Most aftermarket ECUs offer a choice of two tuning strategies – Speed Density or Alpha-N. Choosing the best strategy for your application will ensure that the correct fueling and spark event is applied to the engine. This article will guide you toward which one is the best for you.

The Speed Density tuning algorithm is by and large the most popular option and is a requirement for any boosted application. Speed Density senses “load” which can vary even when at the same throttle position and rpm. Speed Density uses a MAP sensor to measure engine pressure (vacuum or boost), which in essence is an electrically controlled vacuum gauge, and for the most part provides exceptional fuel control at multiple load, rpm and TPS positions. MAP sensors that can measure above atmosphere such as a 2 Bar or greater are required to read boost pressure in order to supply the correct fueling to the engine.

As important as Speed Density is for correct fueling for boosted applications, another major benefit is timing control. The ability to ramp out timing as pressure increases can be just as important as fueling in order to keep the engine happy.

Alpha-N, on the other hand, is hardly ever used due to the limits of only having TPS and rpm as the inputs which can negatively affect proper fueling. Imagine a steady-state cruise down a flat road at a steady rpm and TPS position, with the fuel correctly set at an ideal target air/fuel ratio. As you encounter a slight uphill grade in the road, naturally the load on the engine increases, requiring more fuel. If you keep the same TPS postion, the ECU will not provide the additional fuel required to cover the load and the engine will go lean since the fueling is currently set for a no-load cruise.

We may not realize it, but as we drive down the road, the load on the engine is very dynamic, constantly increasing/decreasing changing the fuel demand of the engine. In the Alpha-N tuning strategy, one would never be able to match the fuel control offered by Speed Density and we would observe more aggressive lean and rich spikes.

If it is acknowledged that Speed Density offers the best control for part-throttle cruise, wide open throttle and boosted applications, why is Alpha-N even an option? In previous generations of aftermarket EFI ECUs, the available map resolution for the fuel and timing tables made it difficult to provide the control needed for engine combinations such as those with large camshafts. Also, during the introduction of IR manifolds (such as a Hilborn Individual Runner) into the mainstream, Alpha-N was employed to fix idle and part-throttle fueling issues encountered in Speed Density.

As the available resolution for the fuel and timing tables increased, the need to use the Alpha-N tuning strategy with these combinations waned. When it comes to the Hilborn, Starr Performance and Consulting created techniques to synchronize the butterflies providing a new part-throttle driving experience with an IR manifold eliminating the need to use Alpha-N. It was Speed Density for all!

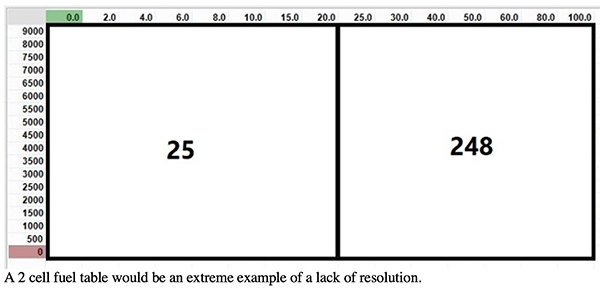

Stepping back to look at table resolution and what it entails, consider this extreme example. Imagine a 1Bar fuel table with only two available cells for fueling.

In this case, the lack of table resolution would result in extremely poor fuel control as we transition between different loads and rpm. One could imagine the lean stumble and over-fueling issues encountered as you move through the map under various loads. Increasing the resolution simply implies there are more cells to transition through as we accelerate and decelerate, therefore providing greater fuel control.

