In the intricate world of high-performance engine building, each element holds significance, and the pushrod is no exception. This seemingly straightforward component wields a profound influence on engine performance, endurance and overall robustness. Engine builder professionals recognize that the careful selection of pushrods can make all the difference in the relentless pursuit of peak performance.

The bedrock of pushrod selection resides in the materials employed, a critical factor in pushrod performance. Three primary materials are used: steel, chromoly steel and aluminum.

Steel pushrods are ubiquitous in stock engines, are cost-effective and are characterized by limited strength and unimpressive weight characteristics, making them suboptimal for high-performance demands.

Chromoly steel pushrods are the preferred choice for performance engines because they outperform their conventional steel counterparts in both strength and weight considerations. Their reduced mass translates to valvetrain efficiency and durability.

Finally, aluminum pushrods are the lightest weight option, so they serve with distinction in racing applications where shedding valvetrain mass is paramount. However, they may exhibit diminished endurance compared to both steel or chromoly.

Material selection must be matched to the engine’s precise requirements, considering variables such as power output, engine rpm range and budget.

Moving on from material considerations, figuring out proper pushrod length warrants meticulous attention. Precision length determination entails measuring the distance from the lifter cup to the rocker arm cup during the lifter’s dwell on the base circle of the camshaft lobe. Many people opt to use adjustable pushrods to fine-tune this critical dimension. Pushrods that deviate from the “green zone,” whether too short or too long, introduce instability into the valvetrain, which can undermine engine performance.

Determining the correct pushrod length is often regarded as one of the most intricate aspects of the selection process due to the variability in valvetrain geometry and design. To tackle this challenge, let’s clarify some terminology.

First, overall length of the pushrod is the measurement encompassing the very tip of the ball or cup on each side. It’s essential to note that the presence of oil holes in the pushrod ends can slightly affect this measurement, depending on the hole’s diameter.

Next, theoretical length represents the pushrod’s length as if it had no oil holes in the ends. Finally, effective length is a measurement that holds particular relevance for cup and ball-style pushrods due to potential differences in cup depths among manufacturers, which can be as much as .060”. The effective length is determined by measuring from the contact point on both ends of the pushrod, from the bottom inside the cup to the tip of the lifter end. To achieve precision, you can calculate it by subtracting the cup’s depth from the overall length. Alternatively, by placing a ball bearing of the correct size inside the cup and measuring the overall length over the bearing, you can obtain the same result.

“Perfect pushrod length is better than compromised pushrod length,” says Trevor Manton of Manton Pushrods. “Now more than ever it’s critical to get that length right the first time to save time and money. If the motor doesn’t start because of a lack of compression, you didn’t choose the proper length pushrod to preload the lifter and you hang the valve open because the pushrods are too long.

Selecting the proper pushrod diameter is also important. Diameter selection should mirror the engine’s specific needs, with larger diameters allowing heightened rigidity and robustness. The wall thickness indicates the pushrod’s weight and durability, with thicker walls augmenting strength at the expense of mass. This delicate balance must be struck to avoid unwarranted weight penalties while ensuring structural integrity.

“If you just use the .025” increments in length, when a lifter like a Johnson calls for a tolerance within .010” a +/-5, you’re creating yourself a much higher likelihood of having a problem with something else related to the lack of perfect pushrod length. And, make sure your camshaft is at base circle. Also make sure that if you have an adjustable rocker arm that you have the adjusting screw where you would desire the screw to be at when you actually set lash.”

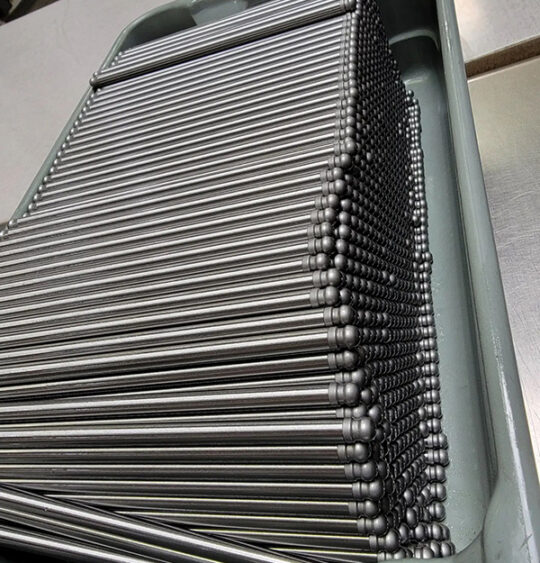

Manton can create and produce a pushrod or rocker arm adjusting screw stronger, more durable and suitable for a customer’s engine needs. All of their products are made from quality materials – tubes are made of 4130/4135 seamless chromoly or cold working tool steel and are available in a variety of heat-treated conditions. This allows Manton to manufacture a pushrod to enhance specific applications.

Another crucial aspect of pushrod selection is determining the appropriate ball and/or cup configuration. To determine the correct radius for each end of the pushrod, precision measurements using radius gauges are recommended. Measure the radius of the lifter’s pocket and the ball or cup on the rocker arm that will be employed. Another technique involves checking whether the ball and cup ends match by fitting a known-correct pushrod’s ball end into another pushrod’s cup end.

Selecting the proper pushrod diameter is also important. Diameter selection should mirror the engine’s specific needs, with larger diameters allowing heightened rigidity and robustness. The wall thickness indicates the pushrod’s weight and durability, with thicker walls augmenting strength at the expense of mass. This delicate balance must be struck to avoid unwarranted weight penalties while ensuring structural integrity.

“Diameter and material grade will drastically increase the strength, while wall thickness will incrementally increase the strength,” Manton says. “And heat treatment is just another option to make your setup even better. Outside of added cost, there aren’t really too many negatives to heat treating.”

Surface treatments such as heat treatment and black oxide coating hold the potential to confer elevated durability and heightened wear resistance upon pushrods. These treatments mitigate friction within the valvetrain and extend the operational lifespan of the pushrod.

Builders must also consider what design of pushrod they prefer. One-piece pushrods are created from a solitary material piece that imparts these pushrods with unparalleled strength and endurance, making them the favored choice for high-performance racing engines. Two-piece pushrods are composed of two distinct sections conjoined. These pushrods, while lighter, sacrifice some structural integrity, finding their niche in less demanding applications.

“Though the strength of a one-piece pushrod might seem obvious over a two-piece pushrod, a multi-piece pushrod is often stronger than a one piece because you can tailor your engineering choices for the center section to be stiff and the ends to be a good bearing surface,” Jordan Manton says. “With a one piece you have to find a middle ground that will be rigid but also a good bearing surface. The main advantage of a one piece is cost.”

The selection of an optimal pushrod for a performance racing engine mandates many considerations of material composition, length, diameter, wall thickness, design, and surface treatment. Each facet is pivotal in dictating the engine’s ultimate performance and endurance. Obviously, there’s a lot to consider, so consultation with seasoned experts and collaboration with reputable manufacturers is paramount for informed decisions that translate into victory. EB