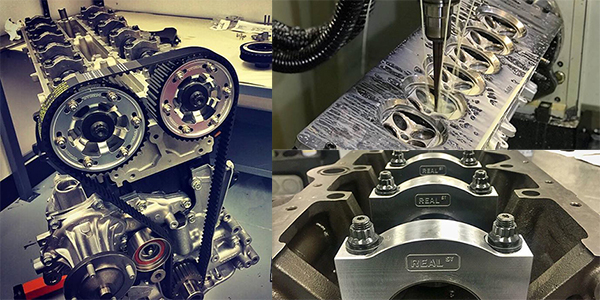

Machining Steve Morris’ SML Heads – Part 2

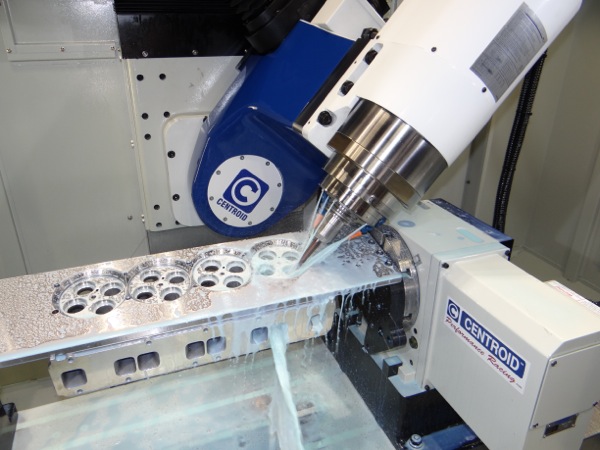

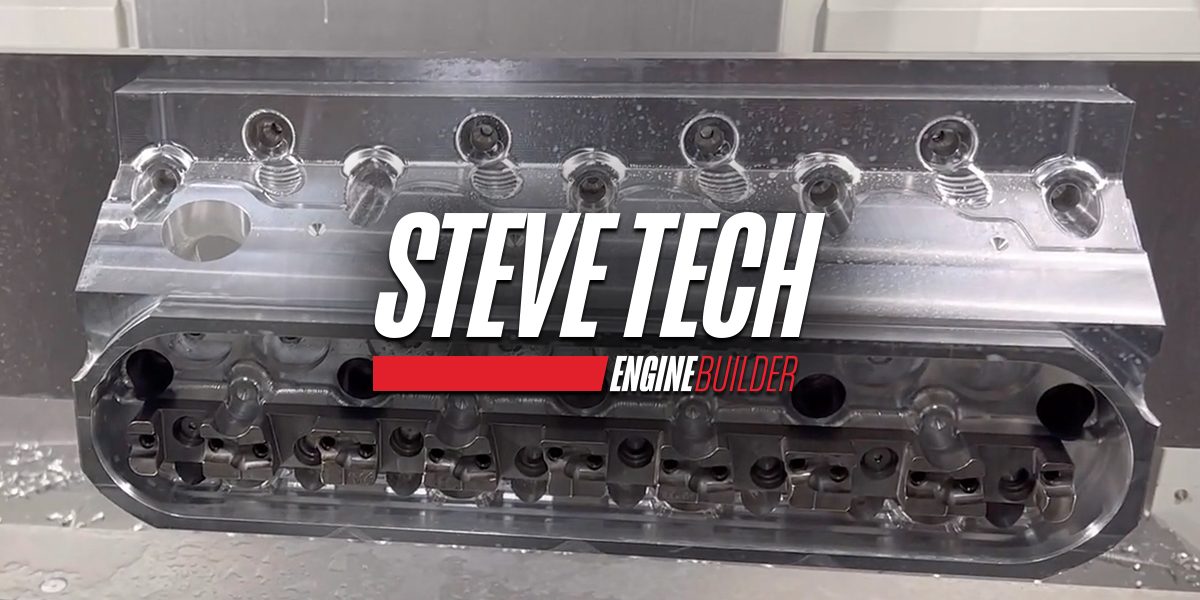

Now that Steve has everything setup in the 5-axis Centroid CNC, the real machine work has begun. Check out the progress on these billet aluminum heads.

