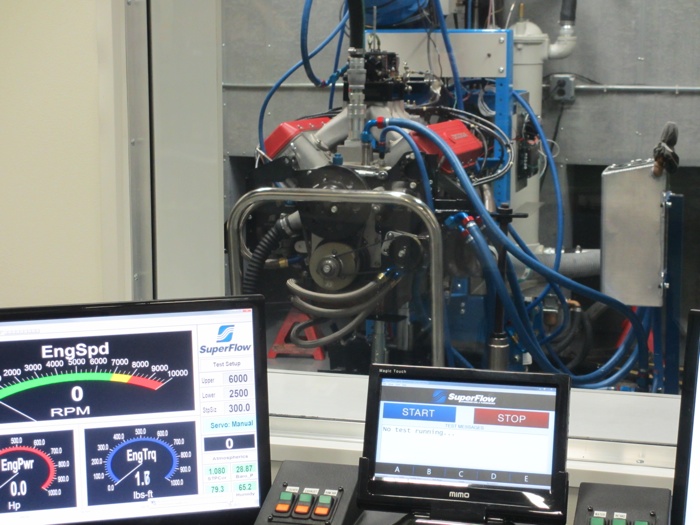

Dynamo Dynamometers

Not every engine shop has one, but every engine shop could benefit from installing one. Sure, it can be expensive, it is loud, but engine shops with these in-house offer an extra source of income and the ability to test engines and parts. I’m talking about a dynamometer.

Performance V6 and Four Bangers

Any engine builder worth his or her torque wrench keeps their eyes open. They’re looking for anything and everything to make work easier, better and, of course, more profitable. When it comes to the number of cylinders in the motors they build, are they looking at performance-dedicated six and four cylinder engines as a viable source of income?

Choosing the Right Oil Pump

Choosing a replacement oil pump for an engine you are building or modifying is a process that requires some thought. Original equipment oil pumps are usually adequate for most stock applications – but some are not, especially if an engine is being modified.

DBB Acquisition LLC Acquires Dura-Bond Bearing Company

DBB Acquisition LLC has announced that it has completed the acquisition of Dura-Bond Bearing Company, a division of privately held Melling Engine Parts. Dura-Bond is a manufacturer of Cam Bearings, Bushings, Valve Seats and Hardware for engine and transmission rebuilding since 1947. The Company is based in Carson City, Nevada. Terms of the transaction were

Performance Diesel Upgrades

Why should you offer more when rebuilding a diesel engine? Because any shop can rebuild the OEM block or buy a direct replacement. However, rebuilding a diesel engine with slight power modifications will get you more customers and offer you higher profits because of the modifications made that not everyone can do or has the knowledge to do.

Champion Oil Announces Engine Builder Supplier Program

Champion Oil, Clinton, MO, has announced its new distributor program that allows engine builders to offer the complete line of Champion products to their customers.

Being Green Takes Some ‘Engine’uity

You might not have even realized, but by being an engine builder/rebuilder alone, you’re already contributing to making the environment a greener place. That’s right, it takes less energy and less material to rebuild an engine than it does to build a brand new one. So since you’re already being ‘green,’ why not go a few steps further?

Cleaning Engine Parts

Cleaning is a time consuming, expensive process for most rebuilders. According to Engine Builder’s most recent Machine Shop Market Profile, rebuilders say they spend more than 15 percent of their total production time in cleaning. Safer, less toxic methods continue to gain a foothold in today’s professional shops.

More Power Inside – Muscle Cars

There are many aspects of the famous and desired muscle car engines of the 1960s and ‘70s. They have become the holy grail of factory performance engines, but they are getting more and more scarce as the years go by. For car owners, the engines have evolved in recent years into three different configurations. Read on to learn more.

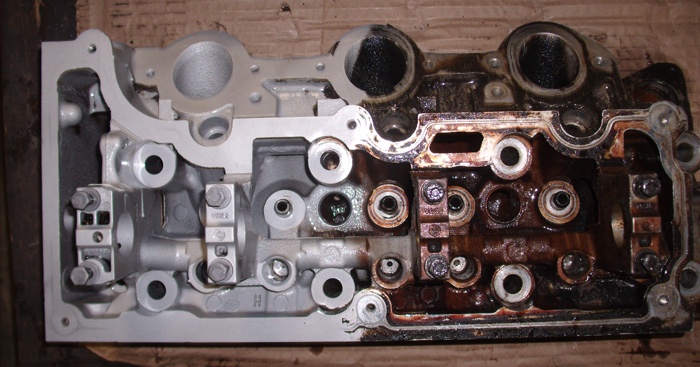

Engine Block and Head Repair

A cracked cylinder head or engine block may or may not be bad news depending on the size and location of the crack(s), the value of the casting and what it will take to fix the crack(s) versus what it would cost you to replace the casting. Read what your options are in this Larry Carley feature.