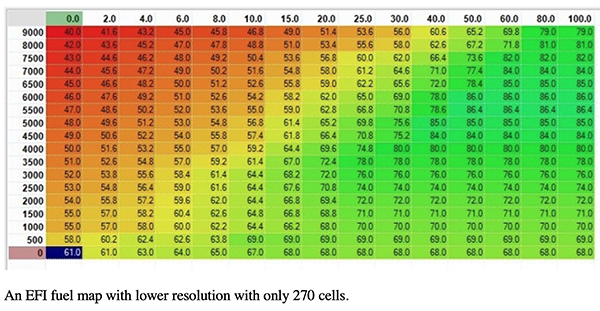

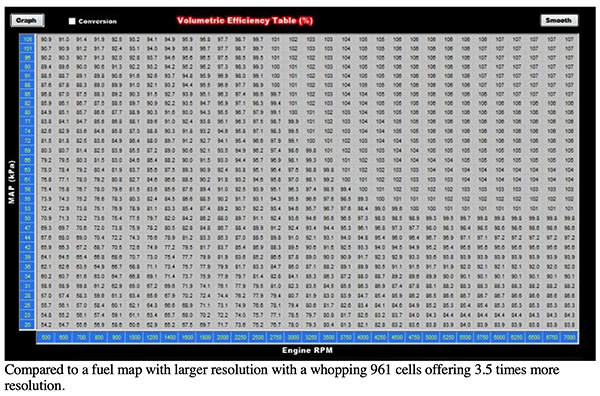

The examples below illustrate the difference in resolution between various ECU fuel tables.

Some EFI systems allow for Alpha-N/Speed Density blending where the mapping consists of Alpha-N control at the idle area, which transitions off idle to Speed Density at a user-defined point. And much like Alpha-N tuning in general, this algorithm is hardly ever used.

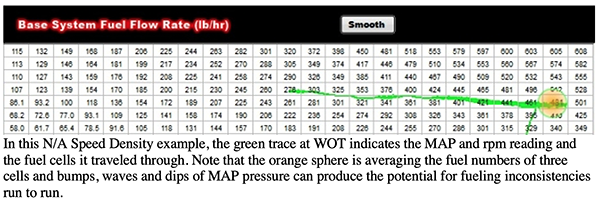

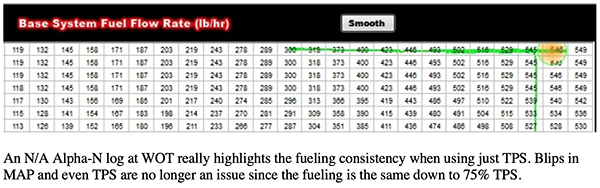

But could there be applications where Alpha-N may be a superior tuning algorithm over Speed Density? When it comes to N/A applications such as Pro Stock, Comp Eliminator, Drag and Drive competition and even nitrous racing, I do believe so. EFI is all about fuel control, and the more control we have to supply the correct amount of fuel to the engine, the more power we are going to make. When racing down the track at WOT, the ECU is tracking across the fuel map blending between the load and rpm axis, and typically as rpm increases, so will the fuel. If the map signal fluctuates, the fueling will not be consistent through the rpm range. Instead, it will add or subtract fuel. One may never see this slight change in fueling in the O2 readings, although it is easily spotted by looking at the pulse width numbers.

This scenario of adding or subtracting fuel, whether it be all cylinders or just one, can hurt power and in the event of a nitrous combination, can make finding the ideal tune-up more challenging. Alpha-N completely eliminates the potential MAP movement through load ranges ensuring a smooth transition through the rpm range.

More recently than ever, I have experienced performance issues with MAP sensors in N/A applications that just don’t seem to manifest themselves in boosted applications. These issues include a drop in MAP signal as rpm increases, lower than expected WOT pressure readings due to weather changes and flat out failures. Is it a quality issue, built in obsolescence or just plain bad luck? I’m not sure, but swapping into Alpha-N tuning saved the day, and in some instances, helped performance. The potential for having a MAP-related issue in the final round can be eliminated just by choosing Alpha-N for these combinations.

Having the ability to choose between Alpha-N and Speed Density gives the racer, as well as the street driver, the option best suited for the them.

Andy Starr, Starr Performance and Consulting – www.StarrPerformanceTuning.com