Inside Look at Steve Morris Engines’ SML Heads – Part 1

As Steve continues to develop his SML engine platform, he gives us an inside look at the development of the cylinder heads, which start from a raw block of billet aluminum and turn into a work of art thanks to a Centroid 5-axis CNC.

CNC Machines: The Haves vs. Have-Nots

Now more than ever, there’s a need for the precision and speed of a CNC in three-, four- and five-axis configurations as well as lathes.

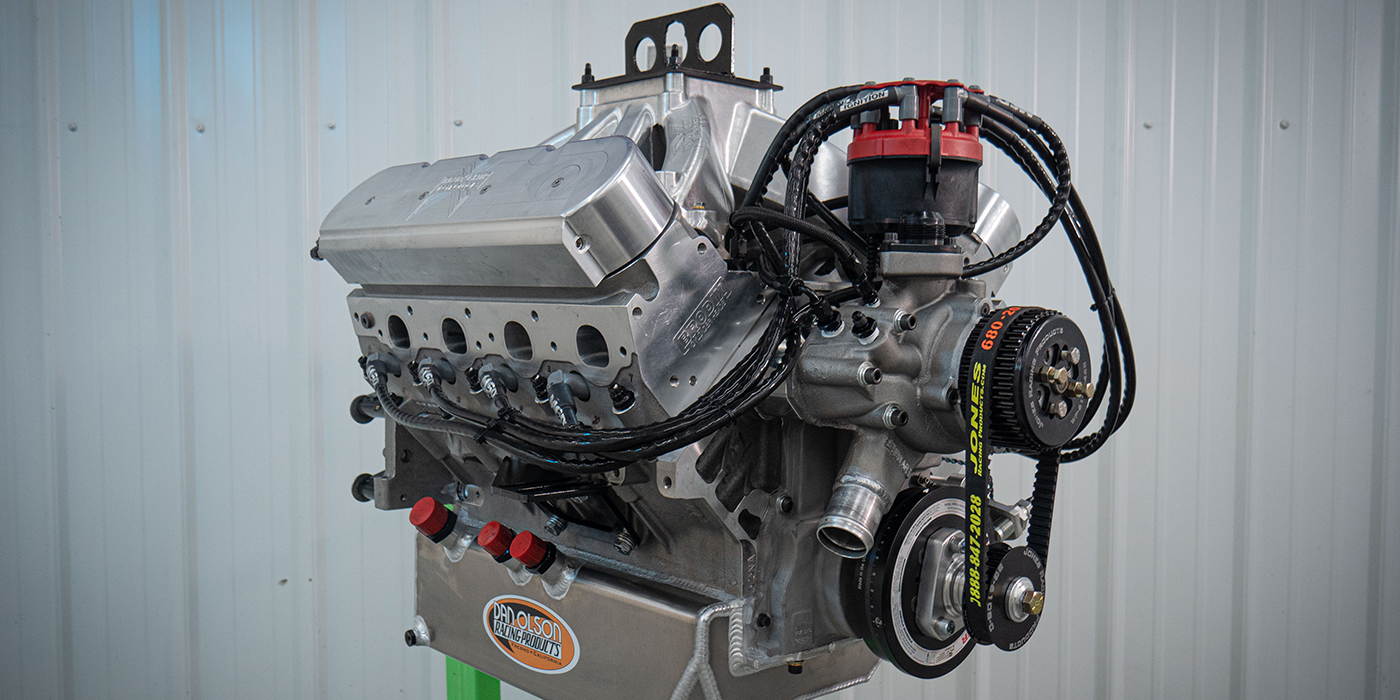

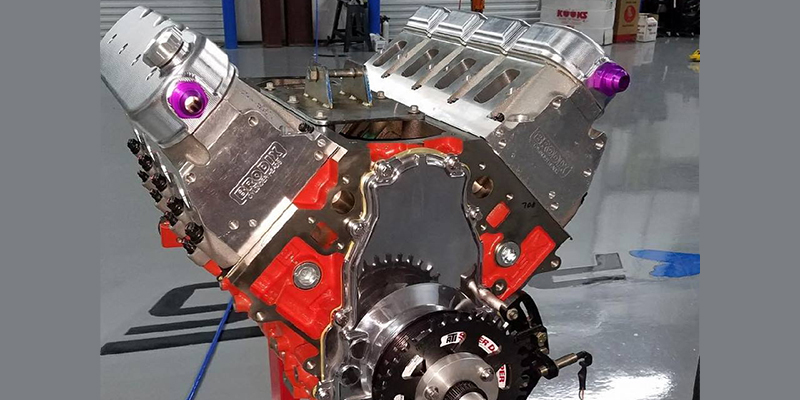

434 cid Dirt Late Model LS Engine

Blue Chip Racing Engines builds high-performance engines for super late models, UMP modifieds, super stocks, crate cars, and pure stocks, but one of its more popular engines is its dirt late model engine package – a 434 cid LS engine build. Offering nearly 900 HP, it’s not hard to see why. Find out what goes into the build.

Edelbrock Announces New Race Center

One of the most successful partnerships in the racing industry expands to create new capabilities with the Edelbrock Race Center.

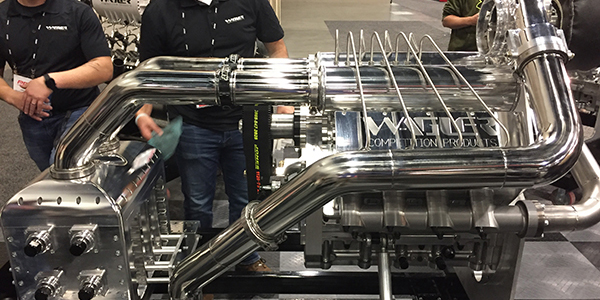

Mechanical Injected & Turbocharged DX 460 cid Duramax

There’s not much Wagler Competition Products isn’t capable of doing at its Odon, IN-based diesel engine shop. Evidence of all those capabilities can be seen in this mechanical injected and turbocharged DX 460 cid Duramax built for Pro Pulling Leagues. Find out what went into making this a more than 4,000 horsepower Duramax monster!

440 cid LSX Methanol Engine

