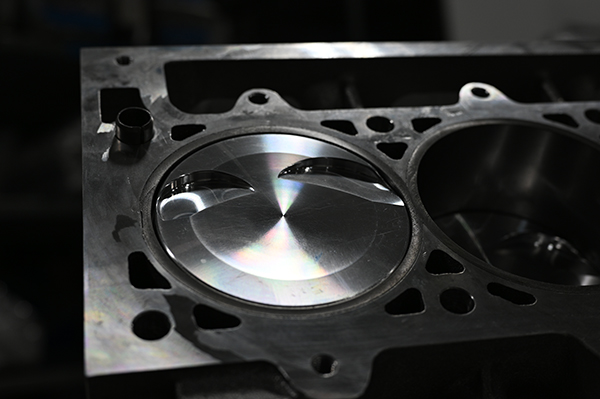

After going through LME’s proprietary balancing and blueprinting process, the team decided this LTR build would receive a Callies Magnum 8-counterweight crankshaft with a 3.750” stroke. The crank is connected to custom 4.125” bore Diamond 2K pistons with anti-friction coating on the skirts and lateral gas ports. The Diamond pistons also feature a .927” wrist pin and are mated to a set of Dyers H-beam connecting rods. The rods are manufactured from 300M steel forgings, which are 20% stronger than 4340 steel. The rods are a 6.125” length and have a 2.100” rod journal.

From there, the LME team needed to choose cylinder heads, and LME has plenty of options. The choice was made to utilize a set of LTX race heads, which are an Edelbrock casting that gets shipped to the shop in raw form. LME then CNC machines the heads to their finished form for maximum performance and adds all the valvetrain component goodies.

“We run a 2.180” intake valve and a 1.630” exhaust valve,” Neelen told us. “The factory LT4 heads have a 2.125” intake valve and a 1.600” exhaust. We were able to raise the ports up on these heads and extend the intake flange out a little bit and get a little bit better roof angle of the port due to raising the spring pockets up a bit.

“We also run a longer valve spring and it will have a low lash roller. We’re running a 1238x spring and it’s going to have about .720 lift on the cam. We’ve got a Victory1 Performance intake valve and an Inconel exhaust, and then we can set the heads up with a pedestal mount and a set of Manton billet rockers.”

Oil for the engine will be supplied via a Katech high-capacity scavenge, LT dry sump oil pump. Coming in at 400 cubic inches with a 10.5:1 compression, this LT engine will feel right at home under the hood of the C7 Corvette it’ll be dropped into.

In fact, any Corvette or Camaro owner should be excited about the notion of this new LTR block. It will be interesting to see the end result of this particular build, especially due to it being one of the first ever utilizing the new LTR block from Concept Performance.

While LME says it expects 1,500 horsepower to the tire on this build, the Concept Performance folks say well north of 2,000 horsepower isn’t out of the question. The bottom line – it means LT engine fans can up the ante just a little bit more! EB