Chevy Balancer Fixture

I use a harmonic balancer installation tool for big and small block Chevys and just flip it around to mount on my lathe. Easily remove .010”-.015” wear groves or polish poor-quality surfaces like new.

Derek Ludington

Ludington Engines

Zumbrota, MN

It Cleans Intakes Too

I use WD-40 to clean the sickly intake residue out of intake manifolds and intake runners in heads on today’s injected engines. Spray it on and scrub it out with a cloth before you put it in your aluminum or steel tanks to clean and it comes out with clean intakes and runners that tank solutions didn’t touch.

Steve Mulder

Mulders Auto Machine Inc.

Boise, ID

Angle Milling Fixture

Use 1-2-3 or 2-4-6 blocks to quickly make a fixture for milling and or drilling parts at an angle. Set the angle with triangle blocks, a sine bar, or machine a custom-angled piece of aluminum (as in the photo). A dowel pin serves as an X-axis part locator, while the vertical 1-2-3 block acts as a Y-axis part locator. Note that while only one C-clamp is shown holding the part (red clamp), at least two clamps are recommended.

Tom Nichols

Automotive Machine & Supply, Inc

Joshua, TX

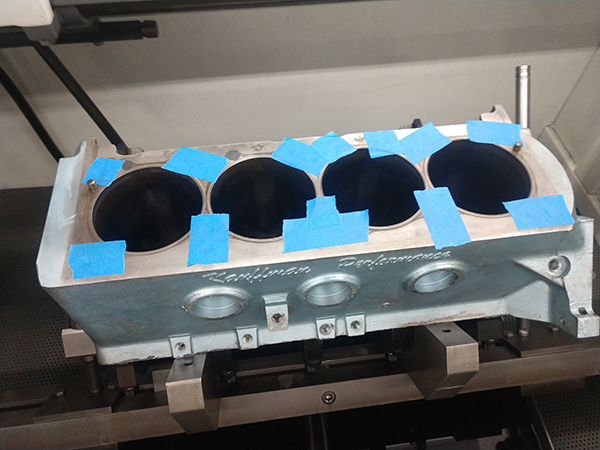

Painter’s Tape Trick

When I only have one torque plate, I tape up the other side to keep the honing oil out of the holes and water jacket. Then, when I switch sides, I wipe off the top I just did with thinner and tape up that side. If I’m not using torque plates, I tape up both sides and trim out the bores. I use painter’s tape, which comes off easily and doesn’t leave any glue residue. I get much less oil in the spray washer this way.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

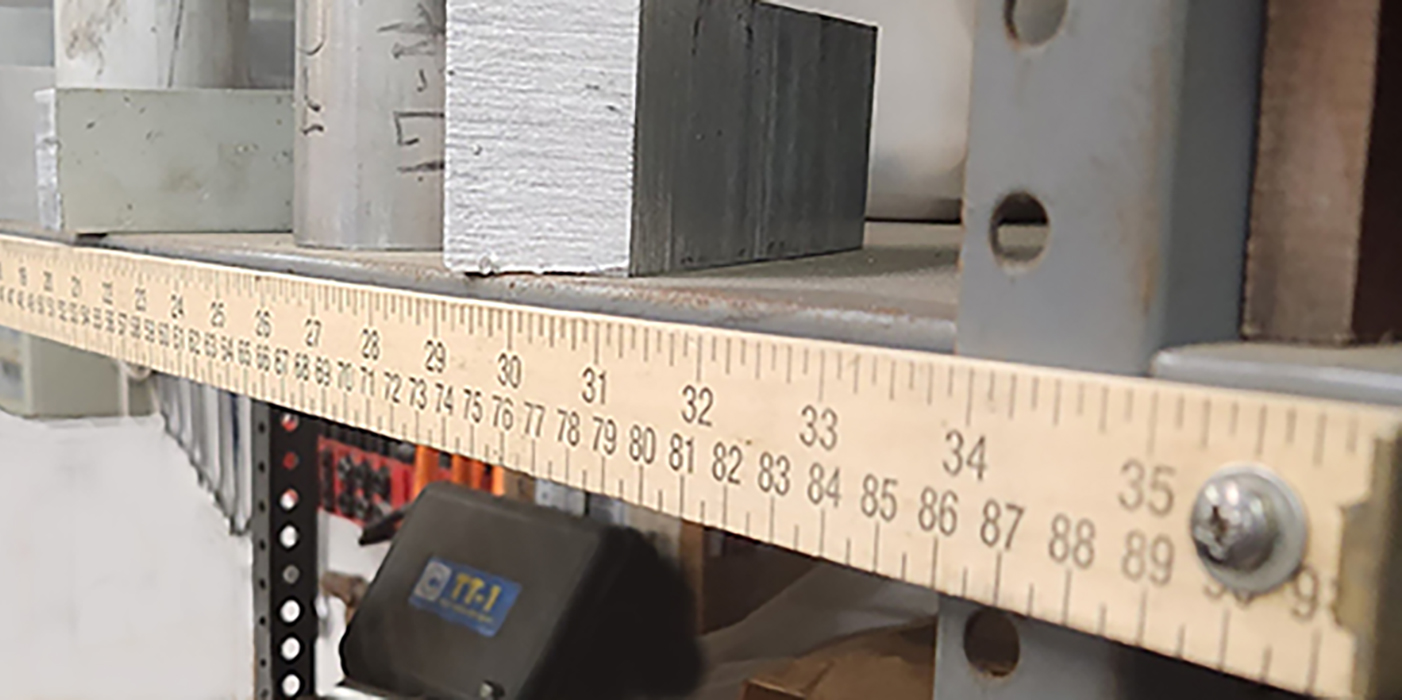

Lathe End Stop

This is an end stop I made for the lathe. It uses a couple of o-rings to friction fit it into the head stock tube. It works great for machining cut-to-length pushrods, studs or whatever you need to be duplicated quickly. I did two sets of pushrods with it last night and they were all within .001”.

Ron Flood

Cedar Machine

North Branch, MN

Priming the GM LS Oil Pump

Priming your oil pump and your engine before startup is very important, but it is often difficult on engines with a front crank-driven oil pump. Here is where a pressurized oil priming tank is handy. It is common with the GM LS engines to replace the pump in the car. Here are some important steps that need to be addressed before starting the engine.

The LS oil pick-up screen is attached to the bottom of the pump and sealed with an o-ring. It is important that the correct o-ring be installed, or air may leak in and cause severe engine damage. Use engine oil to lubricate the o-ring and install it on the pick-up tube, then install the tube to the oil pump. This is a good time to install a new pick-up screen rather than chance getting any debris from the old screen into your new pump that can easily cause a by-pass to stick, creating a low or no oil pressure condition.

When installing the pump, it is important to locate the pump and install the locating bolts just finger tight. Once all the bolts are snug, torque the bolts to the correct torque spec, working around the pump in a star pattern. It is time to complete the engine assembly. Make sure your oil level is correct and fill the new oil filter with new clean oil before installation.

To prime the pump, use an 8mm Allen wrench to remove the oil galley plug on the left, lower, front corner of the block. Use a 2-ft. long length of 3/8” I.D. fuel hose and screw it about an 1.5” into the hole where you just removed the plug. Slowly pure about 8 oz. of engine oil into the hose via a funnel. Wait about 3 minutes, remove the hose, and replace the oil galley plug. Your pump should now be primed and ready for the engine to start. If you do not have oil pressure right away, shut down the engine and do not start it again until you have corrected whatever has caused the problem.

Engine Pro Technical Committee and Melling Tool Company