After spending time as a Marine, Kyle Thompson returned to civilian life with a serious need for speed. He started Thompson Motorsports to feed his passion, and today the Texas-based engine shop churns out 550 engines a year like this 440 cid LSX methanol engine for radial drag racing! Find out went into this low 4-second engine build!

CNC Machine Centers

One curious fact that caught our eye in the latest Machine Shop Market Profile, published in June, was that 41% of readers – engine builders – don’t use a computer to run their shop. This begs the question: if you don’t use a computer for basic bookkeeping, are you using one for machining?

Finding Good Employees

There are very few problems in business today that transcend industry quite like finding good employees. It’s an issue at any office, in any industry, all over the country and even the world. That being said, there are few industries which have struggled to find good employees the way the engine building/rebuilding industry has.

CNC Machining Equipment

What’s Keeping You From Making the Plunge? I’ve discovered when I talk with Engine Builder readers about CNC equipment the conversation often falls one of two ways: it’s either the best idea in the history of the industry or it’s just too expensive, too complex or just too different. In conversations with equipment suppliers, on

Turbocharged Toyota 2JZ Engine

When this turbocharged Toyota 2JZ engine got on the dyno at Victory Precision Machine, it lost oil pressure. The problem turned out to be a spun bearing and a trashed crank. Frank Mangano got to work rebuilding this engine for a 1997 Supra street application. Find out how the build turned out!