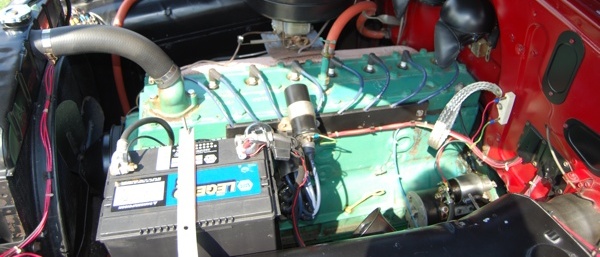

FE Dyno Pulls Show Benefits of Carburetors and EFI

We intended to dyno the engine two ways: first, we wanted to break the engine in and fine-tune it with a carburetor. Then, we would convert the engine over to fuel injection and compare power differences. This would be a great opportunity for a real-world comparison.

WIX Filters Celebrates FFA Week with Look at Agriculture Offerings

WIX Filters, a global manufacturer of filtration products, is celebrating National FFA Week by highlighting its foundation in and continued commitment to the agriculture industry. WIX’s legacy in agriculture spans 76 years, starting in 1939, when it began manufacturing oil filters specifically for farm tractor engines.

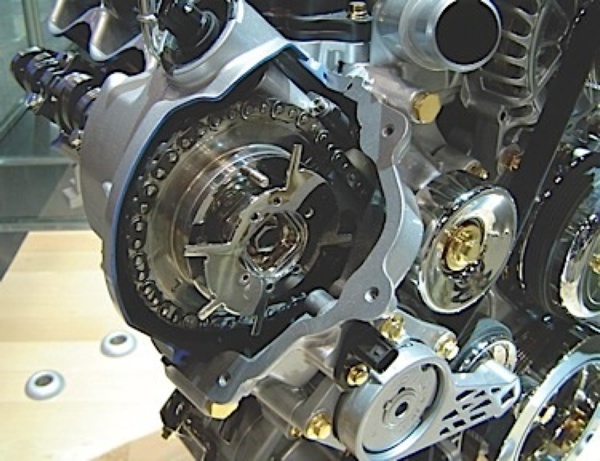

Ford 4.6/5.4L 3V Start-Up Noise

Some Ford vehicles equipped with a 4.6L 3-valve or 5.4L 3-valve engine may exhibit a ticking and/or knocking noise after reaching normal operating temperature, or a rattle upon starting. The noise may be described as ticks, taps, knocks, or thumps. In some cases the noise may be a normal characteristic of these engines. In other cases the noise may require further investigation.

Choosing the Right Camshaft for a Performance Engine

A camshaft is nothing more than a cast iron or steel shaft with a series of lobes strategically placed along its length. Each lobe opens and closes a valve by moving a lifter, pushrod and rocker arm, or in the case of an overhead cam engine by moving a cam follower or direct valve action. However, choosing the right camshaft is not only the cornerstone of building a performance engine, but also its centerpiece.

Wilmington Mile Engine Builders

In Bill Holder’s opinion, there’s no finer place to find unique engine builders than the long super-smooth runway at the former DHL facility at Wilmington, OH. This will be the third article in Engine Builder honoring these efforts.

The 392 Magnum V8 Build is a Wrap

The 392 Magnum engine build is a wrap. We’ve done all we can and now it’s going to power someone’s muscle car, hot rod or truck. When all is said-and-done the only things original in this 318 motor are a fully machined block, the cam thrust plate, the fuel pump eccentric and the bolt and washer holding on the harmonic balancer. Everything else is brand new.

DynoMax Adds High-Strength Torca Couplers to Performance Exhaust Product Line

DynoMax Performance Exhaust will release several new high-strength Torca coupler clamps on Jan. 1 that remove the need for pipe flares, slip joints or slotting, providing custom exhaust builders a serviceable joint and increased durability at the connection point of exhaust pipes. The new DynoMax coupler clamps are available in a variety of sizes.

The Unique Engines of ARCA

ARCA uses older style NASCAR Cup cars. Specifically, they are the ones used just before the advent of NASCAR’s Car Of Tomorrow (COT) in 2007. This means teams running ARCA can do so with a safe, well-built race car without paying top dollar.

Pontiac’s Straight 8s

The Pontiac L-head straight eight was used in production cars for 21 years between 1933 and 1954. This classic engine was advertised as a powerplant that could run 100,000 miles without a major overhaul.

Elgin Industries

Elgin Industries is celebrating its 95th anniversary this year, and from our founding in 1919 through today we have been dedicated to manufacturing world-class products for the engine rebuilding industry. Our founder, Martin Skok, was an automotive technician at an Elgin, Illinois-based vehicle dealership when he became frustrated with a serious shortage of high-quality replacement