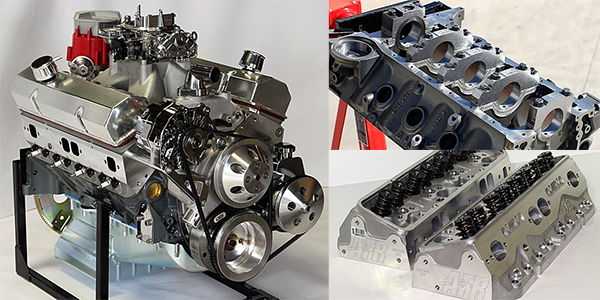

Skip White Performance 434 Small Block Chevy Engine

Skip White Performance is one of the biggest players in the industry pumping out an annual average of 900-1,000 engines each year. One of those engines, and one of the shop’s more popular models, is this 434 small block Chevy engine. Find out the details of what goes into this ‘All Out’ engine package.

Jeremy Wagler Named Diesel Engine Builder of the Year 2017

Opened in 2012, Wagler Competition Products (WCP) located in Odon, IN, is a full machine shop specializing in diesel work with a focus on the Duramax engine.

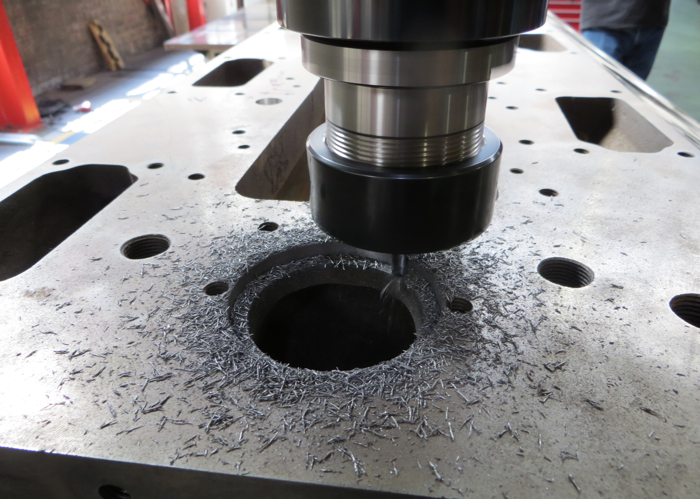

Why Cutting Fluids Are Imperative to Machining

In order to produce the best performing engines with tight tolerances and finishes, CNC machines require cutting fluids to perform at the highest levels. You might think a fluid is a fluid is a fluid, but you’d be wrong.

Wagler DX 460 Engine

Most of this Wagler DX 460 engine from head to toe gets brought in on pallets of aluminum and is machined into a complete engine. With hours upon hours of engine design and development Jeremy Wagler has this DX 460 engine singing to the tune of 2,500 hp.

FAQ About CNC – Can It Do What the Modern Machine Shop Needs?

To find out what kind of questions would-be buyers of CNC shop equipment typically ask when looking at CNC equipment, we interviewed the people who make such equipment as well as some shop owners who have bought CNC equipment.

Sourcing CNC Solutions – Making the decision for CNC may be scary, profitable

CNC machining equipment can be a double-edged sword to many engine builders that promises flexibility and profitability, yet often requires a significant upfront investment. As with any piece of equipment, there’s no “one size fits all” solution, and three top engine builders explain how they overcame the fear of financing and failure to find success

PRI Machinery Row Recalls 50 Years of Tooling Advances

Visiting Machinery Row at the annual PRI Show in Indianapolis you’ll see some mind-blowing whirring, spinning and rotating as machines like the Centroid A560 with CAD/CAM control, touch screen operation and a 24-tool automatic tool changer machine race car engines.

Modern Machining

Advancements in engine machining technology have truly moved this industry firmly into the space age. Highly developed abrasives and computer numeric controlled (CNC) software are found at almost every level of equipment, leaving some to mourn the loss of the “art” of engine machining in favor of the “science” of precision.

What Can CNC Do For You?

Are you using Computer Numeric Controlled (CNC) equipment in your shop? According to our most recent Babcox Machine Shop Market Profile Survey, 12 percent of engine builders said they own a CNC machining center (a multi-purpose machine that can do surfacing, boring, milling, drilling, etc.). The survey also asked what other types of equipment our